Process for treating sewage of oil field

A treatment method and technology for oilfield sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. environment and other problems, to achieve the effect of facilitating loading and pulling problems, speeding up settling speed, oil removal efficiency and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

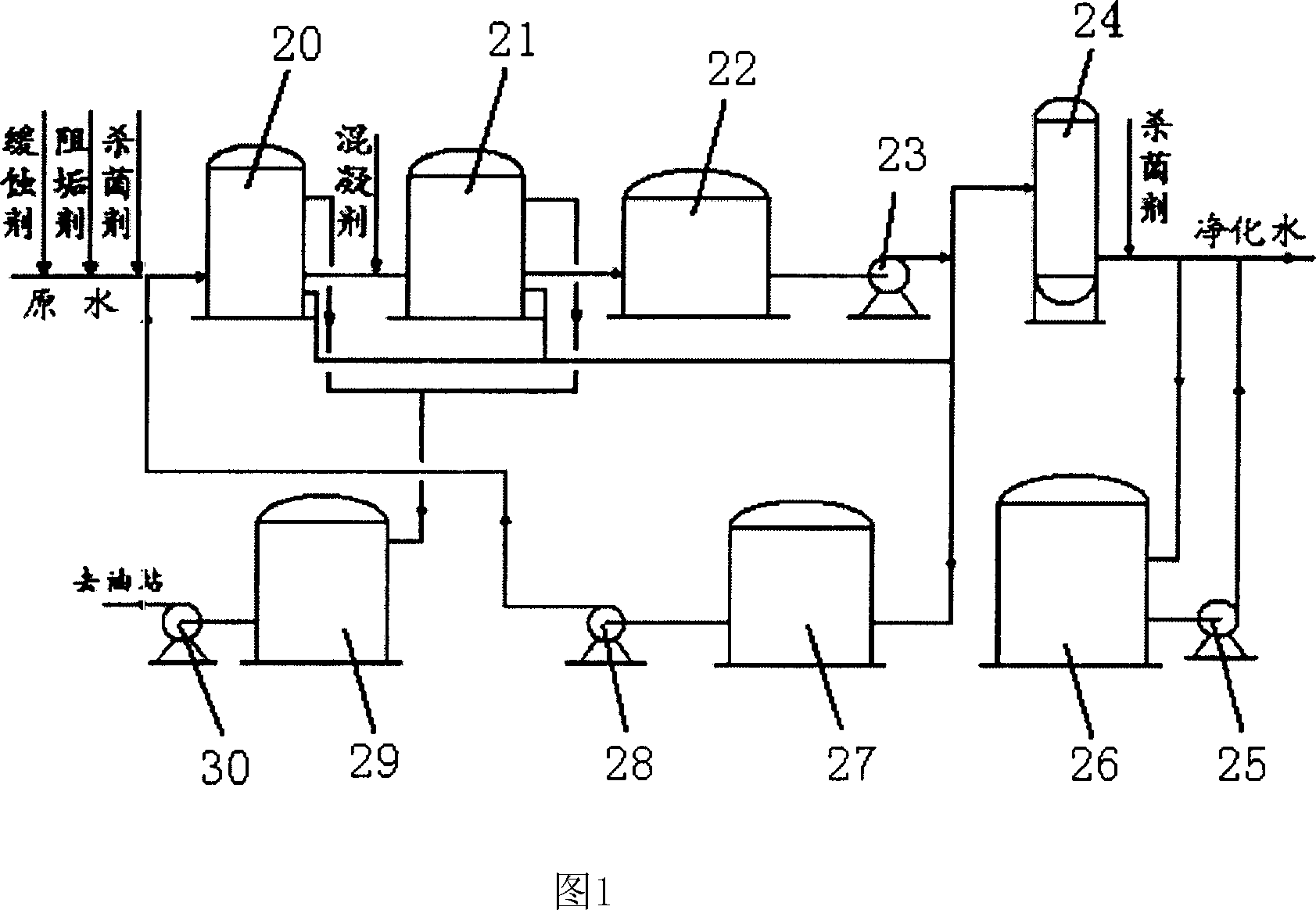

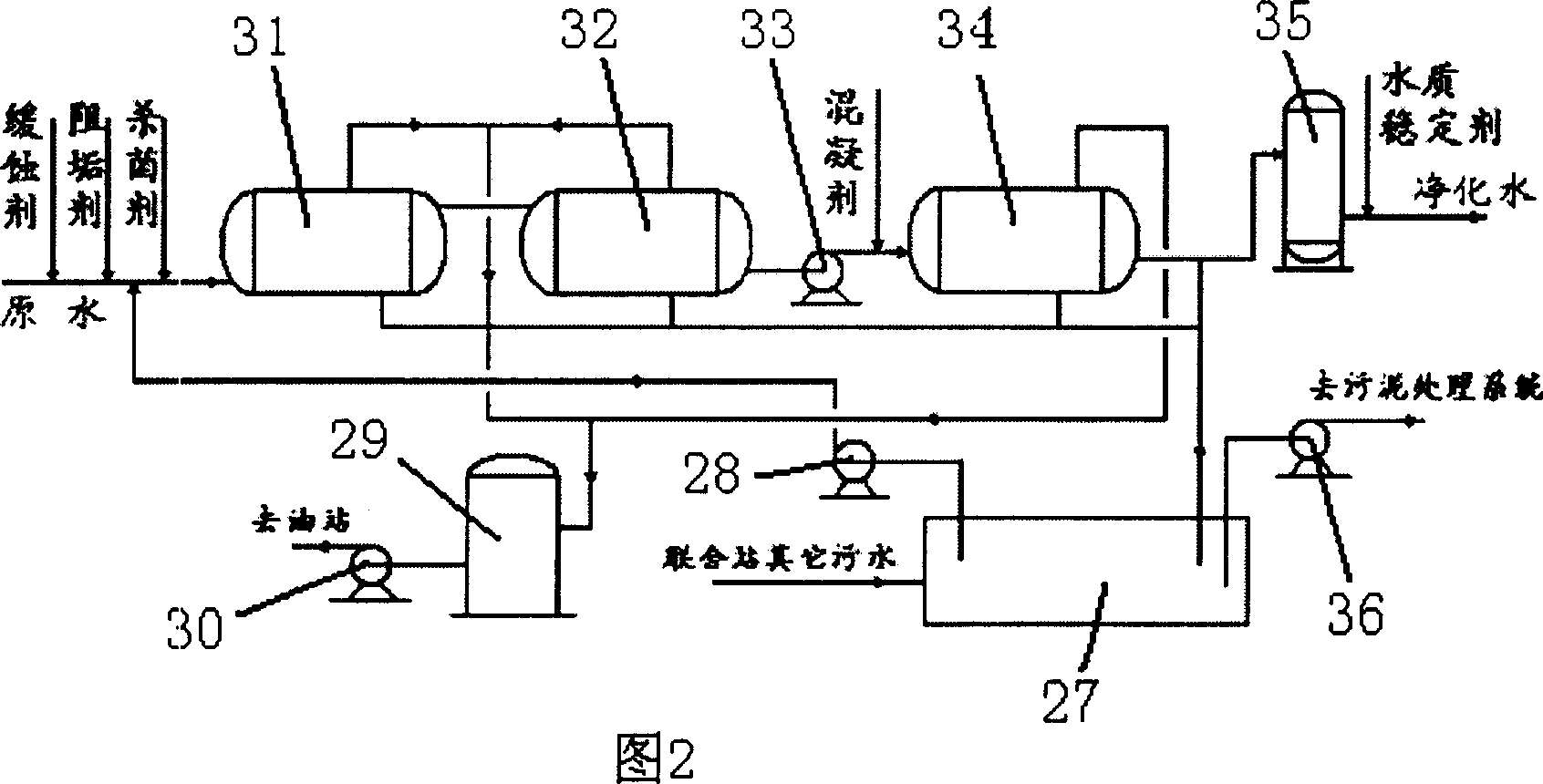

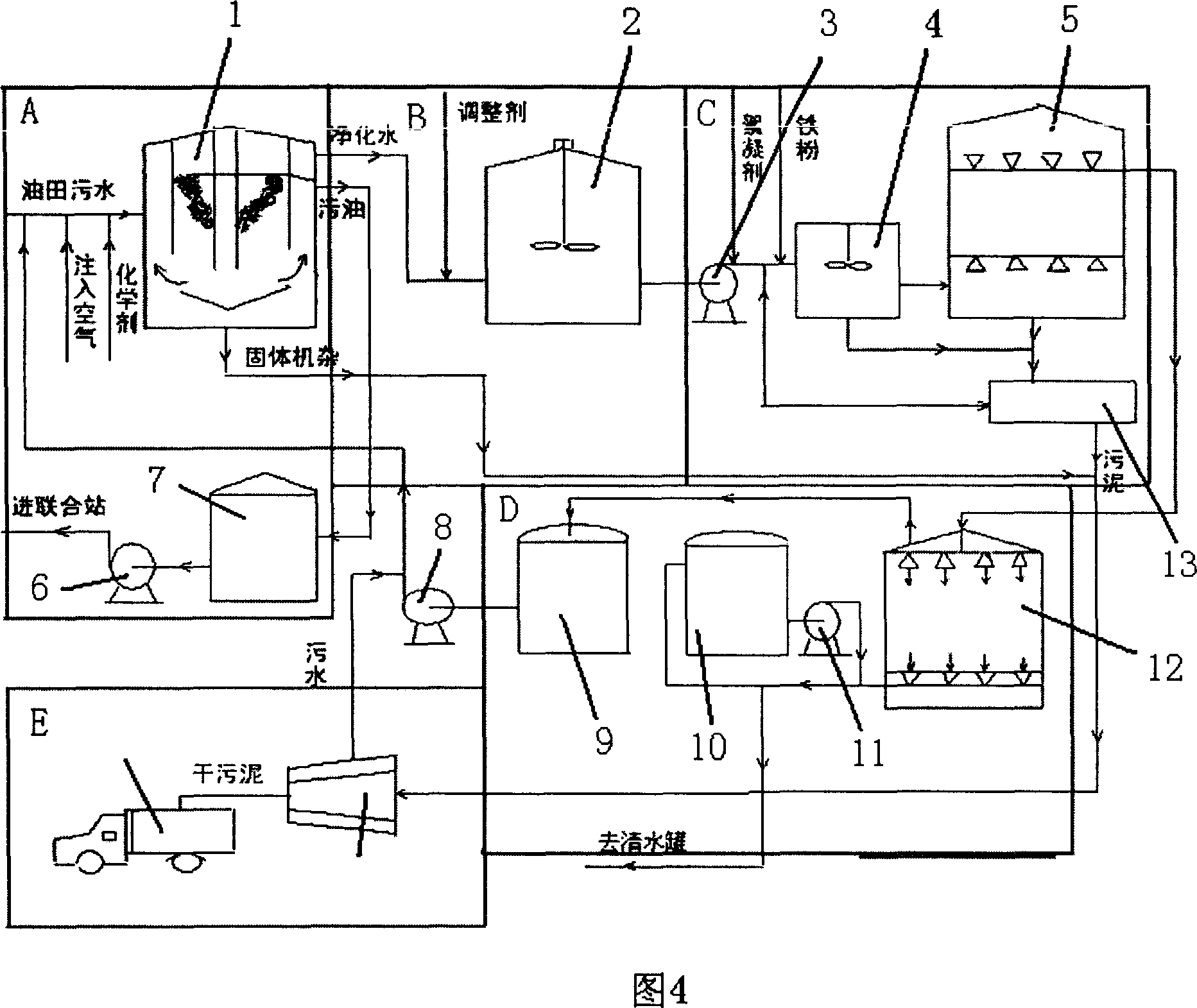

[0054] The air flotation degreasing process is adopted to replace the current natural gravity degreasing method of vertical large tank and inclined plate.

[0055] Daily processing capacity 20000m 3 / d's oilfield sewage treatment station. The volume of the large tank that separates and removes oil by natural gravity is 5000m 3 Two buildings, covering an area of 4545.5m 2 ×2 is 909m 2 , so that the crude oil content of incoming water is 750mg / L, and the oil content after treatment is reduced to 30-50mg / L. Under the same treatment capacity, the air flotation method is used to remove oil, and the induced air flotation method is adopted. The equipment is the YTF induced air flotation machine produced by Yangzhou Chenglu Environmental Engineering Co., Ltd. The equipment uses air stirring to drive water and air flotation. No need to add air flotation agent, the volume of the device is 100m 3 ×2 is 200m 3 , covers an area of 20m 2 ×2 is 40m 2 , After air flotation and oil...

Embodiment 2

[0057] The method of adding ion modifier is used to remove harmful components in oilfield sewage, which not only alleviates the metal corrosion of the water injection system, but also ensures the compliance rate of the injection water quality, and improves the compatibility of the treated sewage and the reservoir water.

[0058] The metal corrosion rate of sewage to tanks, pipes, pumps and wells is 0.5-1mm / a, which is 6.5-13 times higher than the national standard of 0.076mm / a. The PH value of the injected water is slightly acidic and the formation is not compatible, resulting in clogging of the oil layer; the treated sewage is mixed and the particle diameter exceeds the standard.

[0059] Modification of oilfield sewage by adding ion modifier:

[0060] Process operation: After degreasing the sewage, add the compound alkali before entering the mixer, so that the concentration of the compound alkali in the water is 300-500mg / L, and the compound alkali is composed of NaOH and Ca...

Embodiment 3

[0063] Before entering the settling tank, in addition to adding flocculant, iron powder is also added. The particle size of iron powder is 40-500nm, so that the concentration of iron powder in the water is 70-100mg / L, so that the agglomerated suspended solids and mechanical impurities are mixed into Iron powder increases the quality of the agglomerates and greatly speeds up the settling speed. After practical application in the oil field, the daily processing capacity is 20,000m 3 The volume of the settling tank with / d capacity is only 5000m 3 One-tenth of the settling tank. The settling speed of suspended solids and impurities is shortened from 8 to 12 hours in the original process to 1 hour. Settling efficiency increased by 7-13 times. This is equal to the volume of the sewage settling tank can be reduced by 7 to 13 times under the scale of processing the same amount of sewage. The manufacturing cost and floor area of the device are saved.

[0064] In this method, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Ph value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com