Method of extracting and separating aralia saponin from aralia mandshrica

A technology of aralia saponin and aralia aralia, which is applied in the field of preparation of aralia saponin, can solve the problems of high impurities in the extract and low yield, and achieve the effect of high content, high yield, and favorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

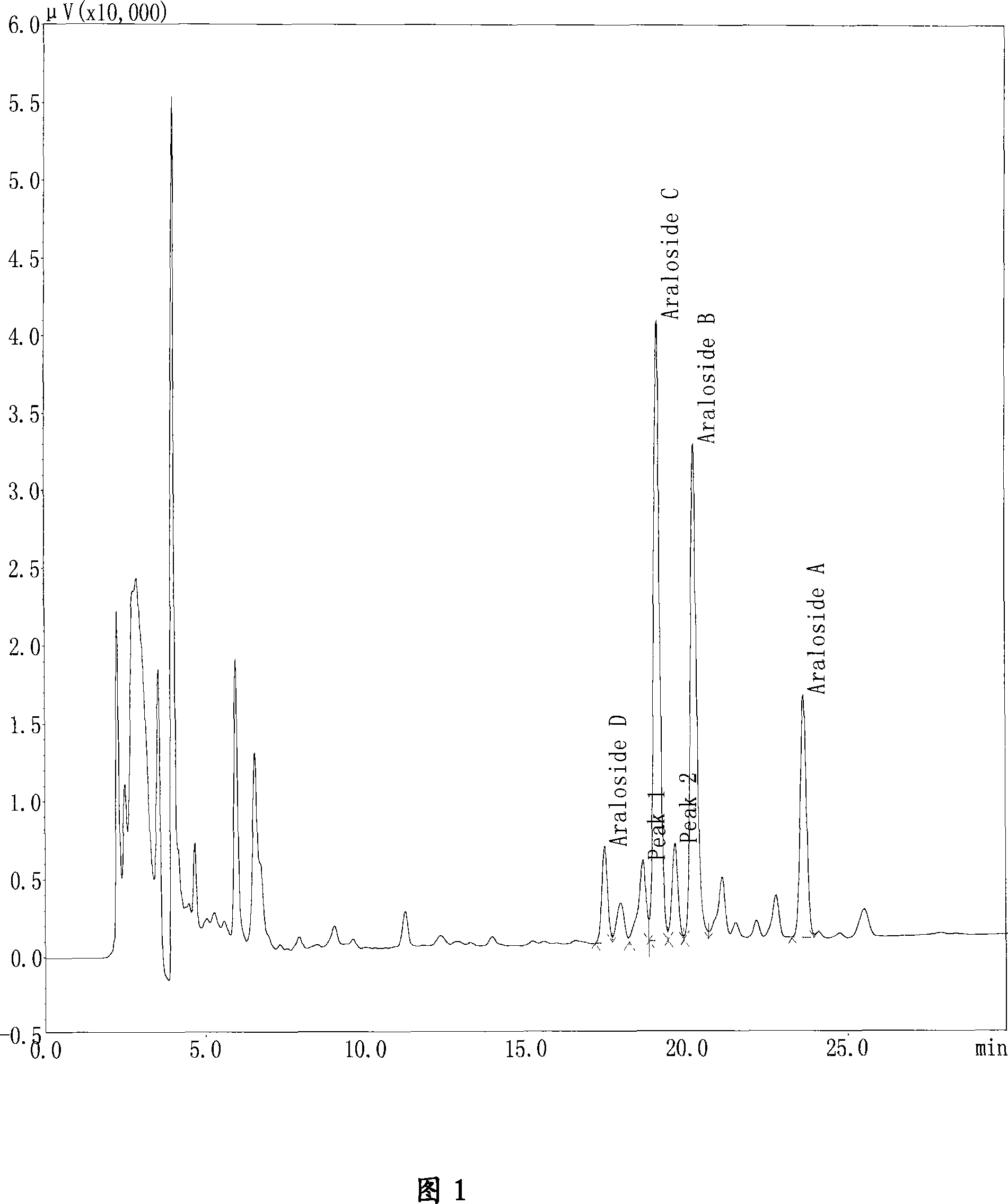

Image

Examples

Embodiment 1

[0016] (1) Raw material processing: first dry the fresh Aralia aralia, the temperature is controlled at 65-75°C or sun-dried, remove impurities, crush, and pass through a 10-40 mesh sieve;

[0017] (2) Extraction and concentration: after crushing the raw materials, use 5 times the amount of 60% ethanol to reflux and extract twice, each time for 2 hours, combine the extracts, concentrate under reduced pressure until there is no alcohol smell, and centrifuge to remove the precipitate;

[0018] (3) Column chromatography: take the precipitated supernatant and pass it through the D101 macroporous adsorption resin for adsorption, wash the resin with purified water until it is colorless, and elute with 60% ethanol until the effluent is colorless, collect and combine The eluate is concentrated under reduced pressure, ethanol is recovered, and then purified by neutral alumina resin, eluted with purified water, and the eluate is collected until complete;

[0019] (4) Drying: Concentrate...

Embodiment 2

[0021] (1) Raw material processing: directly pulverize the dried Aralia japonica after removing impurities, and pass through a 10-40 mesh sieve;

[0022] (2) Extraction and concentration: after crushing the raw materials, use 6 times the amount of 65% ethanol to reflux to extract twice, each time for 2 hours, combine the extracts, concentrate under reduced pressure until there is no alcohol smell, and centrifuge to remove the precipitate;

[0023] (3) Column chromatography: take the precipitated supernatant and pass it through HP20 macroporous adsorption resin for adsorption, wash the resin with purified water until it is colorless, and elute with 60% ethanol until the effluent is colorless, collect and combine The eluate is concentrated under reduced pressure, ethanol is recovered, and then purified by neutral alumina resin, eluted with purified water, and the eluate is collected until complete;

[0024] (4) Drying: Concentrate the eluent into a thick paste (13-18 pomi), then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com