Organic encapsulant compositions for protection of electronic components

An encapsulant and composition technology, which is applied in the direction of electrical components, printed electrical components, fixed capacitor shells/packages, etc., can solve problems such as accelerated life tests of damaged capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The encapsulant composition is prepared according to the following composition and steps:

[0077] Material Weight %

[0078] Epoxy-PNB 23.37 predissolved in dibutyl carbitol at 50.0% solids

[0079] ESD-1819 predissolved in dibutyl carbitol at 50.0% solids 23.37

[0080] N, N-dimethylbenzyl ammonium acetate 0.47

[0081] Titanium dioxide powder 31.67

[0082] Aluminum oxide powder 21.12

[0083] The mixture was roll milled 3 times at 0, 50, 100, 200, 250 and 300 psi with a 1 mil gap to give a well dispersed slurry.

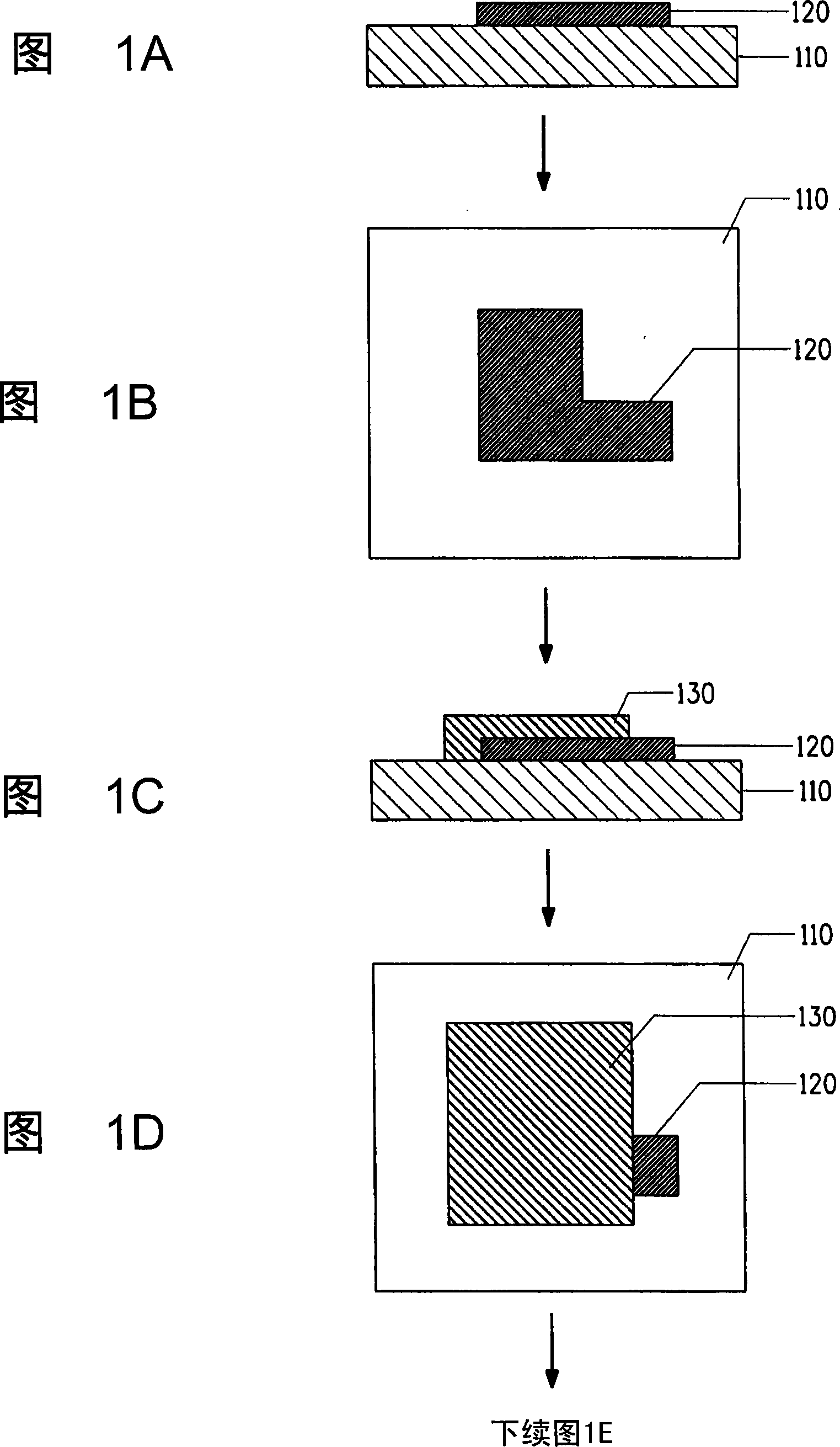

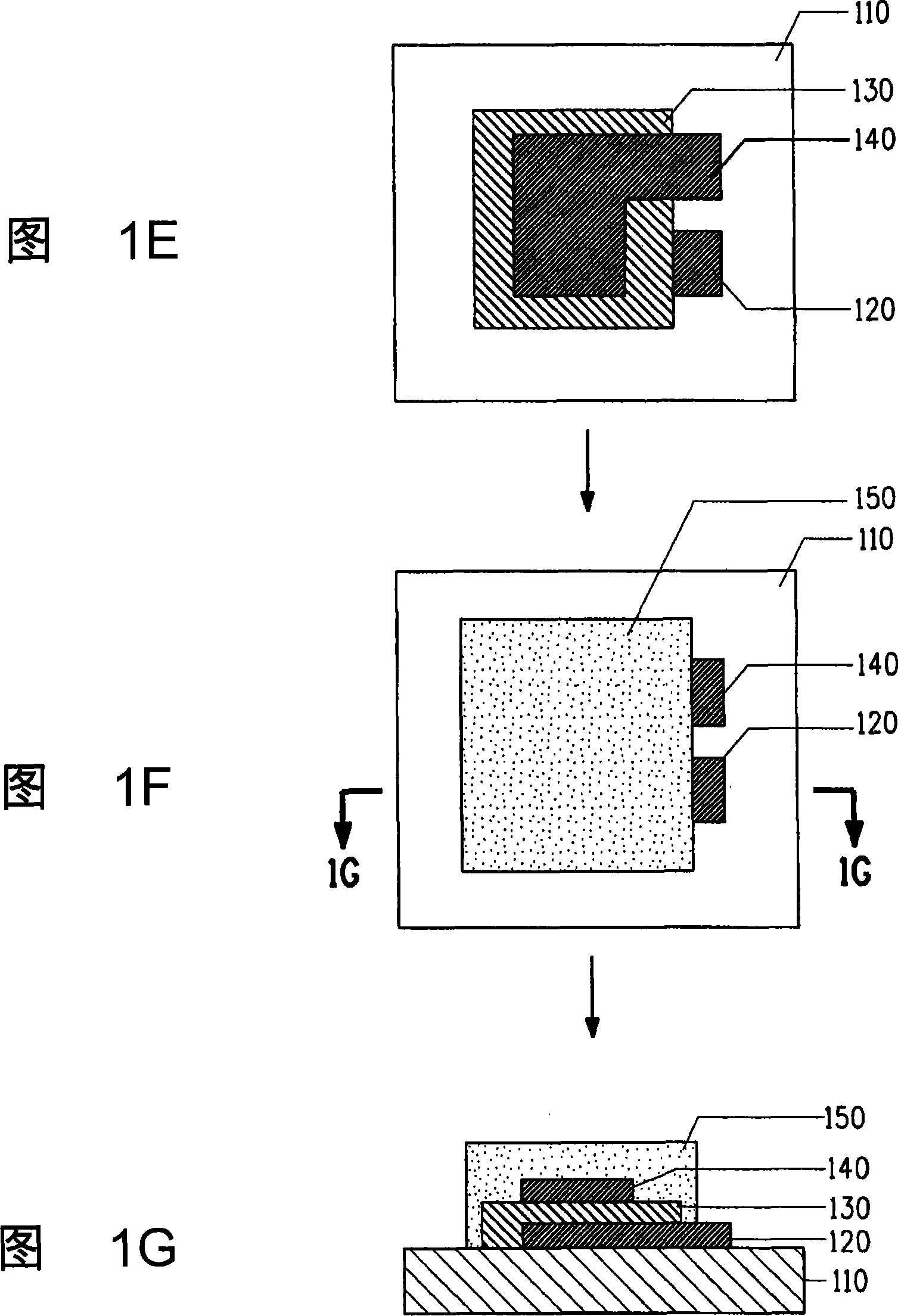

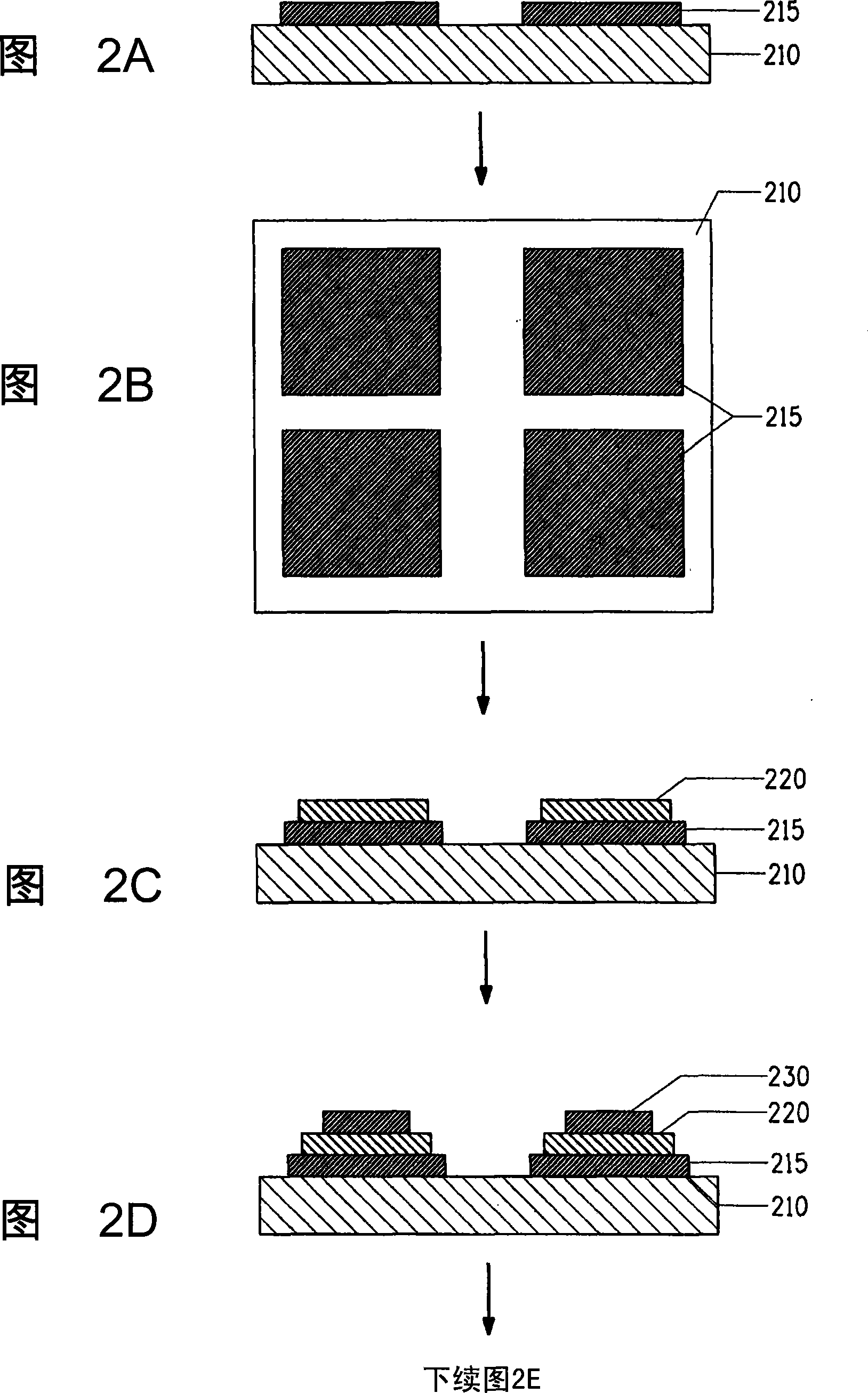

[0084]Capacitors on a commercially available 96% alumina substrate were covered with the encapsulant composition and used as test supports to determine the resistance of the encapsulant to selected chemicals. The test vectors described above were prepared as follows, which are schematically depicted in Figures 1A-1G.

[0085] As shown in FIG. 1A , an electrode material (EP320 from E.I. Nemours DuPont) was screen printed on an alumina substrate to for...

Embodiment 2

[0092] The encapsulant composition was prepared with the following components and methods:

[0093] Preparation of epoxy media

[0094] components

[0095] Terpineol 300g

[0096] Avatrel 2390 Epoxy Resin (AV2390) 200g

[0097] A 1 liter resin kettle was equipped with a heating mantle, mechanical stirrer, nitrogen purge line, thermometer and addition ports. Add terpineol to the above resin pot and heat to 40°C. When the terpineol reached 40°C, the epoxy resin was added to the stirring solvent through the addition port. After the addition was complete, the powder gradually dissolved, yielding a clear, colorless solution of moderate viscosity. Complete dissolution of the polymer took about 2 hours. The medium is then cooled to room temperature and discharged from the reactor. A known amount of media was heated at 150°C for 2 hours and the resulting media was analyzed for solids content. The solids content measured in this way was 40.33%. The viscosity of this medium mea...

Embodiment 3

[0117] An encapsulant was prepared with the same composition as in Example 2, except that Cabot Cab-O-Sil TS-530 fumed silica was used instead of Degussa R7200 fumed silica. The encapsulant was prepared according to the method described in Example 2.

[0118] The encapsulant was printed and cured as described in Example 2 on capacitors fabricated on alumina substrates. After packaging, the average capacitance of the capacitor is 39.2nF, the average dissipation factor is 1.5%, and the average insulation resistance is 2.3Gohms. The samples were then immersed in 5% sulfuric acid solution for 6 minutes at room temperature, rinsed with deionized water, and then dried at 120°C for 30 minutes. After acid treatment, the average capacitance, dissipation factor and insulation resistance were 42.3nf, 1.5%, 2.6Gohms, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com