Method of extracting matrine by ultrasound wave method

An ultrasonic method and a technology of matrine, applied in the direction of medical formula, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of low extraction rate, long extraction time, long extraction line of matrine, etc., and achieve improved The effect of extraction rate, shortening extraction time, and high practical promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

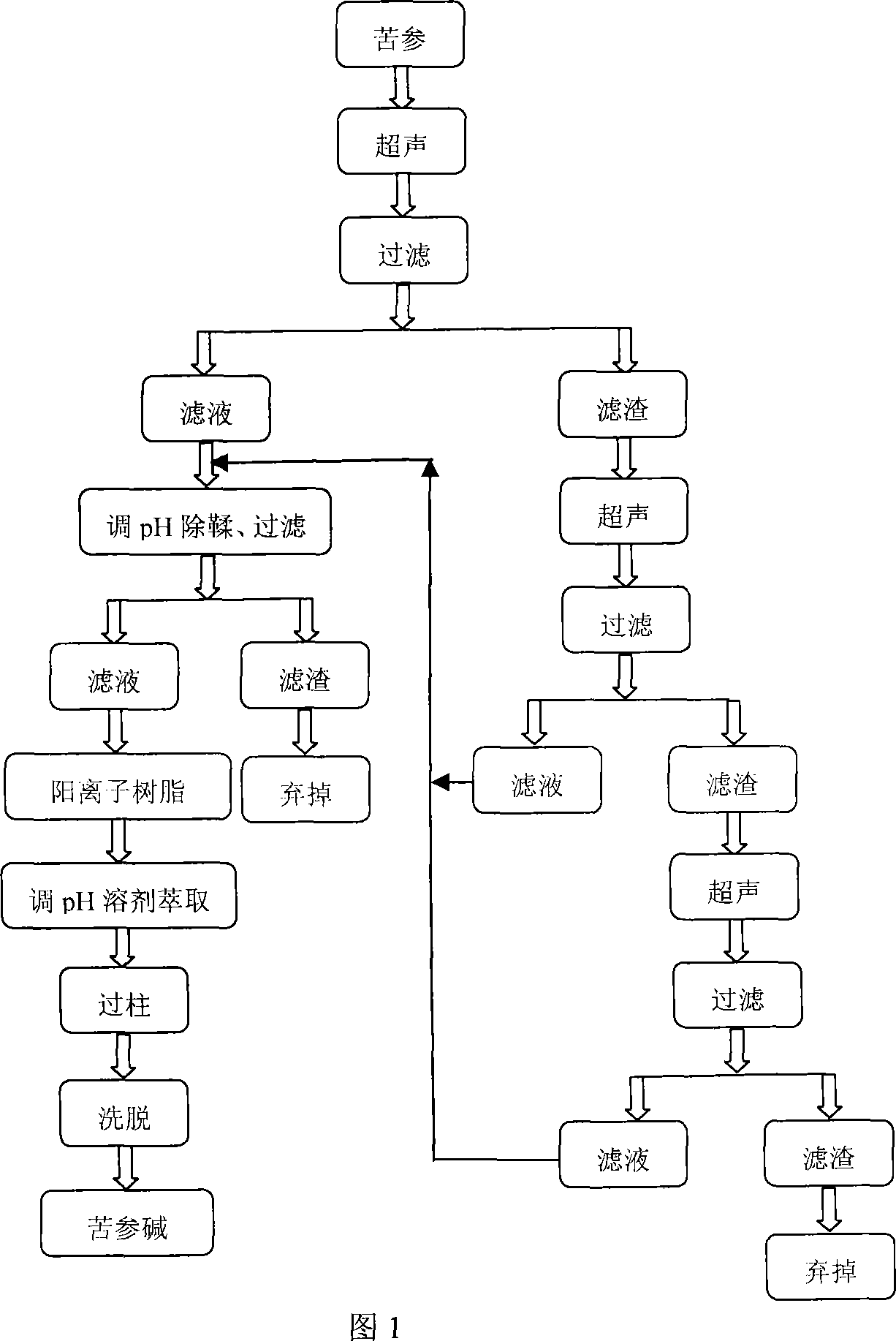

Method used

Image

Examples

Embodiment approach 1

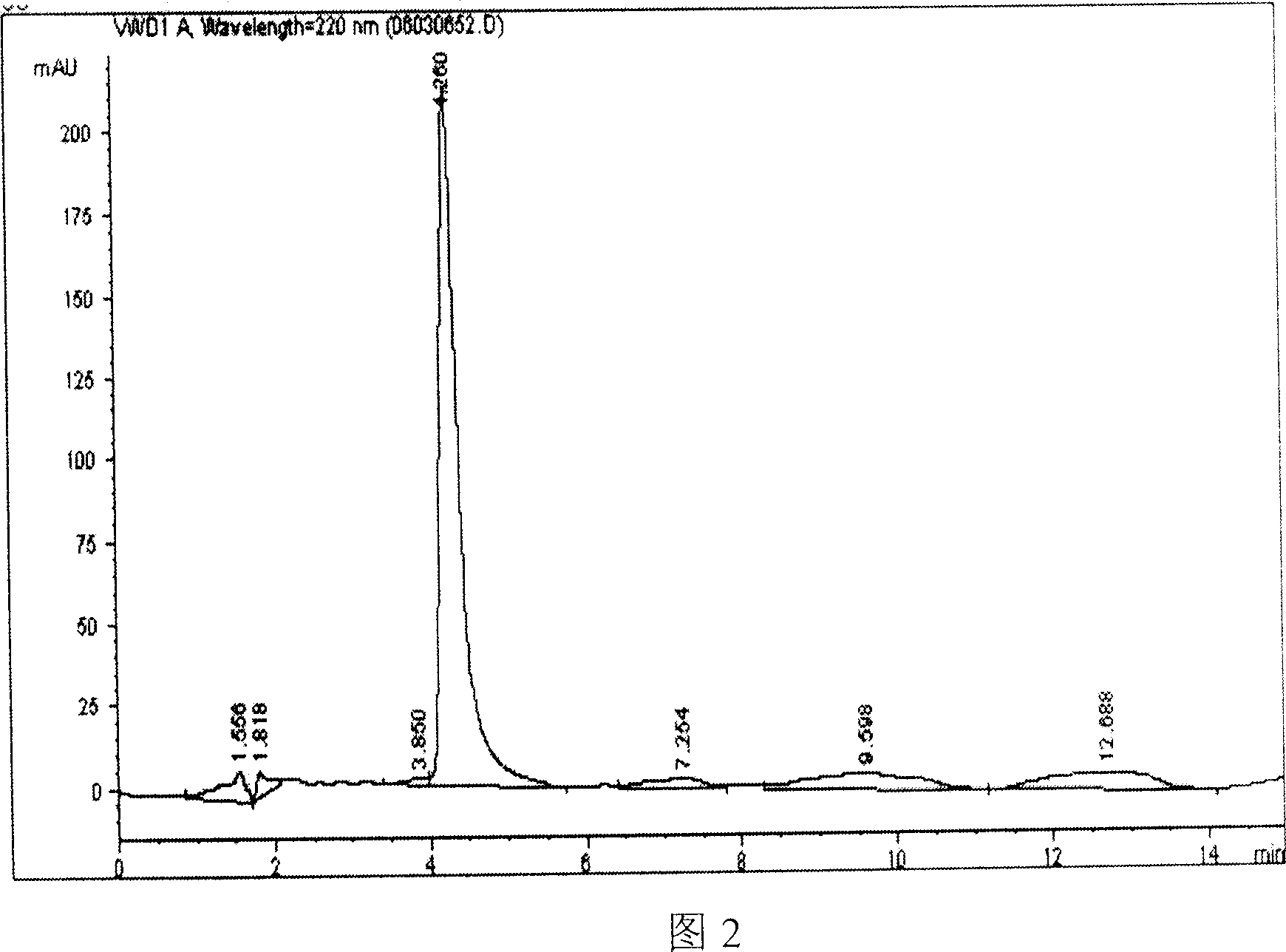

[0027] Accurately weigh 20g of Sophora flavescens powder (through a 40 mesh sieve), use 70% ethanol as solvent, the solid-liquid ratio of Sophora flavescens powder and solvent (solvent volume ml / massage of flavescens powder mass g) is 7, and the ultrasonic power is controlled at 300~ 700W ultrasonic extraction for 40min, with detection conditions as chromatographic column model: C 18 column; detection wavelength: 220nm; mobile phase: methanol: water: triethylamine (71.80: 27.85: 0.35); flow rate: 1.0ml / min; The comparison of extraction rates of matrine in the Pharmacopoeia is shown in Table 2. Add acid to remove tanning and adjust the pH to 3. After cationic resin, silica gel, Al 2 o 3 Exchange, elute with chloroform:methanol ratio of 9:1, concentrate, and recrystallize to obtain pure matrine, the purity of which is greater than 98% by liquid chromatography. See Figure 2 for the liquid chromatogram.

[0028] Ultrasonic frequency (W)

Embodiment approach 2

[0030] Accurately weigh 20g of Sophora flavescens powder (pass through a 40 mesh sieve), use 70% ethanol as solvent respectively, control the ultrasonic power at 600W, and the solid-liquid ratio of Sophora flavescens powder and solvent (solvent volume ml / matrix flavescens powder mass g) is 5 ~13 Ultrasonic extraction for 40min, with detection conditions as chromatographic column model: C 18 column; detection wavelength: 220nm; mobile phase: methanol: water: triethylamine (71.80: 27.85: 0.35); flow rate: 1.0ml / min; The comparison of extraction rates of matrine in the Pharmacopoeia is shown in Table 3. Add acid to remove tanning and adjust the pH to 3. After cationic resin, silica gel, Al 2 o 3Exchange, elute with chloroform:methanol ratio of 9:1, concentrate, and recrystallize to obtain pure matrine, the purity of which is greater than 98% by liquid chromatography.

[0031] Ratio of solid to liquid (ml / g)

Embodiment approach 3

[0033] Accurately weigh 20g of Sophora flavescens powder (through a 40-mesh sieve), set the solid-liquid ratio of Sophora flavescens powder to solvent (volume of solvent in ml / mass of flavescens powder in g) as 11, control the ultrasonic power at 500W, and pH 2 to 6 hydrochloric acid Ultrasonic extraction of solvent for 30 minutes, with detection conditions as chromatographic column model: C 18 column; detection wavelength: 220nm; mobile phase: methanol: water: triethylamine (71.80: 27.85: 0.35); flow rate: 1.0ml / min; The comparison of extraction rates of matrine in the Pharmacopoeia is shown in Table 4. Add acid to remove tanning and adjust the pH to 3. After cationic resin, silica gel, Al 2 o 3 Exchange, elute with chloroform:methanol ratio of 9:1, concentrate, and recrystallize to obtain pure matrine, the purity of which is greater than 98% by liquid chromatography.

[0034] pH of HCl

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com