Polyvinyl acetate grafted copolymer and its free radical/positive ion converting polymerization process

A technology of polyvinyl acetate and graft copolymer, which is applied in the field of graft copolymer and its preparation, can solve the problems of limitation, difficulty in the position and number of active points, difficulty in regulating and controlling the structure of the graft polymer, etc. Easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

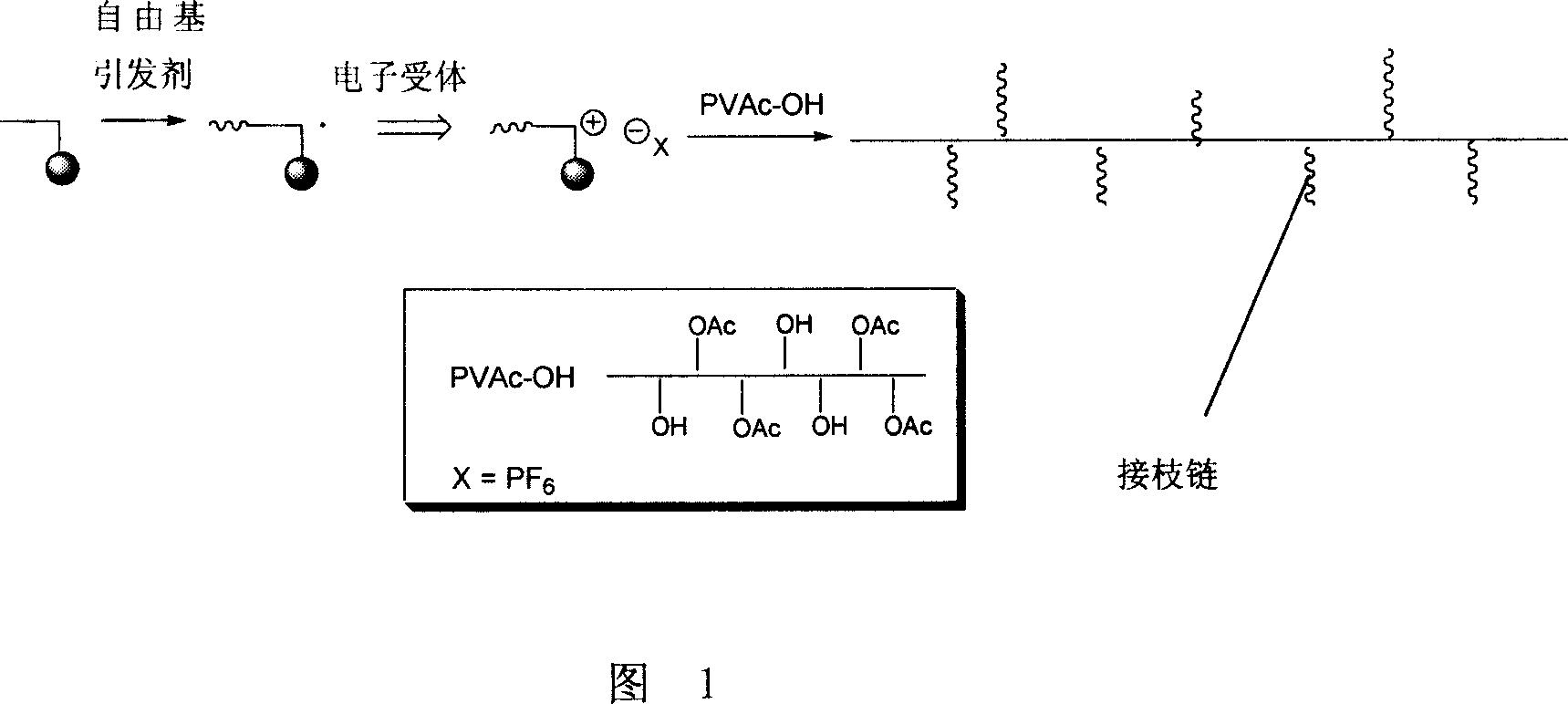

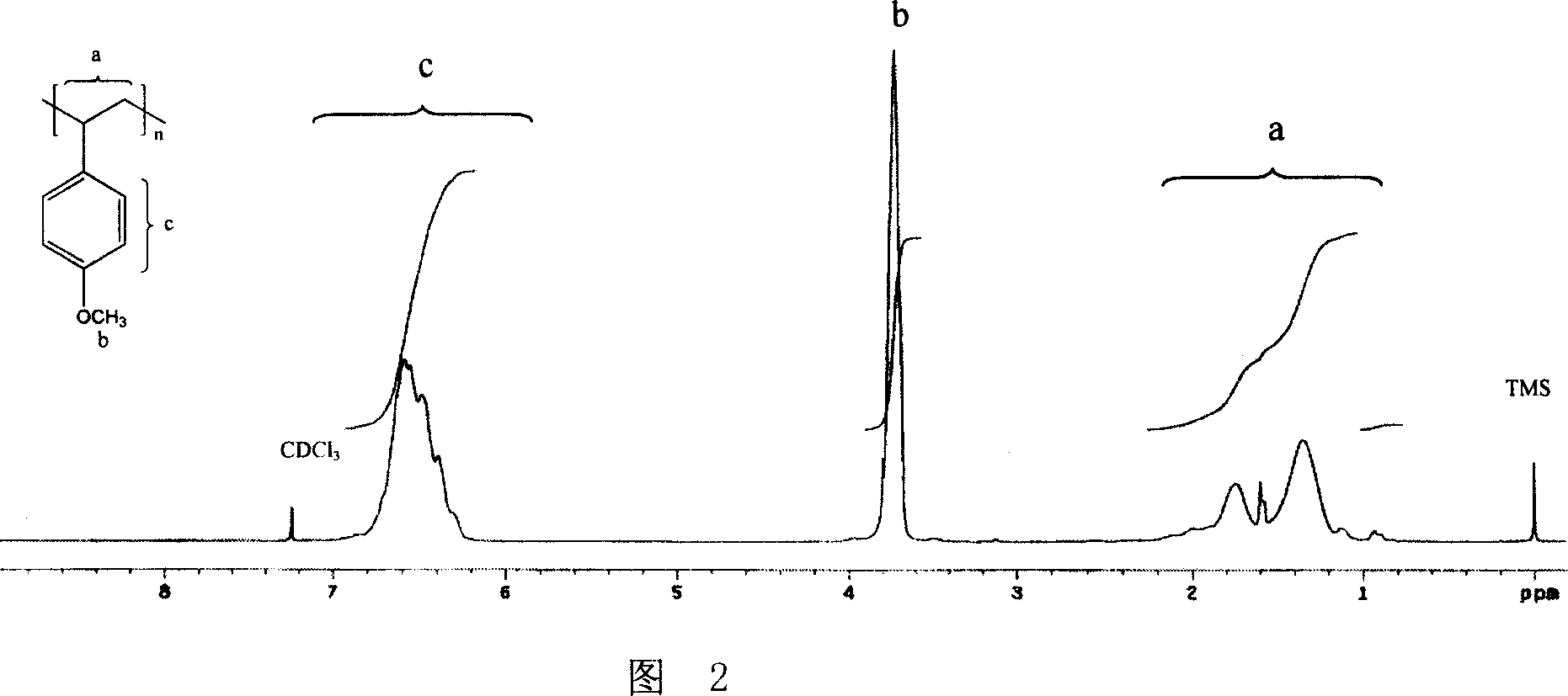

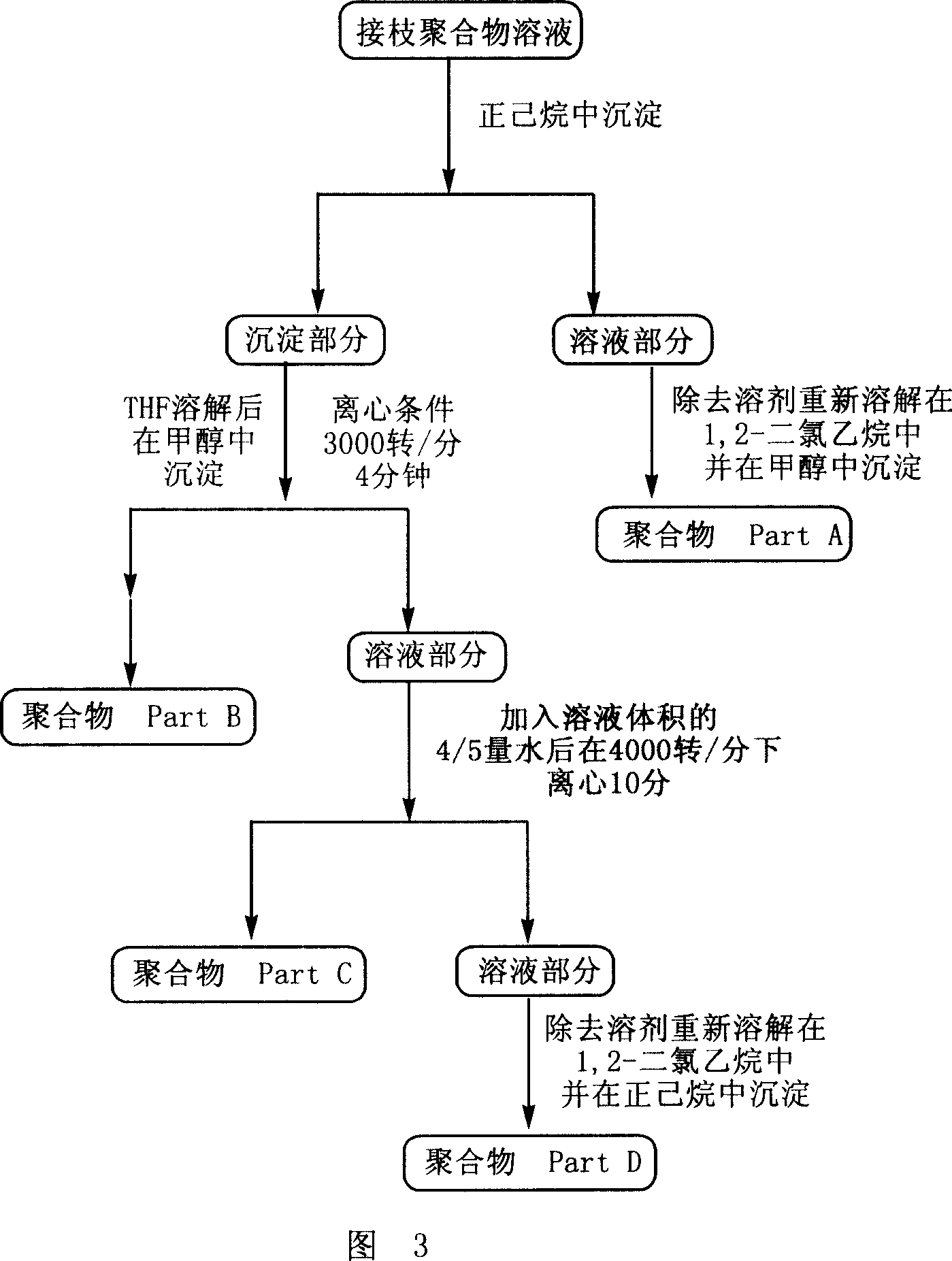

[0049] The synthesis of embodiment 1 MOS / CHO / PVAc-OH system graft polymer

[0050] 1. Raw materials

[0051] MOS: p-methoxystyrene (CH 2 = CHC 6 h 4 OCH 3 )

[0052] CHO: cyclohexene oxide (C 6 h 10 O)

[0053] AIBN: azobisisobutyronitrile, free radical initiator

[0054] Ph 2 IPF 6 : Diphenyliodohexafluorophosphate, electron acceptor

[0055] PVAc-OH: Partially hydrolyzed polyvinyl acetate

[0056] (the degree of polymerization is 220, Mn=1.9×10 4 , the hydroxyl content is 16%, Kuraray Corporation)

[0057] 2. Graft polymerization reaction

[0058] Add all the monomers, free radical initiators and electron acceptors into the polymerization tube according to the proportions in Table 1, and seal the tube after degassing with liquid nitrogen vacuum circulation for several times on the vacuum line (or after 10 minutes of nitrogen gas), Polymerization was then carried out at a temperature of 80° C. for four hours.

[0059] Numbering

MOS

/ M

...

Embodiment 2

[0070] Embodiment 2 The control (adjusting the ratio of MOS / CHO and PVAc-OH) of MOS / CHO / PVAc-OH system graft polymer composition

[0071]Add all the monomers, free radical initiators and electron acceptors into the polymerization tube according to the proportions in Table 4, degas the tube with liquid nitrogen on the vacuum line for several times, seal the tube, and then put it under the temperature condition of 80 ℃ Polymerize for four hours.

[0072] Numbering

MOS

/ M

CHO

/ M

AIBN

/ mM

Ph 2 IPF 6

/ mM

PVAC-OH

/ g

Yield / g

1

2

3

4

5

6

0.7

1.05

1.4

1.4

1.4

1.4

1.5

2.25

3.0

3.0

3.0

3.0

12

12

12

12

12

12

24

24

24

24

24

24

0.1

0.1

0.1

0.08

0.06

0.04

0.19

0.27

0.31

0.32

0.27

0.27

[0073] Polymerization ...

Embodiment 3

[0079] The synthesis of embodiment 3 AN / BVE / CHO / PVAc-OH system graft polymer

[0080] raw material:

[0081] AN: acrylonitrile (CH 2 =CHCN)

[0082] BVE: Vinyl butyl ether (CH 2 = CHOC 4 h 9 )

[0083] CHO: cyclohexene oxide (C 6 h 10 O)

[0084] AIBN: azobisisobutyronitrile, free radical initiator

[0085] Ph 2 IPF 6 : Diphenyliodohexafluorophosphate, electron acceptor

[0086] PVAc-OH: Partially hydrolyzed polyvinyl acetate

[0087] (the degree of polymerization is 220, Mn=1.9×10 4 , the hydroxyl content is 16%, Kuraray Corporation)

[0088] Add all the monomers, free radical initiators and electron acceptors to the self-made glass polymerization tube according to the ratio in Table 7, change the amount of different PVAc-OH on the vacuum line, degas with liquid nitrogen vacuum cycle for many times, and then seal the tube. tube, and then polymerized at 80°C for 4 hours.

[0089]

No.

AN

/ M

BVE

/ M

CHO

/ M

A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com