Method for preparing silver/silicon dixoide nucleocapsid structure nano particles

A technology of silica and core-shell structure, applied in the direction of coating, etc., to achieve the effect of simple process, safe operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

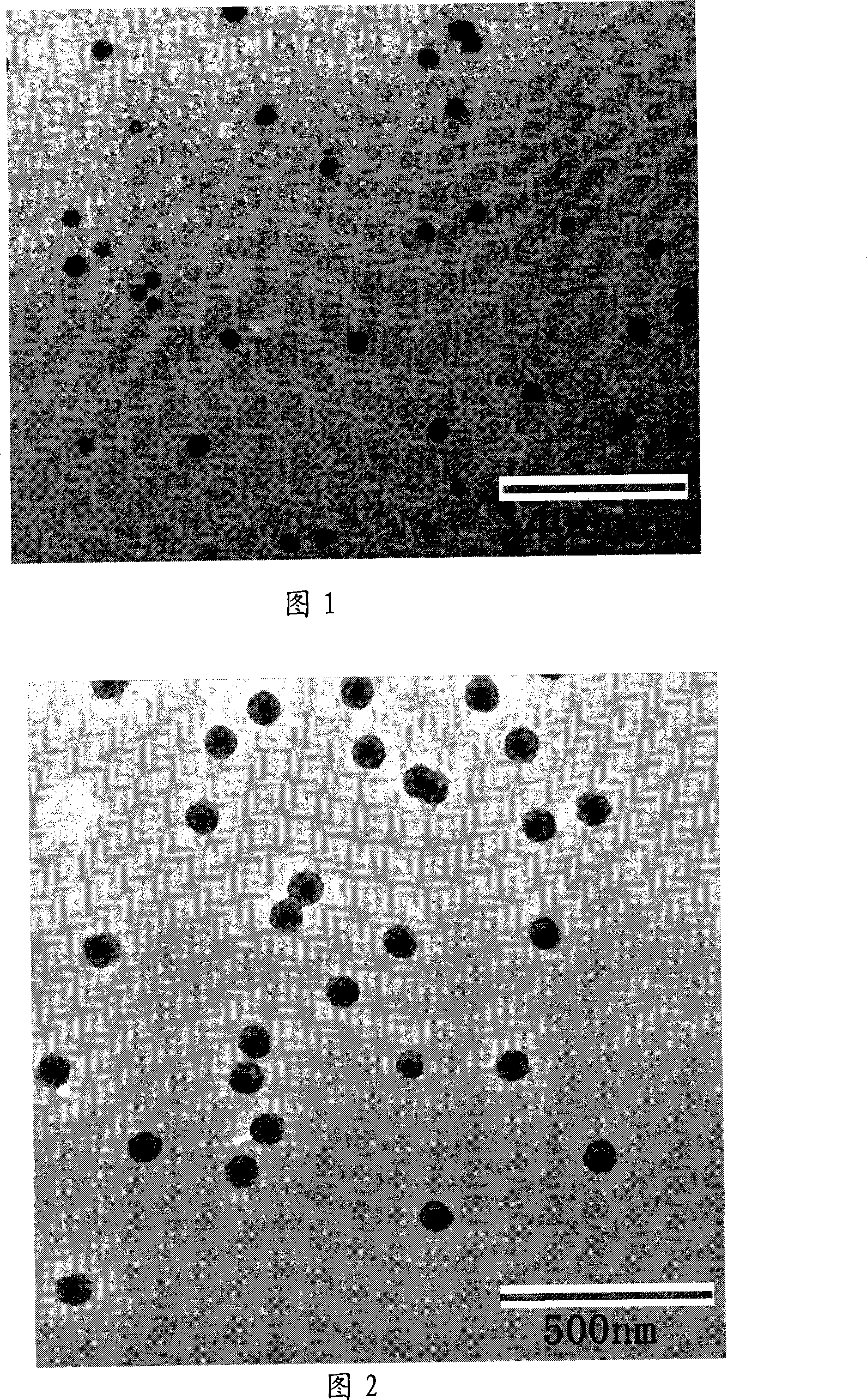

[0031] 0.4mmolg hexadecyltrimethylammonium bromide is dissolved in 180ml water, add silver nitrate, make the concentration of silver nitrate in the whole solution be 2.5mmol / L, after stirring for 1 minute, ascorbic acid (0.417mmol) after 20ml water dissolving Slowly and uniformly add to the mixture, adjust the pH value to 6 with sodium hydroxide solution, react for 10 minutes, add 50ml of ethanol, dropwise add 0.5ml of tetraethyl orthosilicate, continue to stir for 3 hours and then let stand. Observed by electron microscope, as shown in Figure 1, the product particles are uniform, the concentration is 200ppm, and the average particle diameter is 56nm, as shown in Figure 7.

Embodiment 2

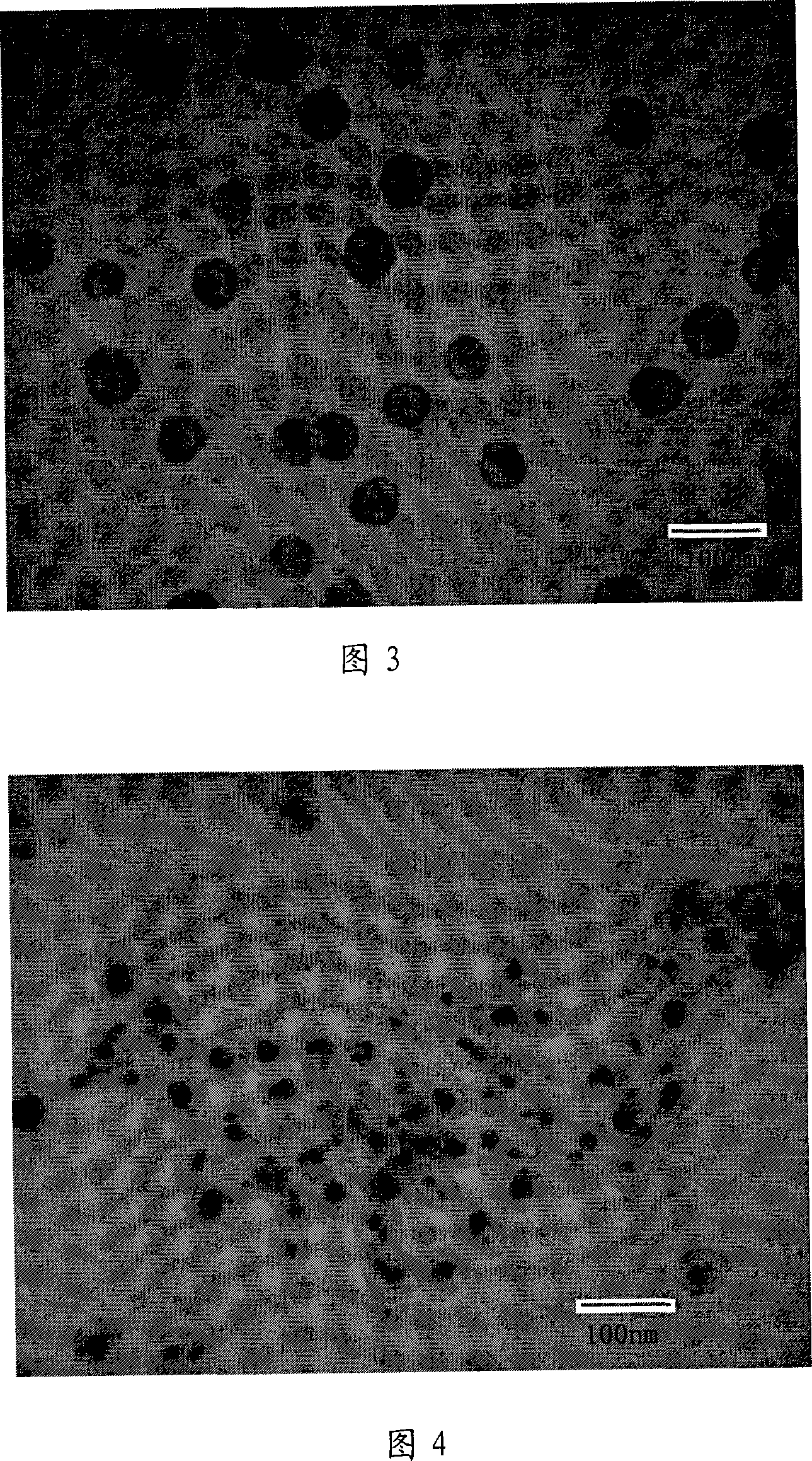

[0033] Dissolve 0.8mmol cetyltrimethylammonium bromide in 180ml of water, add silver nitrate, make the concentration of silver nitrate in the whole solution be 5mmol / L, after stirring for 1 minute, slowly and uniformly dissolve 20ml of water-soluble ascorbic acid (0.83mmol) was added into the mixture, and the pH value was adjusted to 8 with sodium hydroxide solution. After reacting for 10 minutes, 50 ml of ethanol was added, 1 ml of ethyl orthosilicate was added dropwise, and the mixture was left to stand after stirring for 3 hours. After changing the amount of surfactant and the concentration of silver nitrate, observed by electron microscope, as shown in Figure 2, the dispersion has not decreased significantly, the product particles are uniform, the concentration is 400ppm, the silver core of about 16-22nm and the whole The average particle size of the particles is about 50nm.

Embodiment 3

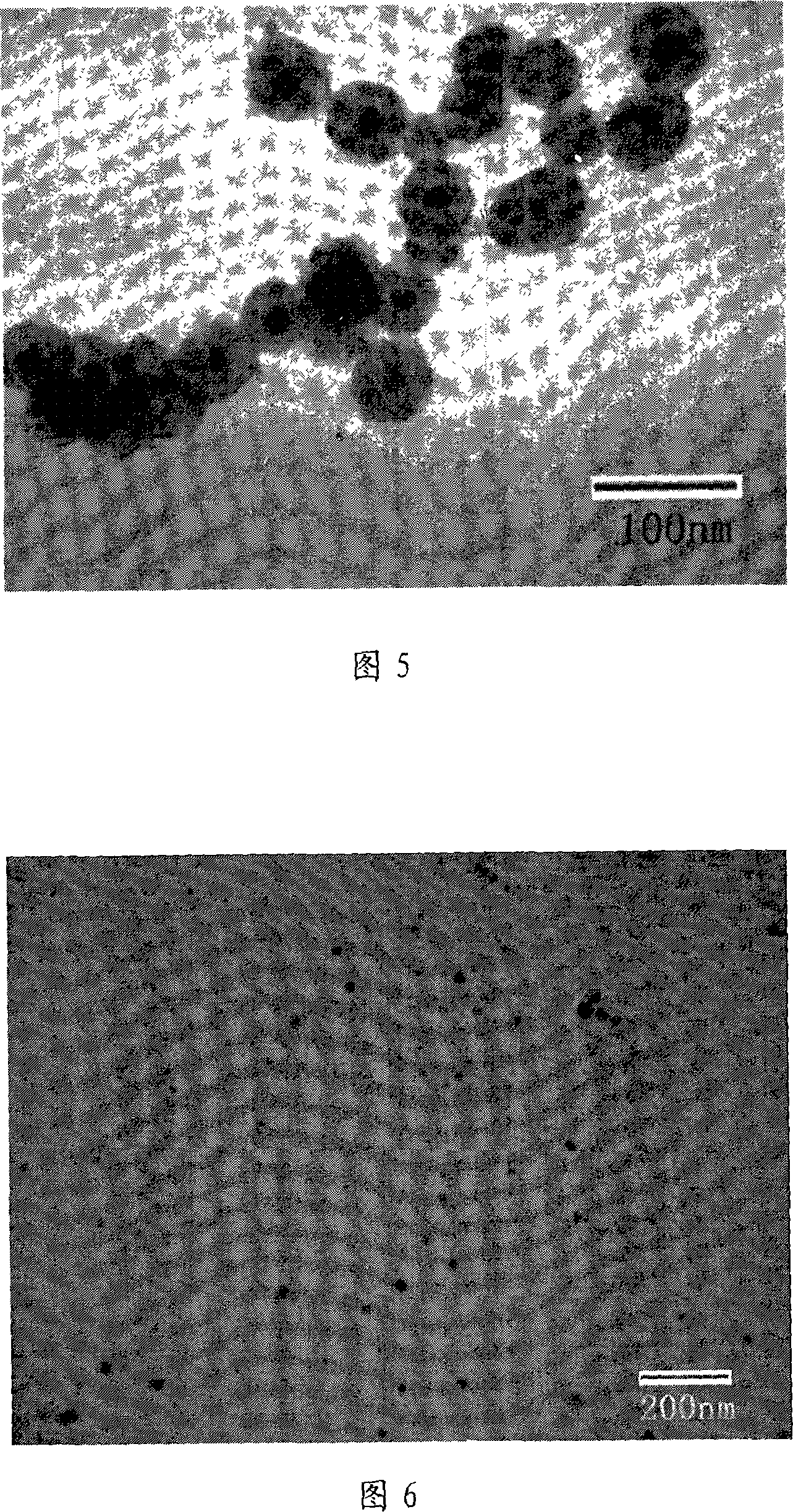

[0035] Drop 2.5ml of hydrazine hydrate (0.1mol / L) into the aqueous solution containing 0.2mmol of hexadecyltrimethylammonium bromide, stir for 2 minutes, then drop into the silver nitrate solution at a constant speed to make the silver nitrate concentration in the whole solution 1.25mmol / L, continue to stir for 7 minutes, add 2ml of ammonia water and 50ml of ethanol solution, the pH value is 10, continue to react for 1 minute, then add 0.25ml of ethyl orthosilicate. Stirring was continued for 2 hours and then left to stand. Observed by electron microscope, as shown in Figure 3, the particles have good dispersion and uniform particle size, the concentration is 100ppm, the silver core size is between 6-12nm, and the particle size is between 35-50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com