Transparent electrode and its manufacturing method

A technology for transparent electrodes and manufacturing methods, applied in electrode system manufacturing, cold cathode manufacturing, cable/conductor manufacturing, etc., can solve the problems of lack of durability, difficult to etch, and increased crystallinity of the surface of transparent conductive films, and achieves heat and humidity resistance. Excellent performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, the present invention will be further specifically described through examples.

[0101] [Production of sputtering target and substrate with transparent conductive film]

manufacture example 1

[0103] (1) Production of sputtering target

[0104] Zinc oxide powder (manufactured by Shirasui Tec Co., Ltd.) with an average particle size of 1 μm or less and tin oxide powder (manufactured by Mitsubishi Materials Corporation) with an average particle size of 1 μm or less were mixed so that Zn / (Zn+Sn)=0.79 (atomic ratio) ) ratio, put it into a resin crucible, and then add pure water to use hard ZrO 2 Ball mill for wet ball mill mixing. The mixing time was 20 hours.

[0105] The resulting slurry was taken out, filtered, dried and granulated.

[0106] Apply 294MPa (3t / cm 2 ) pressure, pressurize and form with cool water pressure.

[0107] The molded body was sintered as described below.

[0108] In the sintering furnace, at every 0.1m 3 Sintering was performed at 1500° C. for 5 hours in an atmosphere in which oxygen was introduced at a rate of 5 L / min in the furnace volume. At this time, the temperature was raised to 1000°C at 1°C / min, and to 1000-1500°C at 3°C / min. Th...

manufacture example 2-7

[0121] Zinc oxide powder with an average particle size of 1 μm or less and tin oxide powder with an average particle size of 1 μm or less were used as raw material powders, and the ratio of zinc atoms to tin atoms was prepared in the ratio shown in Table 1. 1 A sputtering target (sintered compact target 2-7) was produced in the same manner, and a substrate on which a transparent conductive film was formed was produced.

[0122] In addition, the sputtering target has a diameter of 152 mm and a thickness of 5 mm.

[0123] Tables 1 and 2 show the properties of the sputtering target and the evaluation results of the transparent conductive film.

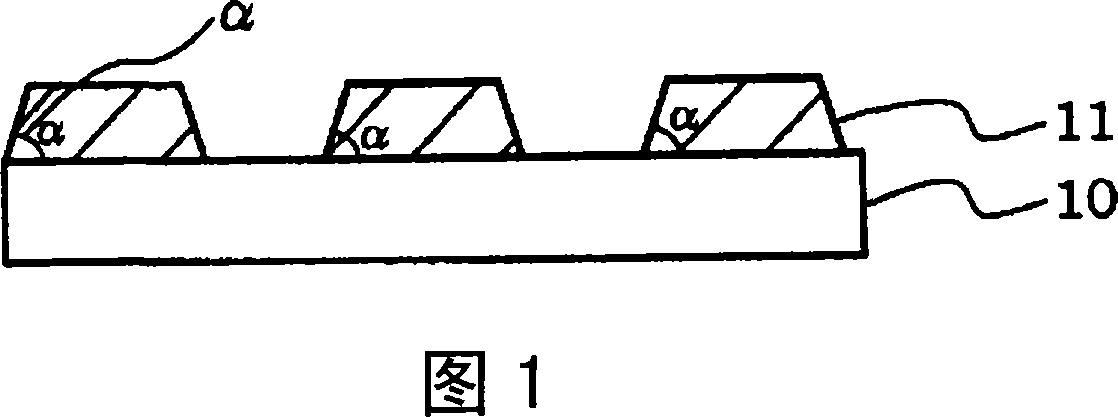

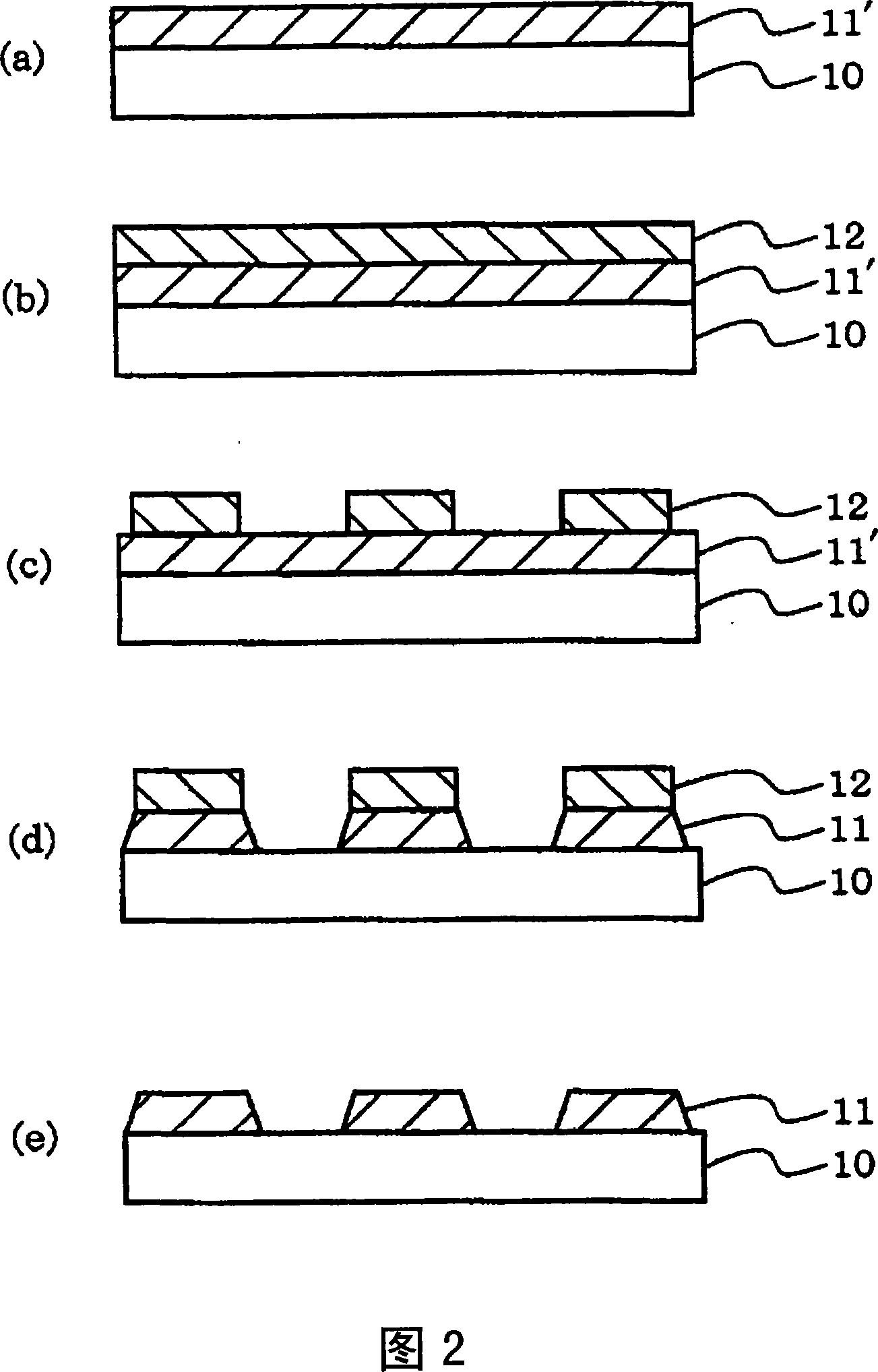

[0124] [Production of transparent electrodes]

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com