Laminate including active material layer and solid electrolyte layer, and all solid lithium secondary battery using the same

A solid electrolyte layer, lithium secondary battery technology, applied in secondary batteries, battery pack parts, electrode carriers/current collectors, etc., can solve the problems of short battery life and difficult to use active materials stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0261] In the production method of the laminate, the active material may be, for example, the first substance such as the first phosphoric acid compound. The solid electrolyte may be a second substance such as a second phosphoric acid compound.

[0262] Next, the preparation method of the all-solid lithium secondary battery of the present invention will be explained.

[0263] By forming the negative electrode active material layer on the first laminated body prepared in the above manner so as to face the positive electrode active material layer with the solid electrolyte layer interposed therebetween, it is possible to prepare a layer comprising the first laminated body and the negative electrode active material layer. An all-solid-state lithium secondary battery composed of at least one combination of the second laminate. When the all-solid lithium secondary battery includes a plurality of the above-mentioned combinations, for example, each combination is stacked with a solid ele...

Embodiment 1-1

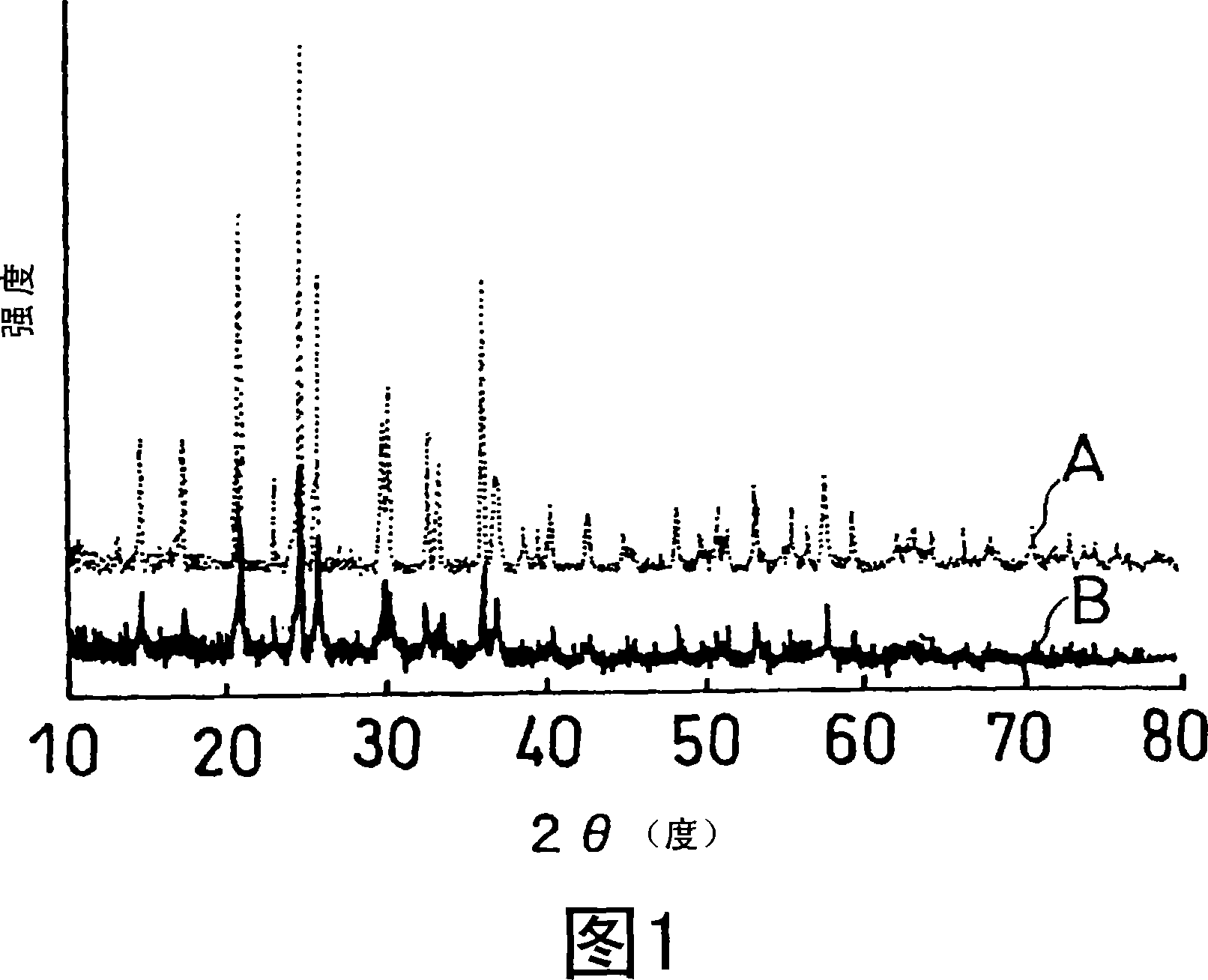

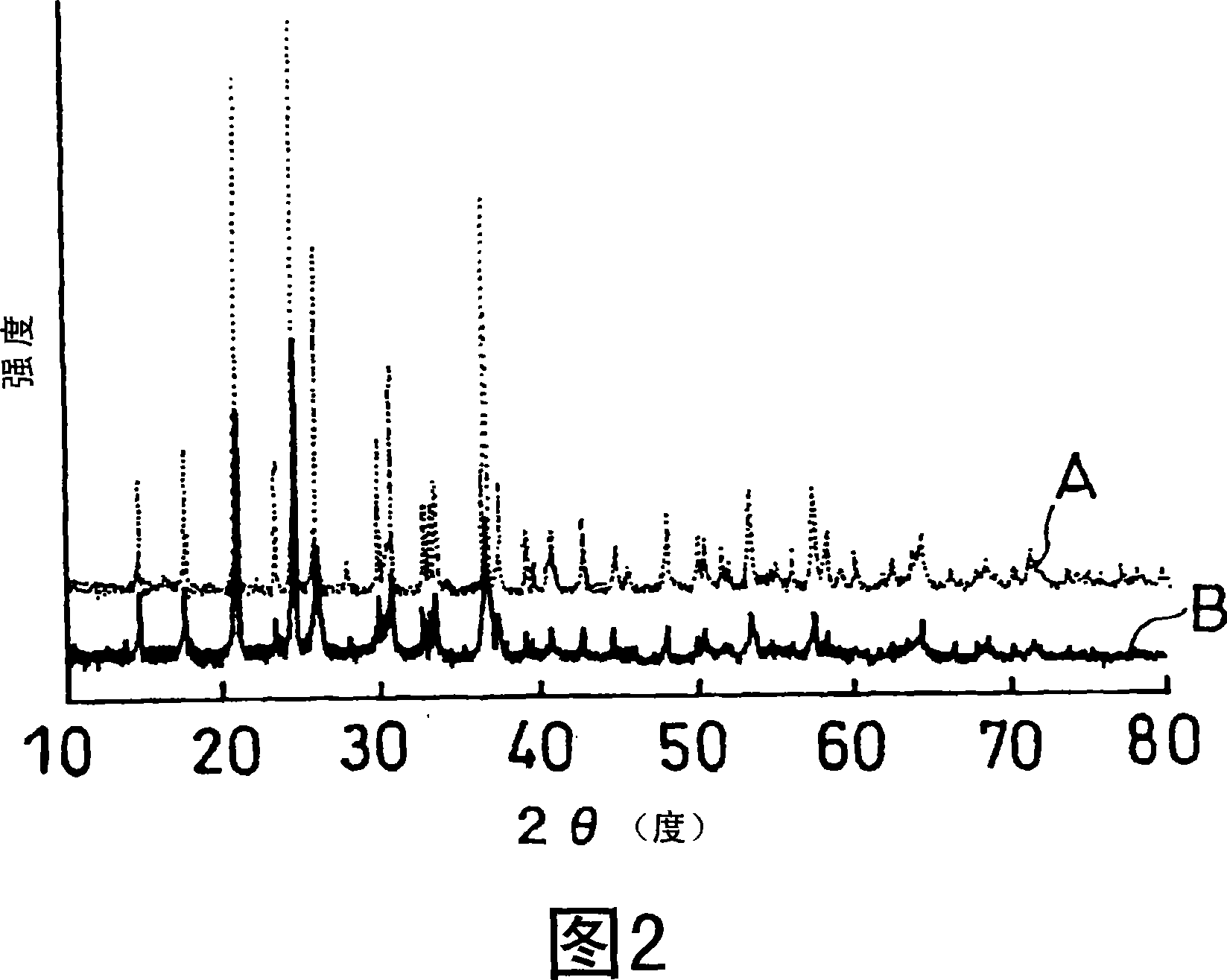

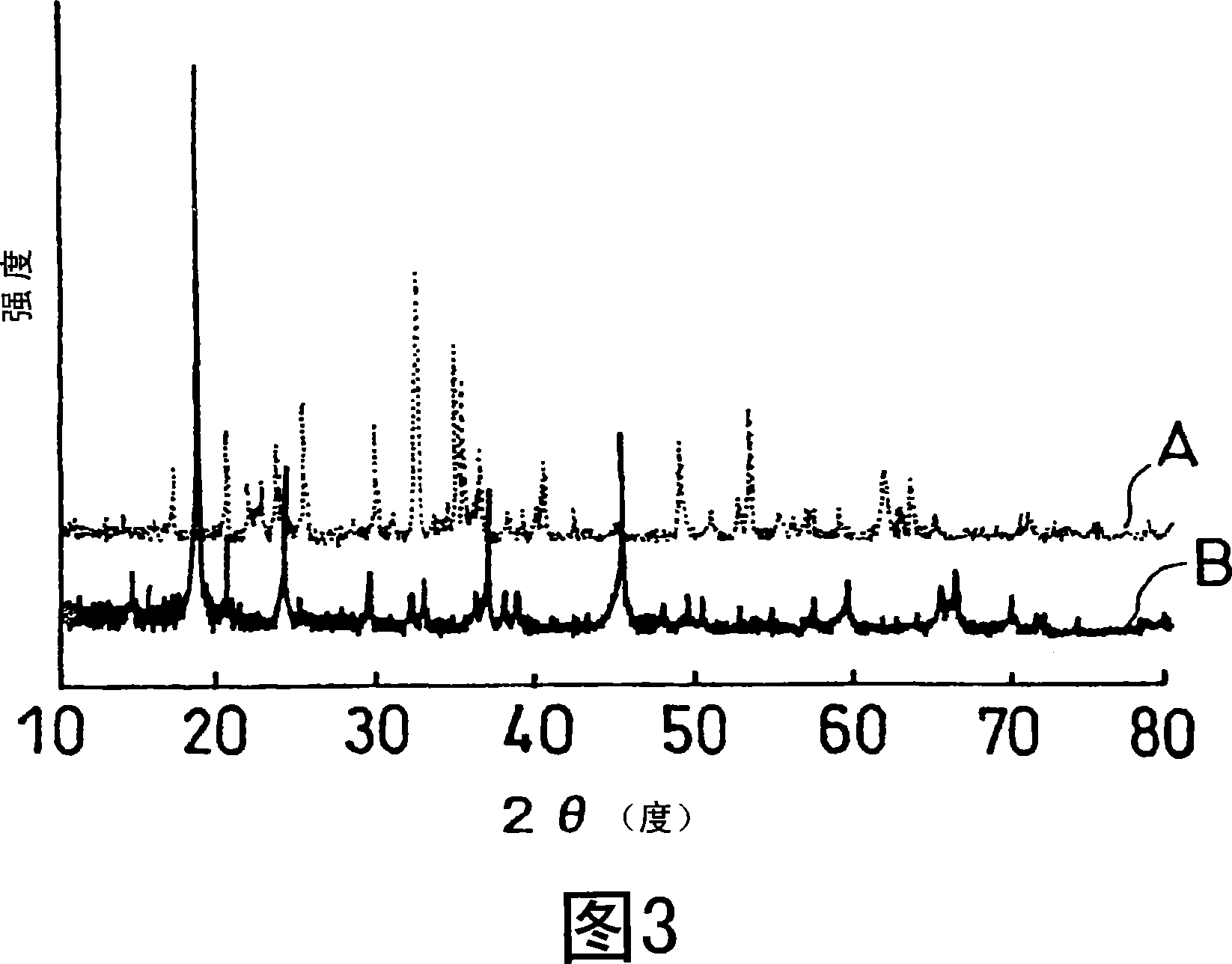

[0332] When the sintering method is used as described above to produce the first laminate or the second laminate having an electrochemically active interface between the active material and the solid electrolyte, sintering between the active material and the solid electrolyte is required during sintering No side reactions other than sintering occur at the interface. Therefore, the reactivity between the active material and the solid electrolyte when heated at 800°C was examined.

[0333] First, the reactivity between the positive electrode active material and the solid electrolyte will be explained.

[0334] (Sintered body 1)

[0335] Use LiCoPO4 As a positive electrode active material, and use Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 As a solid electrolyte. The positive electrode active material and the solid electrolyte were crushed in a ball mill to prepare a particle size of about 1 μm. These powders were mixed in a ball mill at a weight ratio of 1:1 and shaped into particles with a dia...

Embodiment 1-2

[0382] The following batteries and comparative batteries were prepared and charged and discharged under predetermined conditions to obtain their discharge capacity.

[0383] (Battery 1)

[0384] First, prepare the Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Representative solid electrolyte powder and LiCoPO 4 Representative positive electrode active material powder. The solid electrolyte powder is mixed with polyvinyl butyral resin as a binder, n-butyl acetate as a solvent, and dibutyl phthalate as a plasticizer, and zirconium dioxide balls are used in the ball mill The mixture was mixed together for 24 hours to prepare a slurry for forming a solid electrolyte layer.

[0385] A slurry for forming the positive electrode active material layer was also prepared in the same manner as the solid electrolyte layer slurry.

[0386] Subsequently, the solid electrolyte layer slurry was applied to the carrier film 1 mainly composed of polyester resin using a doctor blade. Then, the applied slurry was dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com