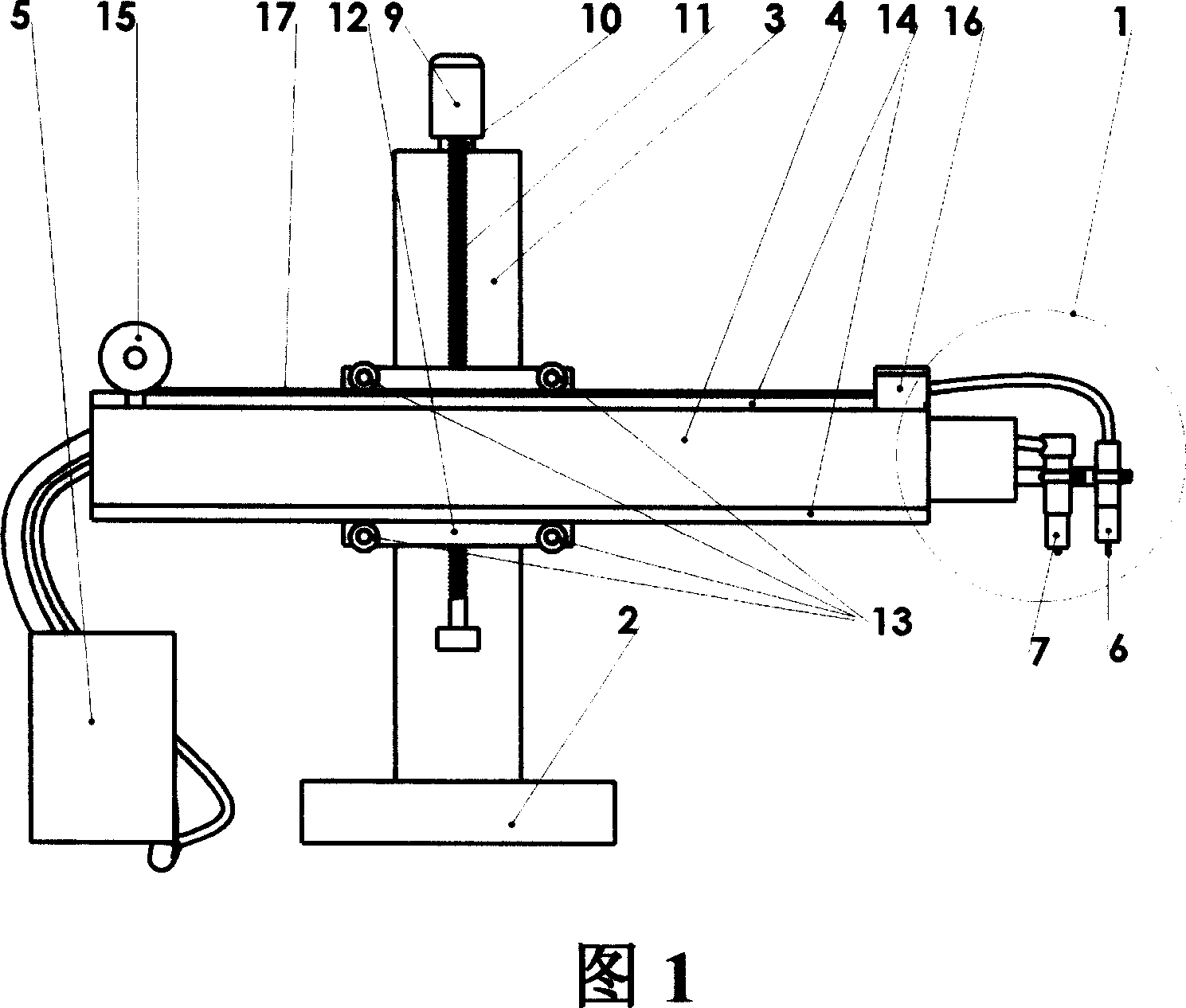

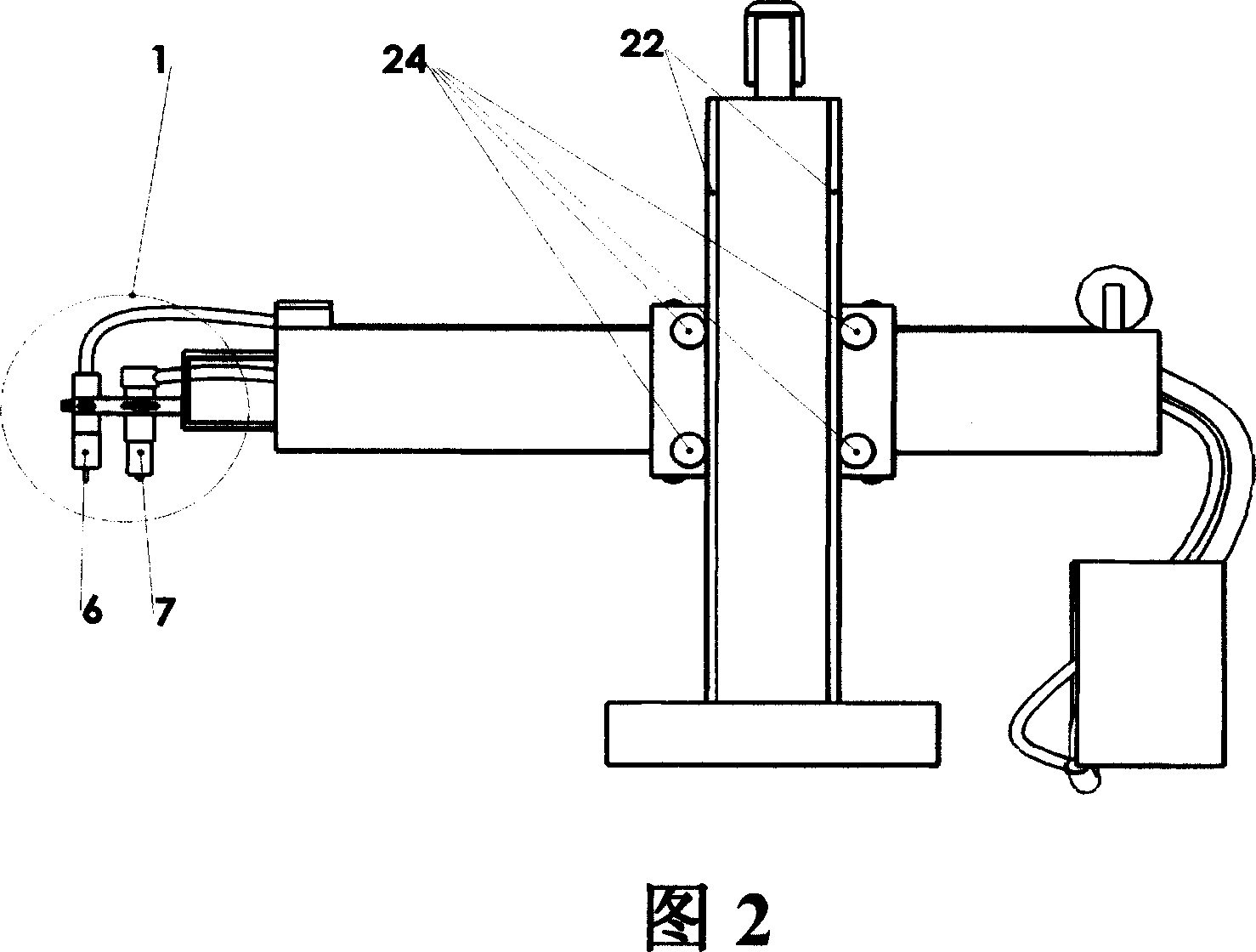

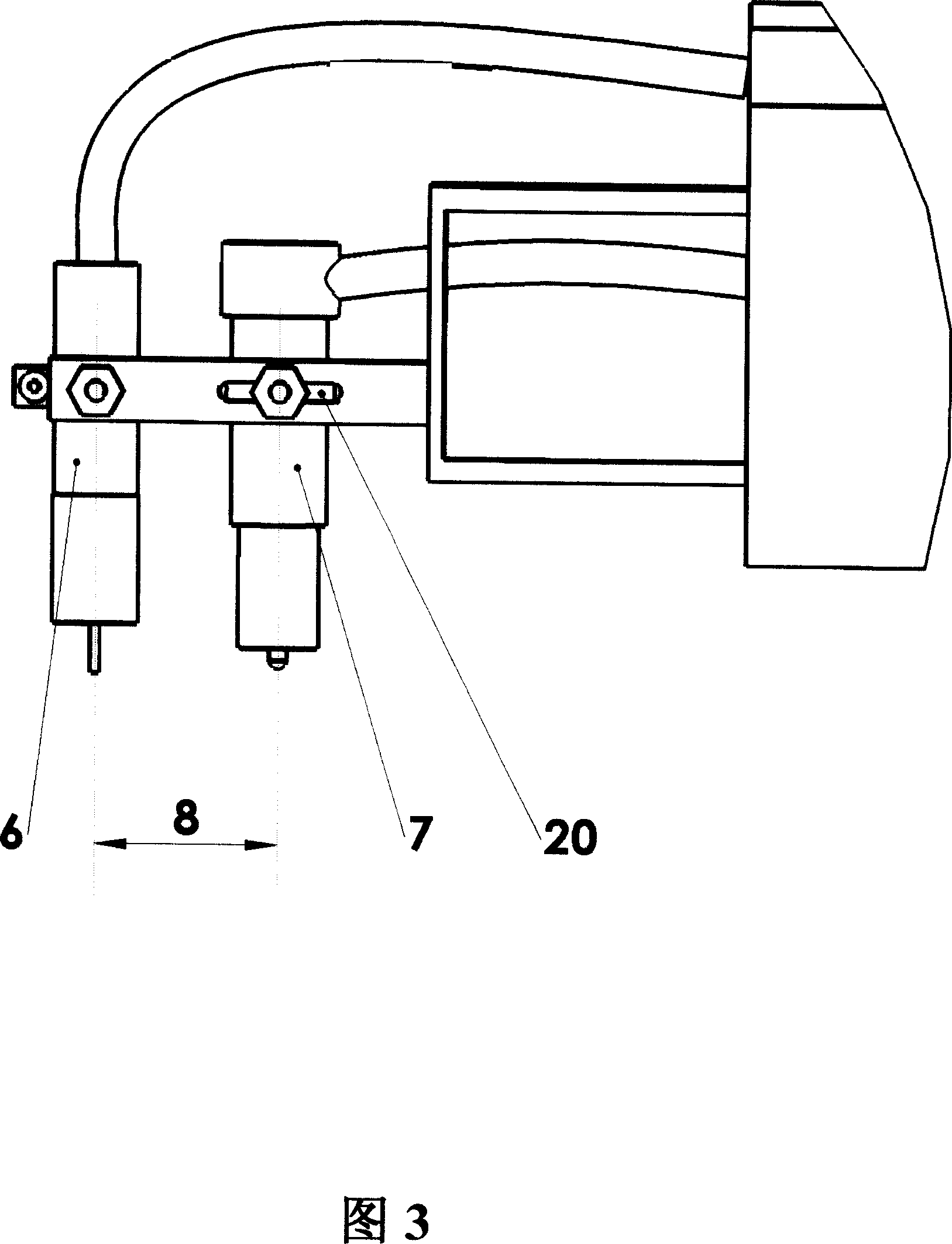

Single-side MIG and TIG synchronous automatic soldering method and device

A synchronous automatic, welding device technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of lack of synchronous remelting, low deposition speed, poor arc stability, etc., to eliminate the phenomenon of arc instability, The effect of improving weld formation and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0053] It should be noted that Fig. 5 and Fig. 6 show the schematic diagrams of the welding of the VG3 shell of the Three Gorges Project, that is, the automatic welding of the rust-proof aluminum spiral welded pipe and the aluminum alloy cast flange ring seam. The shell is required to be welded according to ABB company's drawings, and the weld seam requires X-ray flaw detection level II or above. It turned out that ABB company used plasma MIG welding. This process requires huge investment in equipment, and the welding seam is not beautiful in appearance and high in efficiency.

[0054] If the welding process method of remelting after MIG welding alone is adopted, the efficiency is low, the weld seam is poorly formed, and the welding deformation is large (it cannot meet the requirements of the drawing for circular runout).

[0055] Using the welding process of the present invention, under the condition of fully meeting the requirements of the drawings, the equipment investment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com