Flame-retardant resin composition and molded body using same

A resin composition and a flame-retardant technology, which are applied in the field of flame-retardant resin compositions and molded bodies using the same, can solve the problems of low volume intrinsic resistance value, reduced mechanical properties of flame-retardant materials, inability to obtain insulation resistance, and the like, Achieve excellent insulating properties, high flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

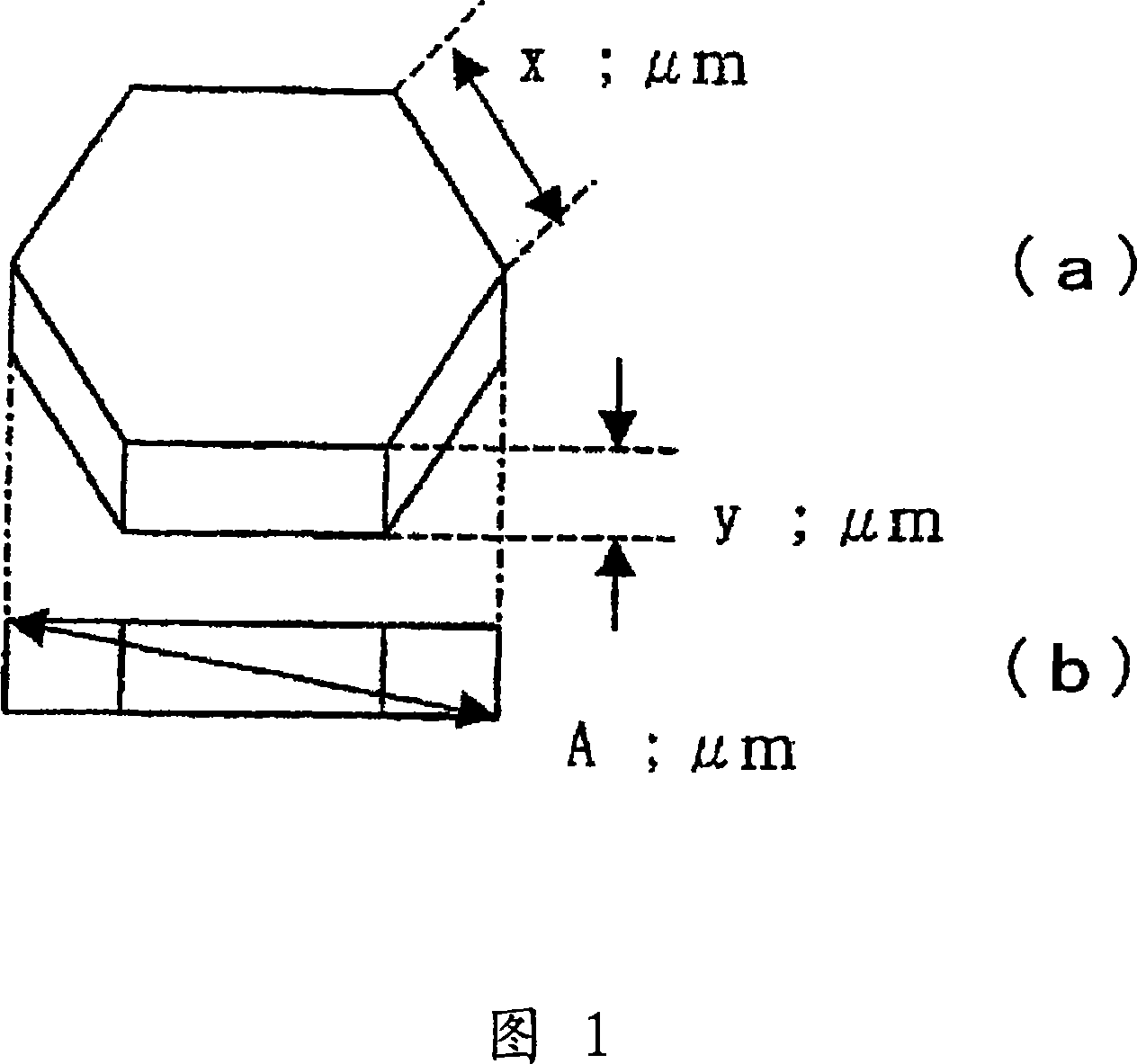

[0090] Magnesium hydroxide (11) ~ (15), (20)

[0091] Magnesium hydroxide (11)-(15), (20) was produced by the method shown below.

[0092] Add 400 ml of magnesium chloride aqueous solution (Wako Pure Chemical Industries, Ltd.) adjusted to a concentration of 0.5 mol / L in the autoclave and boric acid (manufactured by BORAX) in an appropriate amount within the range of 0.01 to 150 mol % relative to magnesium chloride, and stir under 121 ml of 3N caustic soda solution was added dropwise and reacted at room temperature (25° C.) for 30 minutes to obtain a magnesium hydroxide particle suspension.

[0093] The suspension was hydrothermally treated at 180°C for 2 hours, dehydrated, washed with water (200 ml), and dried at 105°C for 24 hours to obtain magnesium hydroxide having a predetermined aspect ratio and BET specific surface area. The obtained magnesium hydroxide is then surface-treated with a silane coupling agent and oleic acid to obtain magnesium hydroxide (11)-(15) and (20). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com