Exhaust heat airborne follow type hydrogen production plant with built-in thermostat

A technology for a hydrogen production device and a thermostat, which is applied in the field of hydrogen production devices, can solve the problems of uneven heating of the catalyst, easy aging, short service cycle, etc. The effect of reducing the phenomenon and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

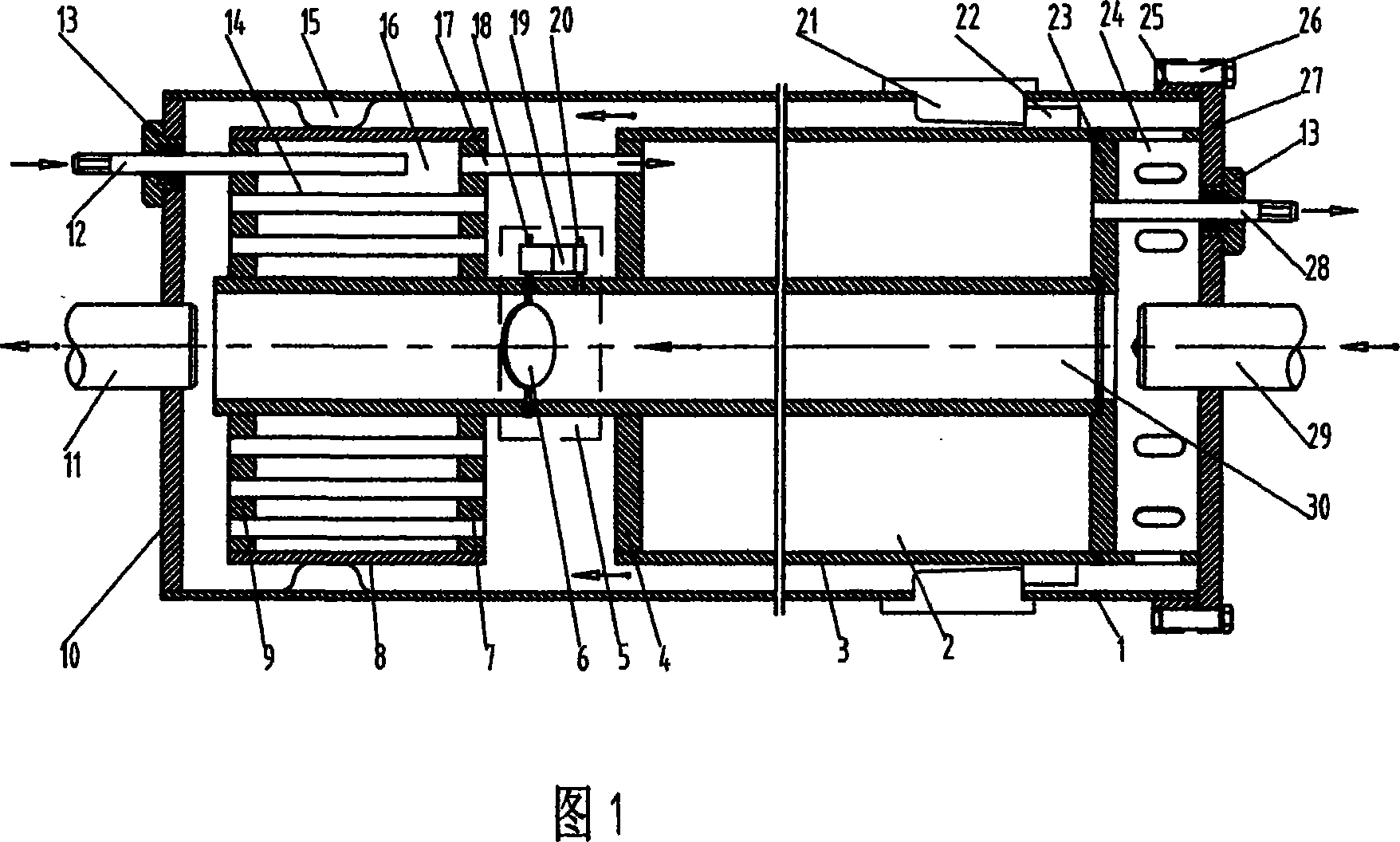

[0022] As shown in Figure 1, there is an exhaust pipe 11 at one end including the outer cylinder bottom 10, and the flange 25 at the other end is connected with the outer cylinder end cover 27 by bolts 26, and the outer cylinder end cover 27 is welded with an engine exhaust inlet. Air pipe 29, center tube 30 is arranged in the center of outer cylinder 1, and evaporative superheater 16 is equipped with in the left section of the central tube 30, and evaporative superheater 16 is welded on the central tube 30 by the middle hole of left and right tube plates 9, 7, left and right tube plates 9 and 7 are welded with several rows of tubes 14, and the outer peripheries of the left and right tube plates 9 and 7 are welded with evaporation superheater tubes 8. The tube plate 9 enters the evaporator superheater 16, and the middle section of the center pipe 30 has a thermostat 5, and the thermostat 5 consists of a throttle valve 6, a shaft 18, a curled bimetallic sheet 19, and adjusting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com