Phase change heat-storage thermoregulation polymerization wooden plate

A technology of phase change heat storage and composite panels, applied in the field of polymer wood panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with specific embodiments, but does not constitute any limitation to the protection scope of the present invention.

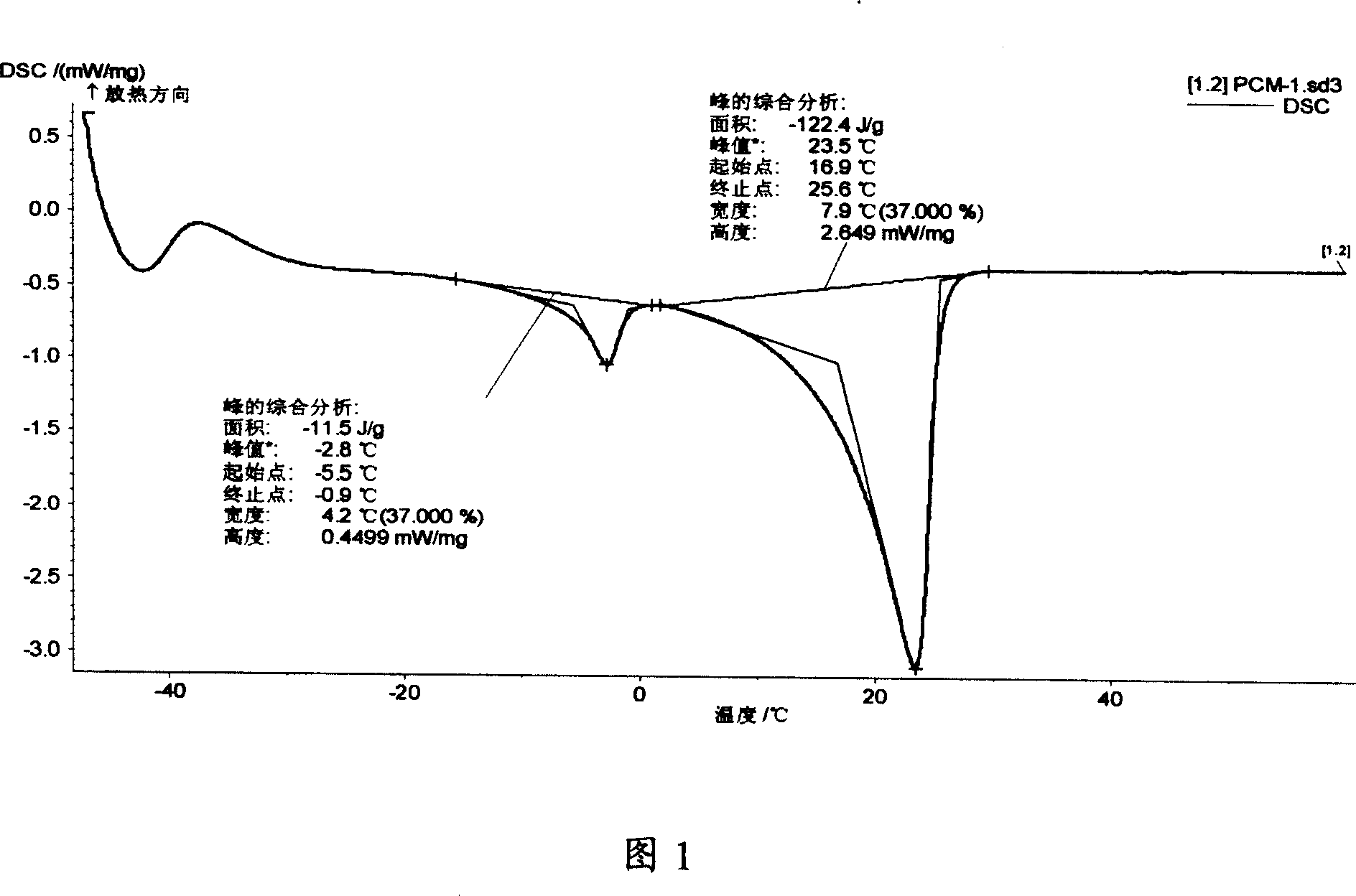

[0013] The phase change temperature and the phase change enthalpy of the microcapsule phase change material mentioned in the present invention are measured and can adopt differential scanning calorimeter (DSC), at N 2 Under protection, the heating rate is 5°C / min, and the measurement temperature range is -40°C to 200°C. The measured temperature corresponding to the peak top of the main absorption peak is the phase transition temperature. Between the start temperature and the end temperature of the peak, the absorption The heat corresponding to the area enclosed by the heat peak and the baseline is the phase change enthalpy. Its curve is shown in Figure 1.

[0014] Raw material ratio: 60 mesh wood powder 55wt%, high-density polyethylene (HDPE) 35wt%, compatibilizer 4.0wt%, conventional lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com