Load type polymerization catalyzed system, preparation method and application

A catalytic system and carrier technology, applied in the field of supported catalytic systems and their preparation, can solve problems such as inability to directly apply, and achieve the effects of simplified post-processing process, easy availability of raw materials, and control of polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

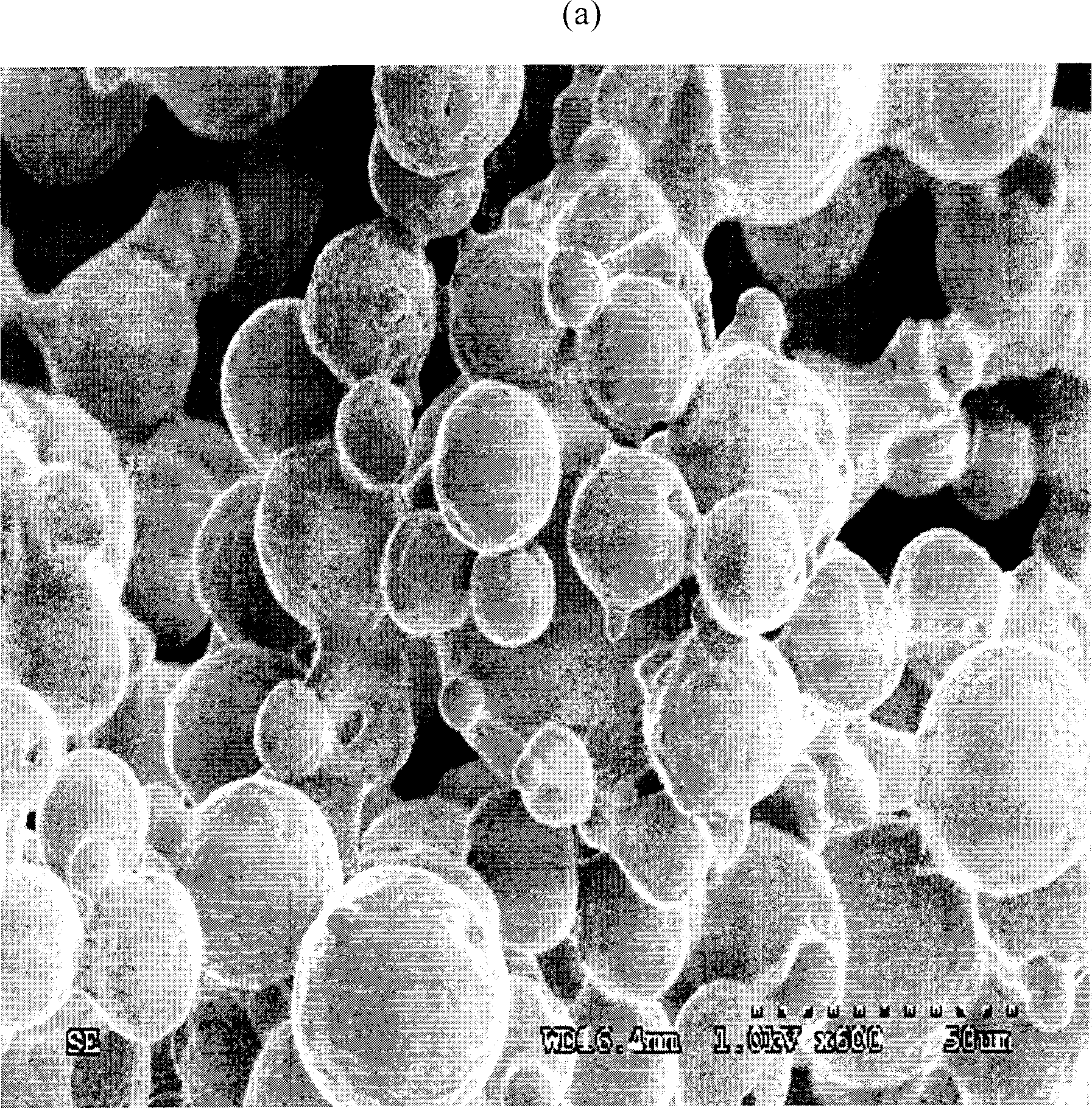

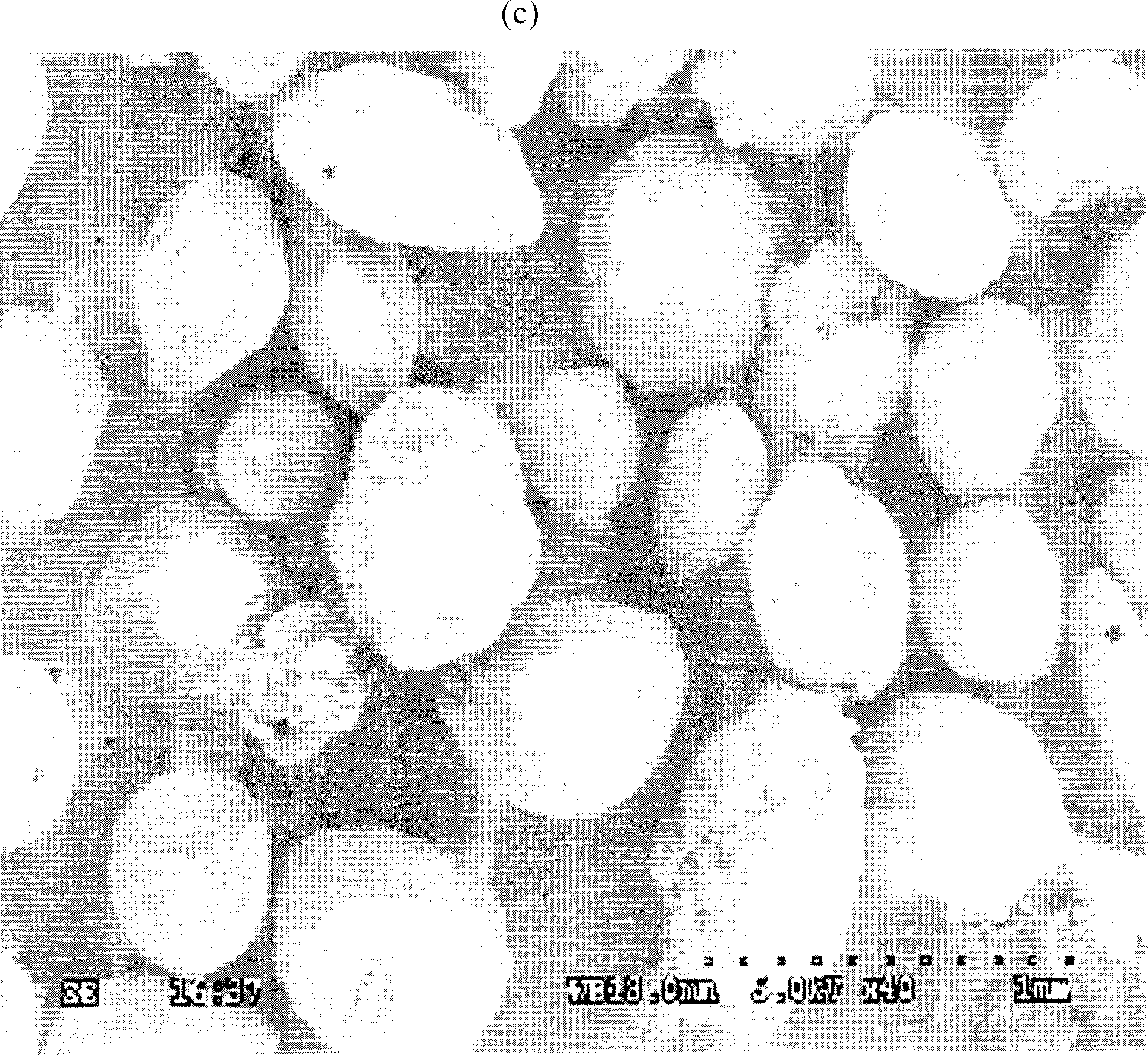

[0037] 1 Preparation process of supported catalyst

[0038] Vacuumize and fill nitrogen in the reaction kettle, repeat several times, add 4.54 grams of MgCl 2 .2.97C 2 h 5 OH, and about 100 ml of n-hexane was added, and 29.3 ml of 10% MAO toluene solution was added dropwise at -30°C (in about 0.5 to 1.0 hours), stirred at -30°C for 4 hours, then suction filtered and washed with hexane Twice, dry.

[0039] Add 50 ml of toluene solution of 0.1388 g of nickel complex as shown in the figure below, and stir at room temperature for 4 hours. Filter with suction, wash with hexane until the filtrate is almost colorless, and then dry to obtain a light yellow powder.

[0040]

[0041] 2 Catalyst analysis results

[0042] 3 norbornene polymerization:

[0043] Polymerization medium toluene: Vacuumize a dry 100 ml Schlenk bottle with a stirring magnet in sequence, fill it with nitrogen and replace it three times, make the reaction system in a nitrogen environment, add 0.1630 g of...

Embodiment 2

[0046] 1 Preparation process of supported catalyst

[0047] Vacuumize and fill the reactor with nitrogen, repeat several times, add 5.48 grams of MgCl 2 2.97C 2 h 5 OH, and about 100 ml of n-hexane was added, 35.4 ml of 10% MAO toluene solution was added dropwise at 0°C (within about 0.5 to 1.0 hours), stirred at 0°C for 4 hours, then suction filtered and washed twice with hexane ,dry.

[0048] Add 50 ml of toluene solution of 0.1675 g of nickel complex as follows, and stir at room temperature for 4 hours. Filter with suction, wash with hexane until the filtrate is almost colorless, and then dry to obtain a light yellow powder.

[0049]

[0050] 2 Catalyst analysis results

[0051] 3 norbornene polymerization:

[0052]Polymerization medium toluene: vacuumize the dry 100 milliliter Schlenk bottle with a stirring magnet, and replace it with nitrogen for three times, so that the reaction system is in a nitrogen environment, add 0.1048 grams of the catalyst described i...

Embodiment 3

[0055] 1 Preparation process of supported catalyst

[0056] Vacuumize and fill nitrogen in the reaction kettle, repeat several times, add 3.42 grams of MgCl 2 2.97C 2 h 5 OH, and about 100 ml of n-hexane was added, 33.9 ml of 10% MAO toluene solution was added dropwise at -30°C (within about 0.5 to 1.0 hours), stirred at -30°C for 4 hours, then suction filtered and washed with hexane Twice, dry.

[0057] Add 50 ml of toluene solution of 0.4182 g of nickel complex as shown in the figure below, and stir at room temperature for 4 hours. Filter with suction, wash with hexane until the filtrate is almost colorless, and then dry to obtain a light yellow powder.

[0058]

[0059] 2 Catalyst analysis results

[0060] 3 norbornene polymerization:

[0061] Polymerization medium toluene: vacuumize the dry 100 ml Schlenk bottle with a stirring magnet, and replace it with nitrogen for three times, so that the reaction system is in a nitrogen environment, add 0.0381 grams of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Conversion rate | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com