Emulsion of sunlight irradiation crosslinking hud polymer, preparation method and application

A technology of polymer emulsion and sunlight, applied in the direction of latex paint, etc., can solve the problems of inaccurate preparation ratio, short pot life of two-component paint, high toxicity of raw materials, etc., and achieve outstanding environmental protection performance, good blocking resistance, drying fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The components of the solar radiation crosslinked core-shell polymer emulsion of embodiment one, embodiment two, embodiment three are shown in the following table:

[0034] Table 1

[0035]

[0036] Methyl methacrylate

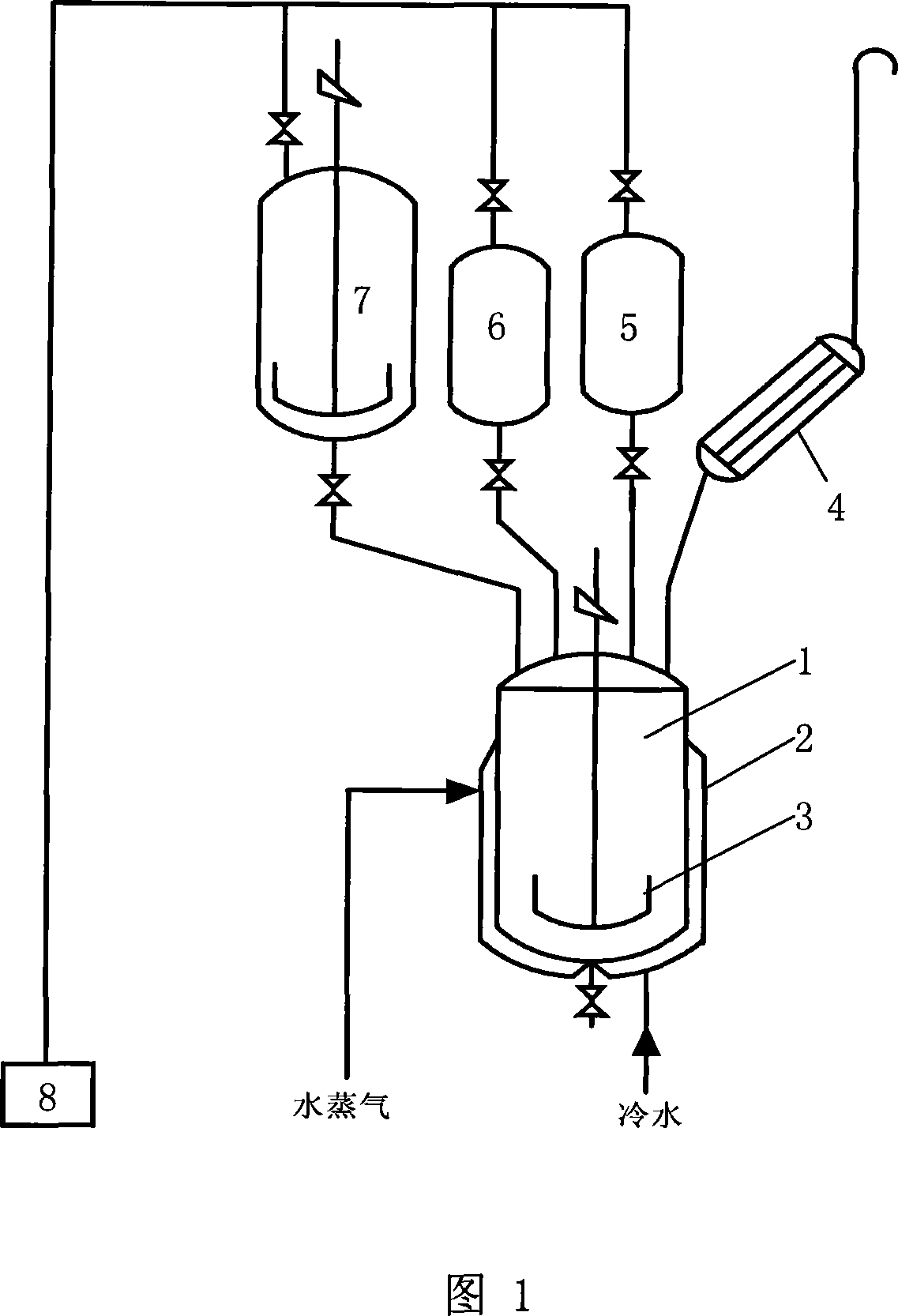

[0037] The preparation device of solar radiation crosslinked core-shell polymer emulsion is shown in Figure 1, including polymerization kettle 1, jacket 2, agitator 3, condenser 4, initiator header tank 5, regulator header tank 6, unit Body height tank 7, vacuum pump 8, when specifically preparing sunlight irradiation cross-linked core-shell polymer emulsion, the core emulsion is prepared first: add deionized water required for the formula into polymerization kettle 1, and mix the total amount of monomers by 1.0 to 5.0 % of the emulsifier, 0.1-1.0% of the buffering agent of the total amount of mixed monomers are put into the polymerization kettle 1 to dissolve, and the temperature is raised to 50-90° C., and 50% of the total amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com