Super-high molecular weight polyethylene catalyzer and preparation method thereof

A technology of ultra-high molecular weight and catalyst, applied in the production of bulk chemicals, etc., can solve problems such as environmental pollution, and achieve the effects of high bulk density, simple and feasible preparation method, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

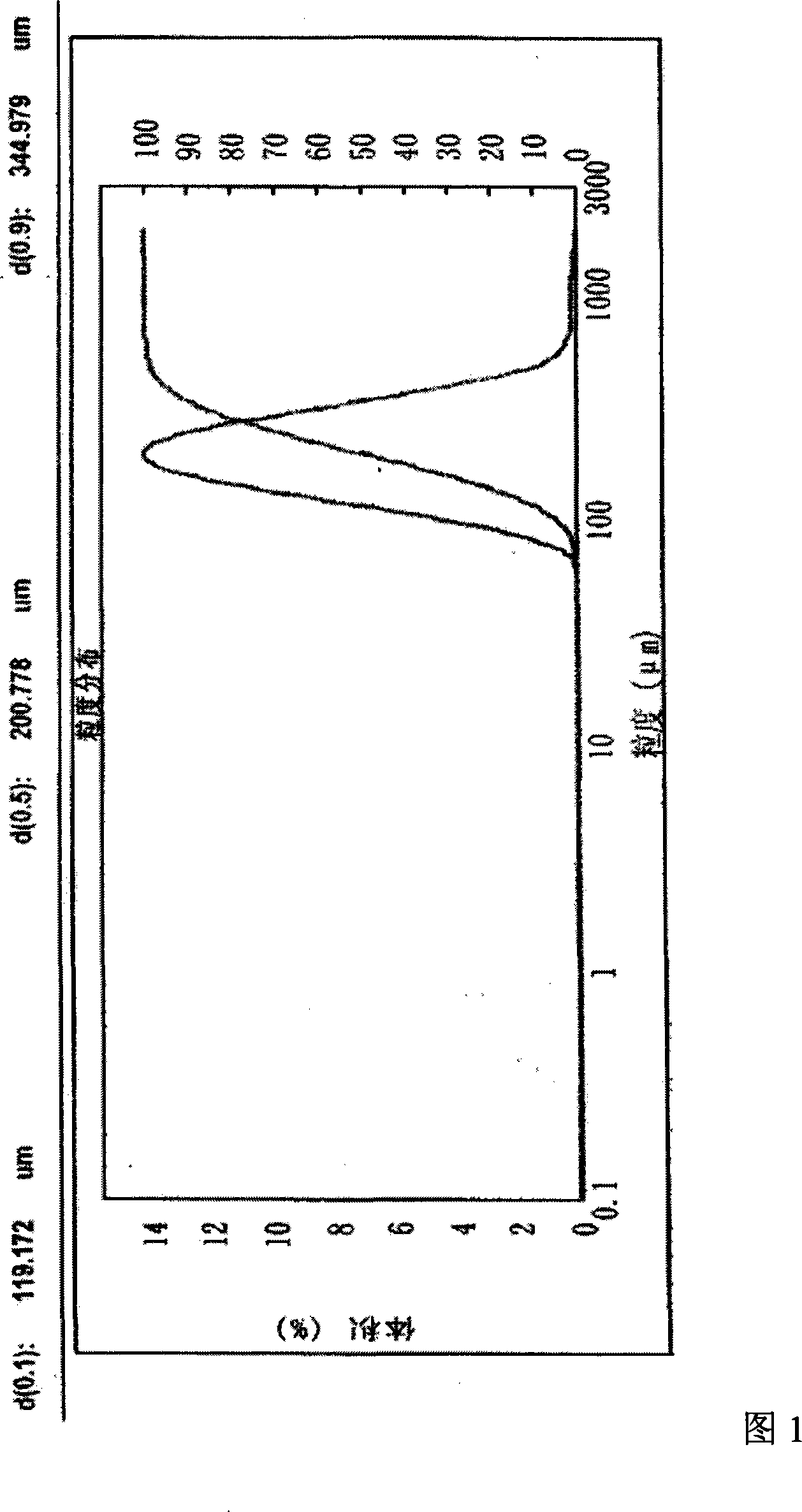

Image

Examples

Embodiment 1

[0049] Add 60ml of n-heptane, 0.5ml of ethyl benzoate, 4.2g of anhydrous magnesium chloride into a 250ml four-neck flask with a heating system, a stirring device and a condensing system and purged with nitrogen, stir well, drop Add 28ml of 2-ethylhexanol to the system. After the dropwise addition, raise the temperature of the system to 100°C, and keep the reaction at this temperature for 2 hours to obtain a magnesium compound solution. After cooling to room temperature, add 10ml of tetrachloride Add the mixture of silicon and 10ml of n-heptane dropwise to the above solution, stir and react for 0.5 hours after the dropwise addition, then add 2ml of titanium tetrachloride and raise it to 70°C, keep the reaction at this temperature for 1 hour and then cool naturally . After cooling to room temperature, the solid was washed three times with 150 ml of n-hexane, and vacuum-dried at room temperature to obtain a light yellow powdery solid substance with good fluidity. After sampling ...

Embodiment 2

[0055] Do not add ethyl benzoate, all the other are the same as in Example 1.

[0056] Polymerization test is with embodiment 1.

[0057] The polymerization test results are shown in Table 1.

Embodiment 3

[0059] Replace silicon tetrachloride with dichlorodiphenylsilane in an amount of 20ml, and the rest are the same as in Example 1.

[0060] Polymerization test is with embodiment 1.

[0061] The polymerization test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com