Aqueous long-acting anticorrosion paint and preparation method thereof

A long-term anti-corrosion, water-based technology, applied in the direction of anti-corrosion coatings, etc., can solve the problems of easy aging and deterioration, and achieve the effect of strong adhesion and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] Embodiment 1: The water-based long-acting anti-corrosion coating of the present invention is made by 50 kilograms of zinc powder passing through a 625-mesh sieve under constant stirring, after adding it to component A, and filtering it through an 80-mesh sand net, wherein: The components are prepared as follows:

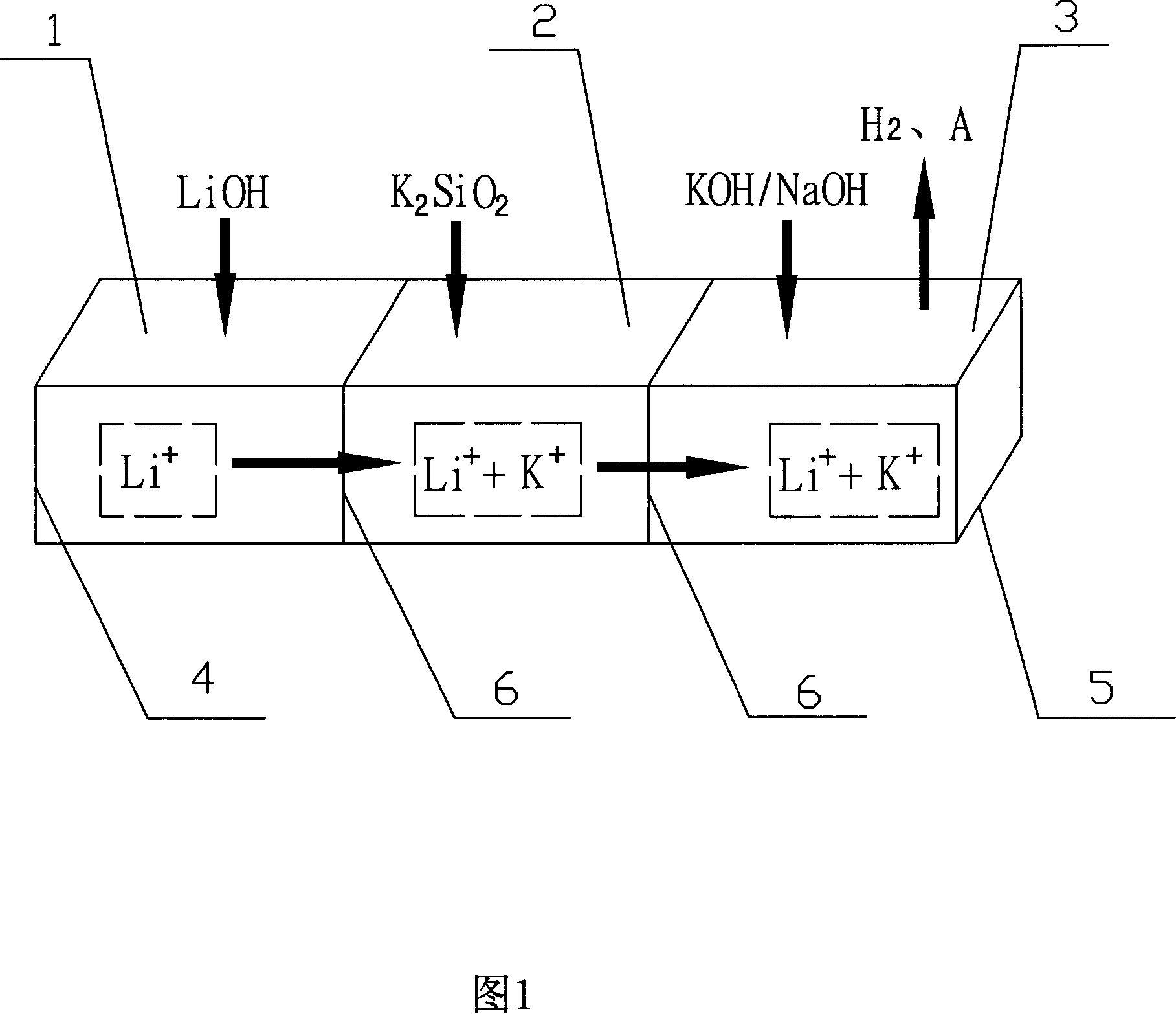

[0021] 1) Get 30 kilograms of potassium silicate sol and 2 kilograms of heavy deionized water, 2.5 kilograms of potassium hydroxide, 7.5 kilograms of lithium hydroxide, and make composite potassium silicate lithium solution A by electrodialysis;

[0022] 2) Get 15 kilograms of heavy composite potassium silicate lithium solution A, under constant stirring, add 2 kilograms of monomethyltriethoxysilane, then slowly add 5 kilograms of water-based epoxy silicone acrylic resin, and Keep warm at 20-70°C for 6 hours, then add 1 kg of ethylene glycol, 0.3 kg of polybutyl titanate, 0.3 kg of sorbitan lauric acid monoester, and 1 kg of lauryl alcohol Stir the fat thorou...

Embodiment approach 2

[0024] Embodiment two: the water-based long-acting anti-corrosion coating of the present invention is made by 90 kilograms of zinc powder passing through a 625 mesh sieve under constant stirring, after it is added to component A, and filtered through an 80 mesh sand net, wherein: The components are prepared as follows:

[0025] 1) Get 80 kilograms of potassium silicate sol and 20 kilograms of heavy deionized water, 7.5 kilograms of potassium hydroxide, 22.5 kilograms of lithium hydroxide, and make composite potassium silicate lithium solution A by electrodialysis, wherein The value range of X is 30;

[0026] 2) Get 45 kilograms of heavy composite potassium silicate lithium solution A, under constant stirring, add 15 kilograms of monomethyltriethoxysilane, then slowly add 55 kilograms of water-based epoxy silicone acrylic resin, and Keep warm at 20-70°C for 18 hours, then add 10 kg of ethylene glycol, 2 kg of polybutyl titanate, 3 kg of sorbitan lauric acid monoester, and 10 k...

Embodiment approach 3

[0028] Embodiment 3: The water-based long-acting anticorrosive paint of the present invention is made by 70 kilograms of zinc powder passing through a 625 mesh sieve under constant stirring, after adding it to component A, and filtering it through an 80 mesh sand screen, wherein: The components are prepared as follows:

[0029] 1) Get 55 kilograms of potassium silicate sol and 11 kilograms of heavy deionized water, 5 kilograms of potassium hydroxide, 15 kilograms of lithium hydroxide, and make composite potassium silicate lithium solution A by electrodialysis, wherein The value range of X is 20;

[0030] 2) Get 30 kilograms of heavy composite potassium silicate lithium solution A, under constant stirring, add 9.5 kilograms of monomethyltriethoxysilane, then slowly add 30 kilograms of water-based epoxy silicone acrylic resin, and Keep warm at 20-70°C for 12 hours, then add 5.5 kg of ethylene glycol, 1.15 kg of polybutyl titanate, 1.15 kg of sorbitan lauric acid monoester, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com