Nanometer iron-series catalyst and preparation method and device thereof

A nano-iron and catalyst technology, which is applied in nanostructure manufacturing, chemical instruments and methods, physical/chemical process catalysts, etc. The preparation process is simple, the stability is good, and the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

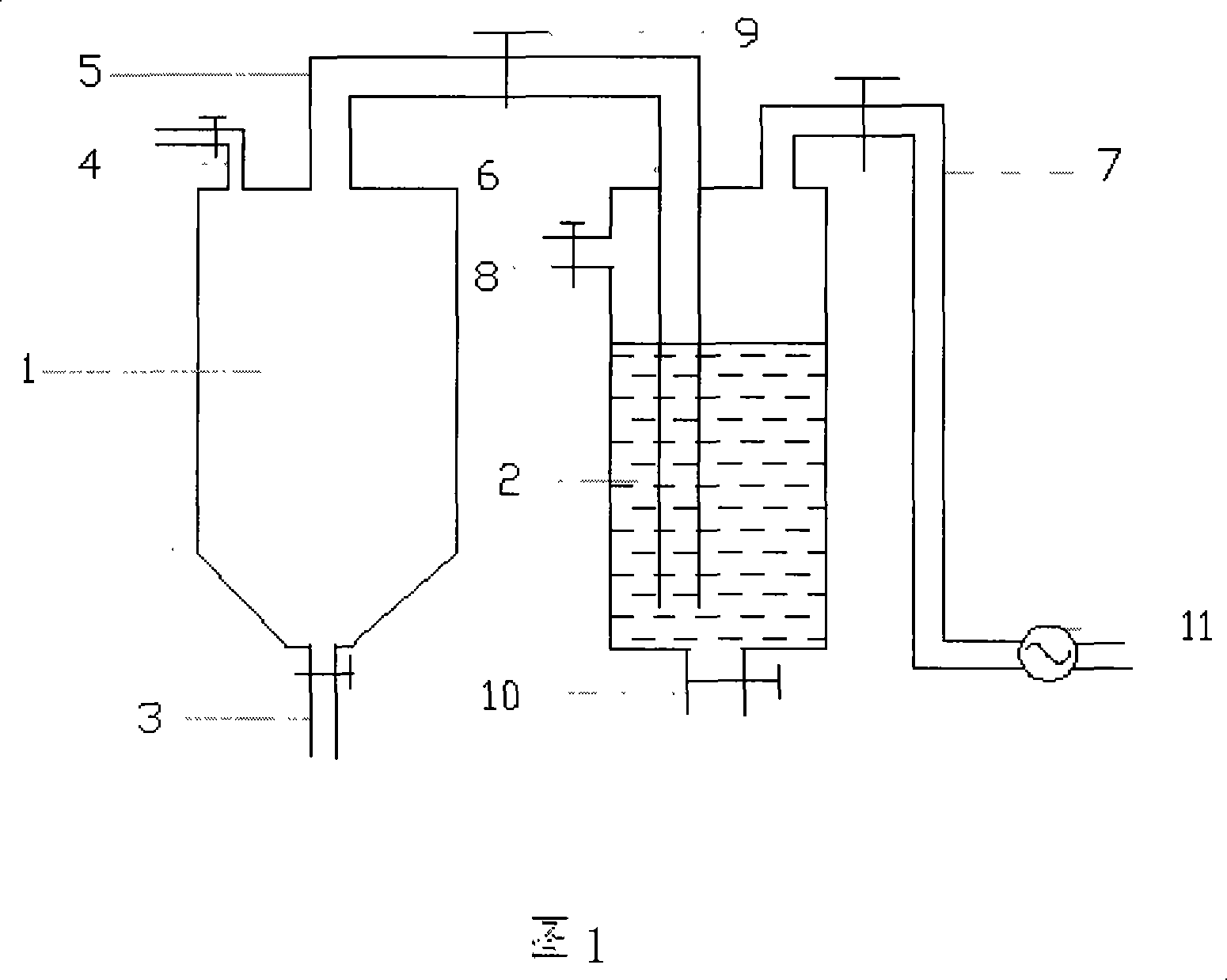

[0024] The device used for preparing the nano-iron series catalyst of the present invention is made up of reaction chamber 1 and settling chamber 2, and reaction chamber 1 is provided with pentacarbonyl iron liquid or vapor inlet 3, iron particle outlet 5 and protective gas inlet 4, and settling chamber is provided with There are iron particle inlet 6, gas outlet 7, liquid isolation medium inlet 8 and material outlet 10, wherein the nano-iron particle inlet 6 extends into the liquid isolation medium of the settling chamber, the gas outlet 7 is connected with the vacuum pump 11, and the reaction chamber iron particle outlet 5 It is connected with the iron particle inlet 6 of the settling chamber through a high-pressure valve 9 .

[0025] The preparation method of nano-iron series catalyst of the present invention is made up of the following steps:

[0026] ① Inject a liquid medium into the settling chamber 2, vacuumize or replace the air in the reaction chamber 1 and the settli...

Embodiment 1

[0036] Inject heavy oil into the 2L settling chamber 1 until the volume occupies 1L of the settling chamber, open the protective gas inlet 4 and the high-pressure valve 9, and replace the air in the high-pressure reaction chamber 1 and the settling chamber 2 with a volume of 2L with high-purity nitrogen gas. After the replacement is completed, Close the valve 9, and continue to feed high-purity nitrogen into the reaction chamber 1 to 0.1MPa; start the heating device to raise the temperature to 285°C, open the iron pentacarbonyl inlet 3, and feed 0.4L iron pentacarbonyl steam, and the iron pentacarbonyl enters the reaction chamber to decompose. Prepare nano-iron particles; open high-pressure valve 9 and settling chamber air outlet 7, start vacuum pump simultaneously, nano-iron particles enter settling chamber 2 through iron particle outlet 5 and iron particle inlet 6 and disperse in heavy oil; open discharge port 10 to The heavy oil dispersed with nano-iron particles is stored i...

Embodiment 2

[0039]The same preparation method and device as in Example 1 were used to produce iron-based catalysts, wherein the liquid isolation medium was phenol, the temperature of the reaction chamber was raised to 400°C, the pressure of high-purity nitrogen was 2.5Mpa, and 5L of iron pentacarbonyl steam was introduced. The coal type was changed to Shenhua Dongsheng lignite for coal liquefaction experiment, the coal conversion rate was 89.5%, and the oil recovery rate was 57%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com