Method for deinking and decoloring office waste paper by using ion liquid

An ionic liquid, office waste paper technology, applied in the processing of waste paper, recycling technology, papermaking, etc., to achieve the effects of mild operating conditions, low price, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

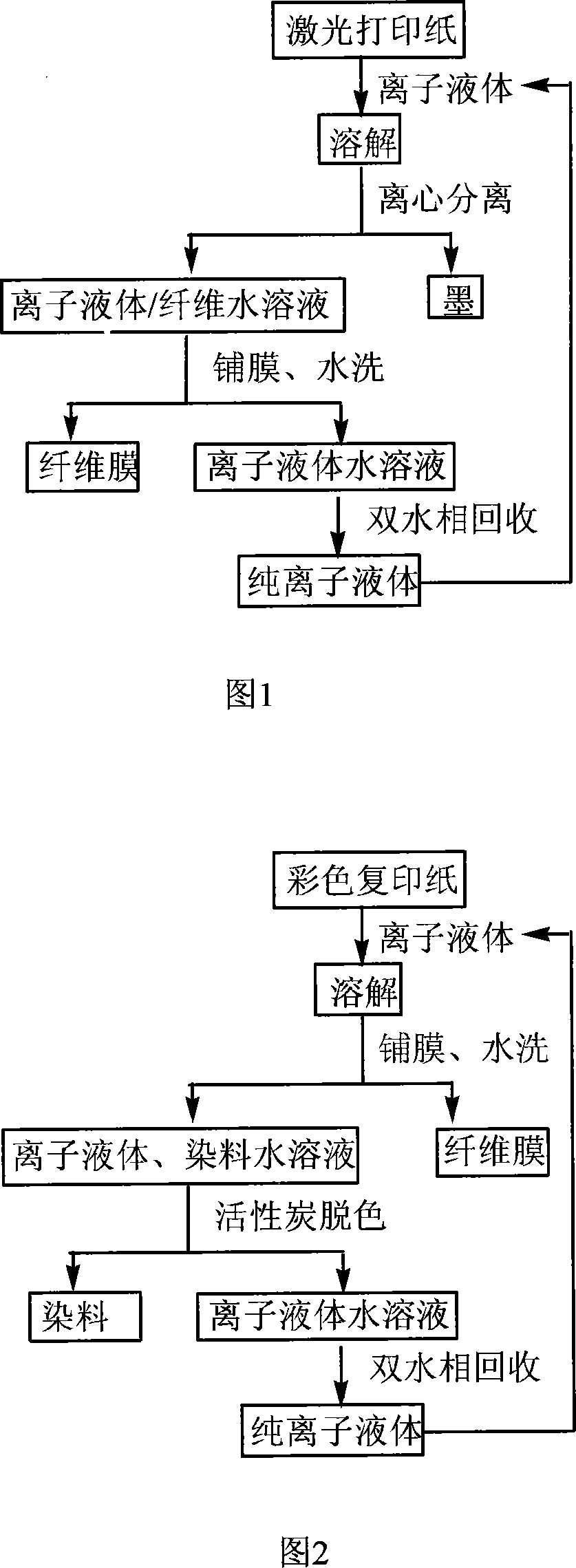

Embodiment 1

[0035]The office waste paper used in the deinking experiment in the present invention is laser-printed office waste paper printed with ink. Adequate drying of office waste paper and ionic liquids is a must. Mix the laser printing waste paper with ink printed on the shredder and the ionic liquid ([BMIm]Cl) at a mass ratio of 1:10, that is, 0.5g:5g, and microwave the ionic liquid to melt it and add it. Waste paper, stir evenly so that the waste paper is completely soaked, and perform intermittent heating under the microwave power of 210W: heating for 10 seconds each time, then take it out and cool it in an ice-water bath for about 60s to 40°C, and then microwave for 10 seconds. Repeat for a total of about 1800 seconds of heating. Take a small amount of liquid to lay a film and press it, and observe under a microscope that there is no cellulose filament, then the cellulose is completely dissolved, and an ionic liquid / cellulose solution is obtained; the ink particles are suspende...

Embodiment 2

[0037] The office waste paper used in the decolorization experiment in the present invention is color copy paper. Adequate drying of office waste paper and ionic liquids is a must. Mix the color copy paper shredded with a shredder and the ionic liquid ([BMIm]Cl) at a mass ratio of 1:6.7, that is, 0.45g:3g, and microwave heating until the ionic liquid is melted, and then add waste paper and stir to make the waste paper. Completely soaked, heated intermittently under microwave power of 210W for 10 seconds each time, then taken out and cooled in an ice-water bath for about 60s to 40°C, then microwaved for 10 seconds, repeated in turn, heated for a total of 1500 seconds, take a small amount Lay the liquid film and press the tablet, and observe under the microscope that there is no cellulose filament, then the cellulose is completely dissolved, and thus the ionic liquid / cellulose solution is prepared.

[0038] The ionic liquid / cellulose solution was filmed, and the film was orange...

Embodiment 3

[0040] Take 1 g of the cellulose / ionic liquid solvent prepared in Example 1, spread it evenly in a polytetrafluoroethylene mold, and repeatedly soak and rinse with distilled water until the cellulose film is clear, transparent and colorless. Place the cellulose film in a ventilated place at room temperature and dry naturally. A transparent regenerated cellulose film was obtained. The film has better toughness and better mechanical properties.

[0041] The ionic liquid is dissolved in water and separated from the cellulose membrane. Take 5ml of water and ionic liquid clear solution in a test tube, add about 3g K 2 CO 3 Shake on a vortex mixer for 5 minutes to make K 2 CO 3 Completely dissolve and mix evenly, stand to form two phases, and the upper layer is the ionic-rich liquid phase. The upper phase ionic liquid is collected and subjected to distillation, concentration and drying to obtain pure ionic liquid with a recovery rate of 97%. The recovered ionic liquid can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com