Closed calcium carbide oven capacitance-increasing process

A process method, calcium carbide furnace technology, applied in the direction of chemical instruments and methods, furnaces, furnace types, etc., can solve the problems of increasing the diameter of copper pipes, increasing the height of the furnace cover, and large branch current, so as to shorten the length of the short network , stable furnace pressure, and increased current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] The present invention is not limited to the following best implementation mode, anyone can draw other various forms of products under the enlightenment of the present invention, but no matter make any changes in its shape or structure, all those with the same or the same characteristics as the present application Similar technical solutions are all within the protection scope of the present invention.

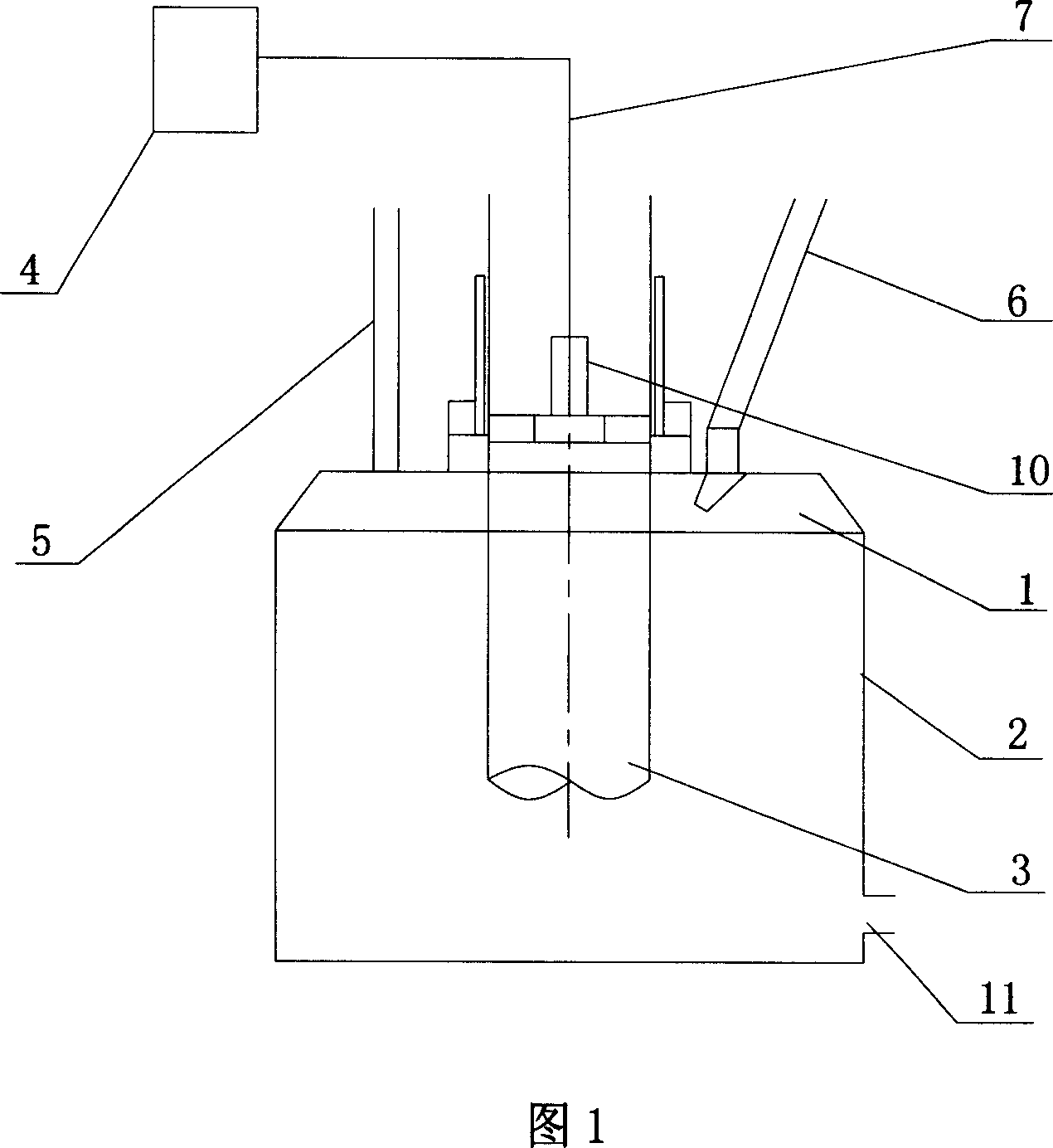

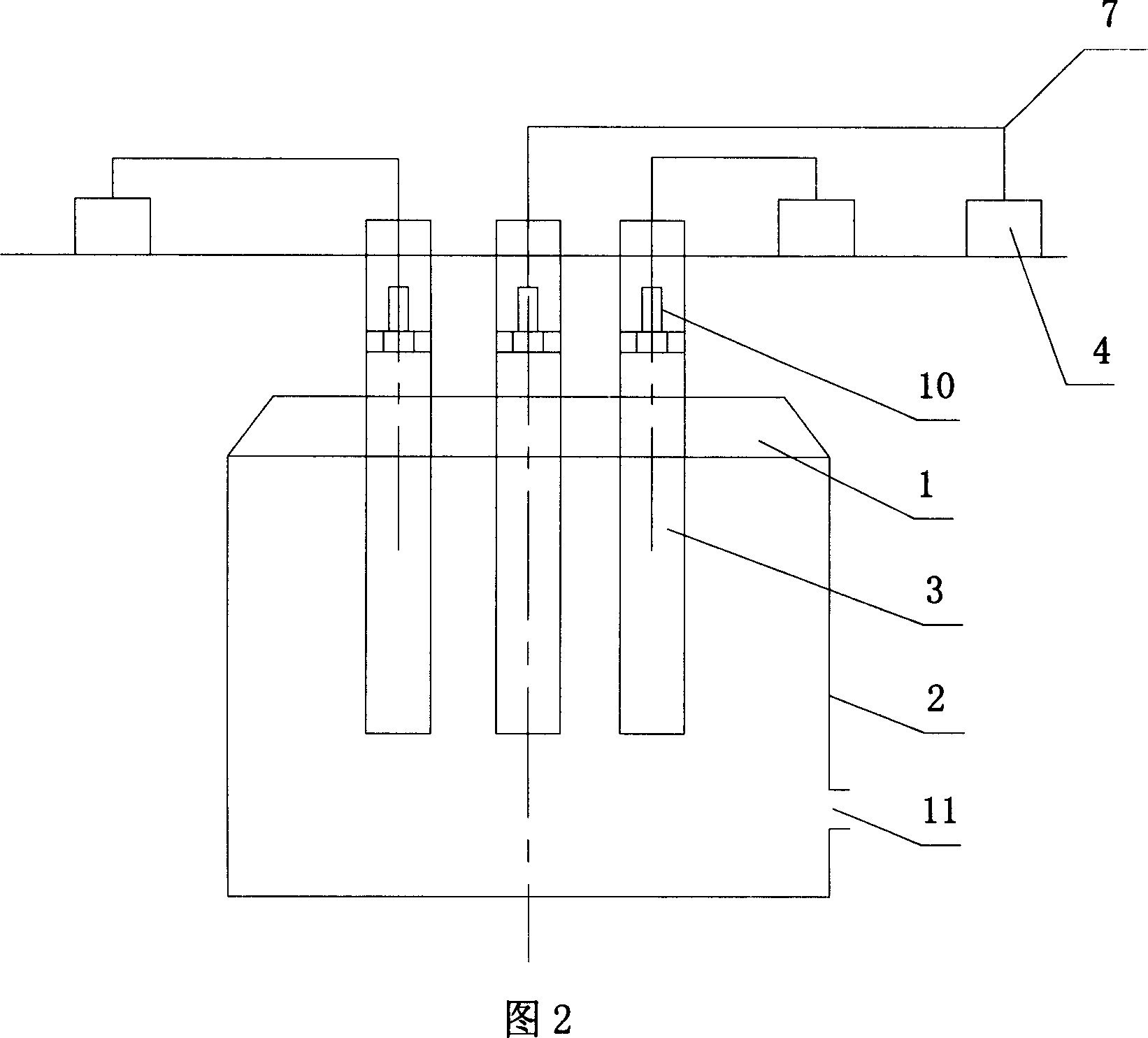

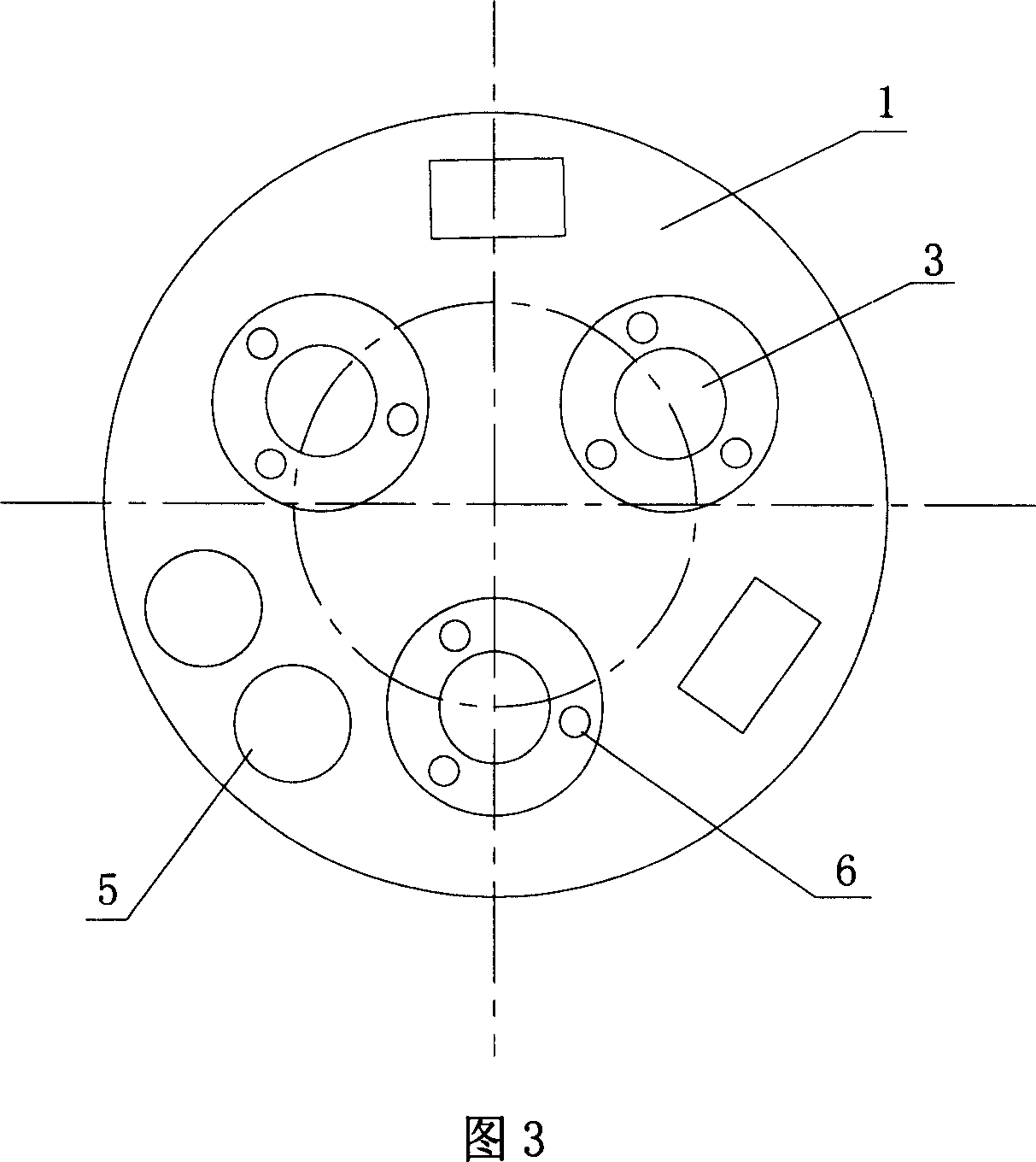

[0022] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention includes a furnace cover 1 provided with a body of furnace 2 and the top of the body of furnace 2, the bottom of the body of furnace 2 is provided with a furnace outlet 11, and the furnace cover 1 is provided with electrodes 3, charging mouth, flue gas channel 5, and each electrode 3 is connected to the electric furnace transformer 4 through the contact element 10, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com