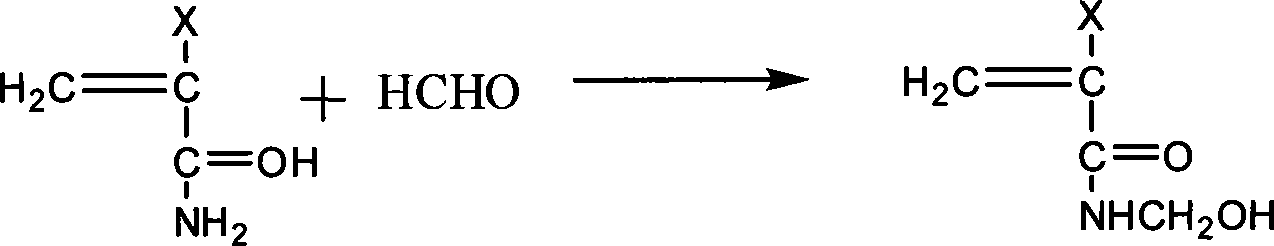

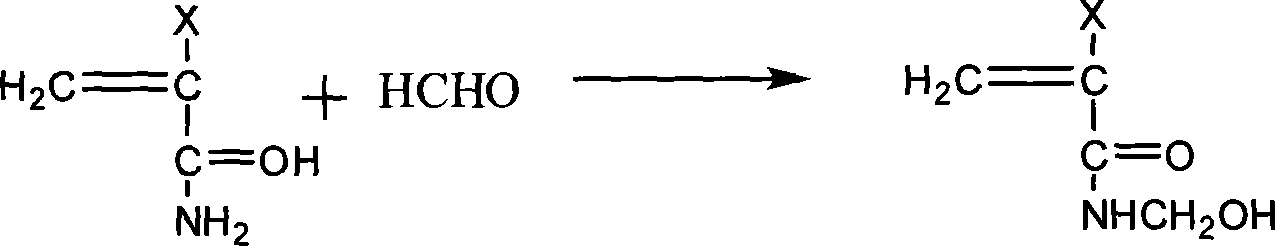

Method for preparing N-hydroxymethyl alkyl acrylamide

A technology of methylol alkyl acrylamide and alkyl acrylamide, which is applied in the field of preparation of N-methylol alkyl acrylamide, can solve the problems such as no product preparation method has been found, and achieve easy polymerization and good storage stability , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 188g of deionized water, add it into a 2000ml four-necked bottle, and start stirring. Add 485g of methacrylamide, control the temperature at 38-40°C, adjust the pH to 10.0-11.0 with an alkali solution with a mass concentration of 5%, and add 320g of formaldehyde aqueous solution. Constantly replenish the alkaline solution to keep the pH between 9.0 and 11.0, and react until the solution is clear. Then, keep warm at 40° C. for 2 to 2.5 hours. Add a certain amount of H 2 SO 4 , adjust the pH to 6-7, and stir for 5 minutes. Finally, 0.2 g of polymerization inhibitor was added and stirred thoroughly to obtain a uniform and stable aqueous solution product.

Embodiment 2

[0018] Take 390g of deionized water, add it into a 2000ml four-necked bottle, and start stirring. Add 490 g of methacrylamide, control the temperature at 20-25° C., and adjust the pH to 9.0-11.0 with an alkali solution with a mass concentration of 5%. The temperature was raised to 30-35°C, and 137g of paraformaldehyde was added. Raise the temperature to 38-40°C. Constantly replenish the alkaline solution to keep the pH between 9.0 and 11.0, and react until the solution is clear. Then keep it warm at 38°C for 2-3 hours, add H 2 SO 4 , adjust the pH to 6-7, and stir for 5 minutes. Finally, 0.15 g of polymerization inhibitor was added and stirred thoroughly to obtain a uniform and stable aqueous solution product.

Embodiment 3

[0020] Take 390g of deionized water, add it into a 2000ml four-necked bottle, and start stirring. Add 490g of methacrylamide, control the temperature at 30-35°C, and add 137g of paraformaldehyde. Raise the temperature to 38-40°C. Adjust the pH to between 9.0 and 11.0 with an alkali solution with a mass concentration of 5%, and react until the solution is clear. Then keep it warm at 38°C for 2-3 hours, add H 2 SO 4 , adjust the pH to 6-7, and stir for 5 minutes. Finally, 0.15 g of polymerization inhibitor was added and stirred thoroughly to obtain a uniform and stable aqueous solution product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com