Biosensor enzyme sensitive film and its preparation method

A technology of biosensors and sensitive membranes, applied in biochemical equipment and methods, measurement/inspection of microorganisms, instruments, etc., can solve the problems of low sensitivity of sensors, no application of biosensors, long electrode response time, etc., and achieve improvement Sensitivity, improve overall performance, improve long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

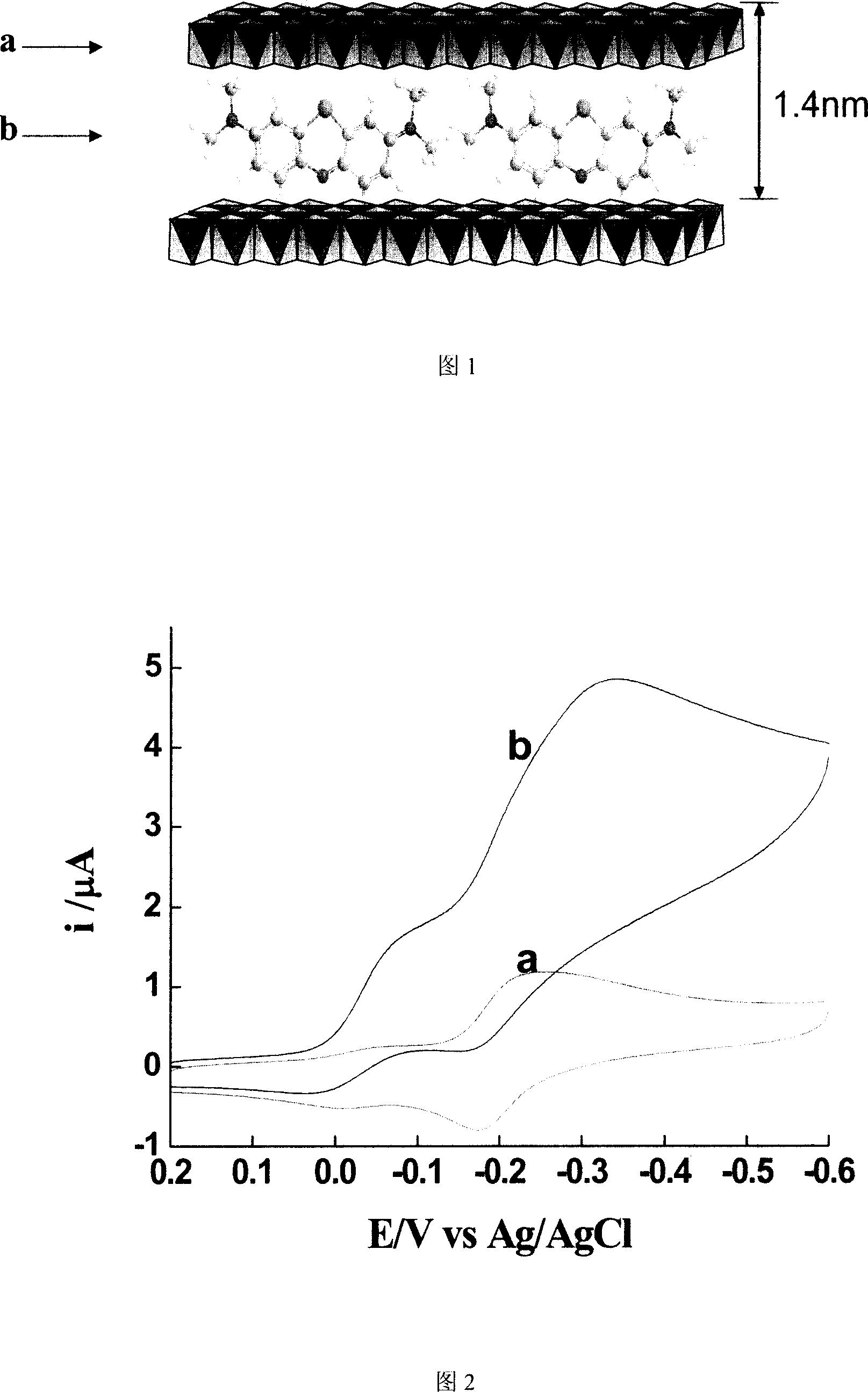

[0048] A Preparation of methylene blue intercalated manganese dioxide supramolecular structure material by stripping and reassembling

[0049] A-1. 200mL containing 0.8mol / L NaOH and 1.2mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.3mol / L Mn(NO 3 ) 2 solution, vigorously stirred and reacted for 20 minutes, filtered, transferred the filter cake to a polytetrafluoroethylene container, added 50mL NaOH solution with a concentration of 2.5mol / L, stirred into a paste, sealed the polytetrafluoroethylene container in water In a hot kettle, hydrothermally treat at 150°C for 16 hours, cool the hydrothermal kettle naturally to room temperature, open the kettle for suction filtration, wash the filter cake with deionized water until the pH value of the filtrate is 8, and dry the filter cake in an air atmosphere at 70°C for 7 Hour, obtain layered manganese dioxide;

[0050] A-2. Add 2.8g of the above-mentioned layered manganese dioxide solid powder to 260mL of...

Embodiment 2

[0058] A Preparation of methylene blue intercalated manganese dioxide supramolecular structure material by stripping and reassembling

[0059] A-1. 200mL containing 0.6mol / L NaOH and 1.5mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.4mol / L Mn(NO 3 ) 2 solution, vigorously stirred and reacted for 30 minutes, filtered, transferred the filter cake to a polytetrafluoroethylene container, added 50mL NaOH solution with a concentration of 2mol / L, stirred into a paste, sealed the polytetrafluoroethylene container in a hydrothermal In the kettle, hydrothermally treat at 160°C for 18 hours, cool the hydrothermal kettle naturally to room temperature, open the kettle for suction filtration, wash the filter cake with deionized water until the pH value of the filtrate is 9, and dry the filter cake in an air atmosphere at 80°C for 9 hours , to obtain layered manganese dioxide;

[0060] A-2. Add 2.5g of the above layered manganese dioxide solid powder to 300mL of...

Embodiment 3

[0068] A Preparation of methylene blue intercalated manganese dioxide supramolecular structure material by stripping and reassembling

[0069] A-1. 200mL containing 0.8mol / L NaOH and 1.5mol / L H 2 o 2 The mixed solution was quickly added to 100mL containing 0.5mol / L Mn(NO 3 ) 2 solution, vigorously stirred and reacted for 25 minutes, filtered, transferred the filter cake to a polytetrafluoroethylene container, added 50mL NaOH solution with a concentration of 2.3mol / L, stirred into a paste, sealed the polytetrafluoroethylene container in water In a hot kettle, conduct hydrothermal treatment at 160°C for 15 hours, cool the hydrothermal kettle naturally to room temperature, open the kettle for suction filtration, wash the filter cake with deionized water until the pH value of the filtrate is 8.5, and dry the filter cake in an air atmosphere at 75°C for 9 Hour, obtain layered manganese dioxide;

[0070] A-2. Add 2.0g of the above-mentioned layered manganese dioxide solid powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com