Processing method for silicon sheet surface

A treatment method and silicon wafer surface technology, applied to electrical components, climate sustainability, circuits, etc., can solve problems such as poor repeatability, uneven corrosion, pollution, etc., to simplify process steps, improve uneven corrosion, Improved repeatability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

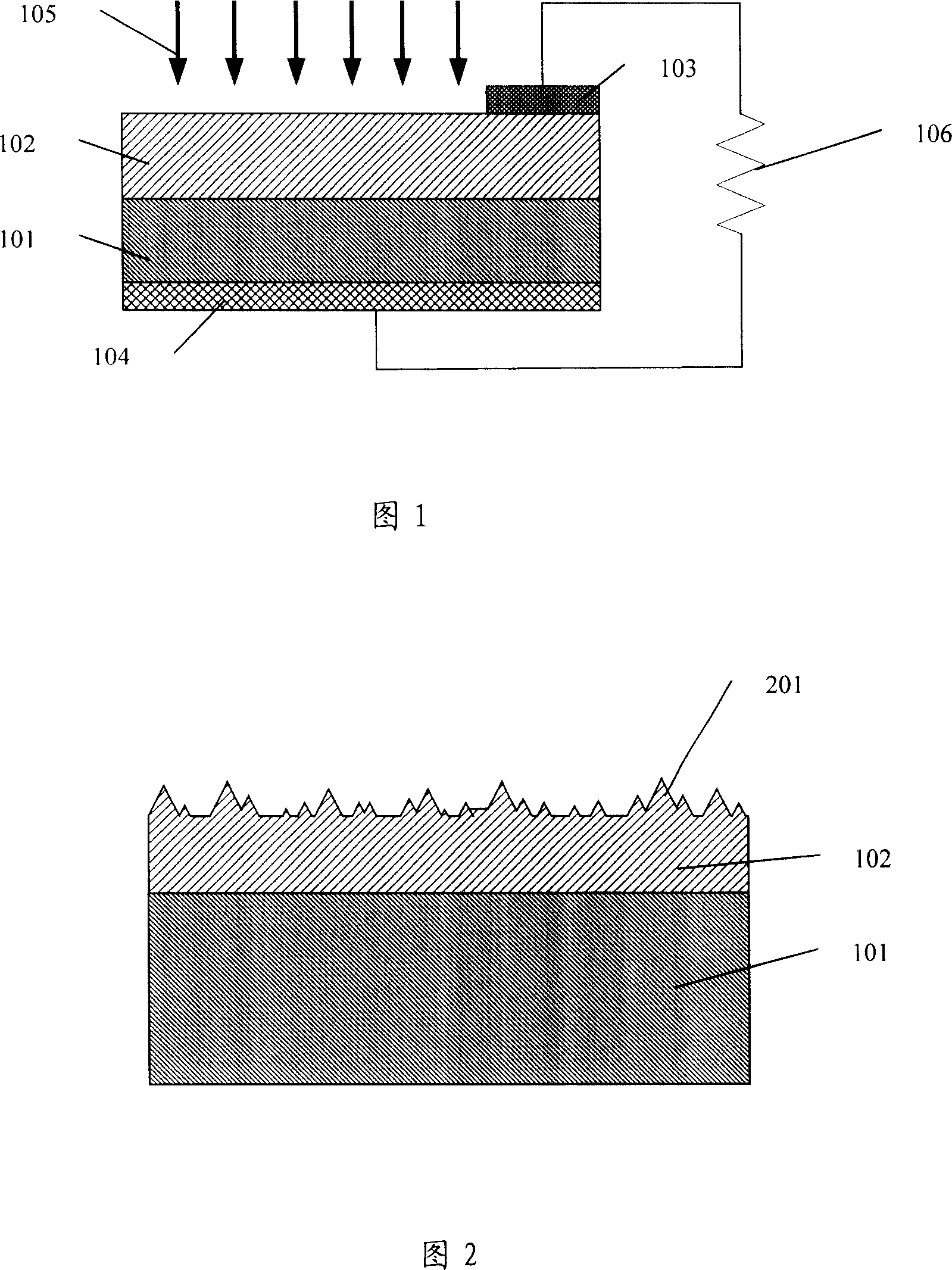

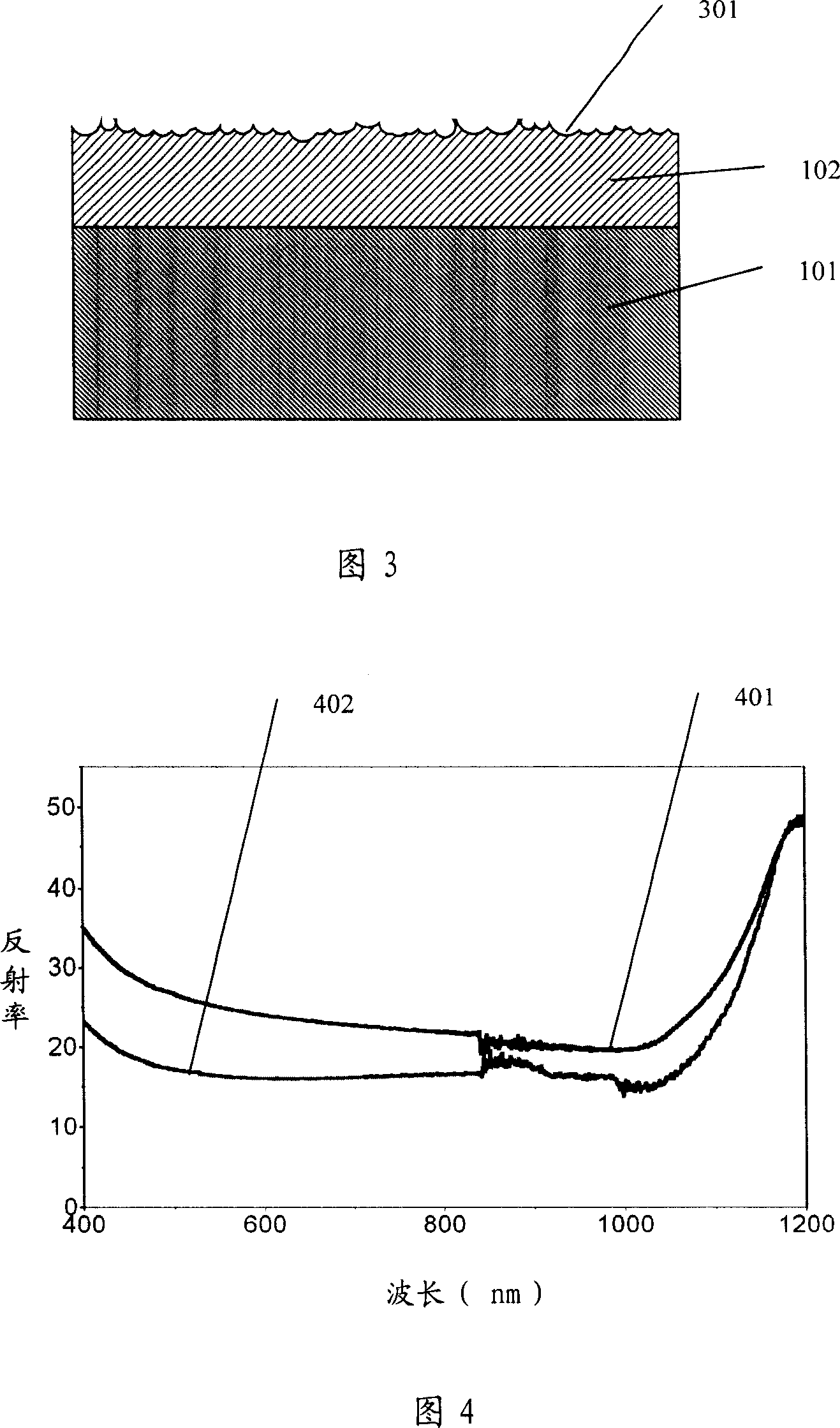

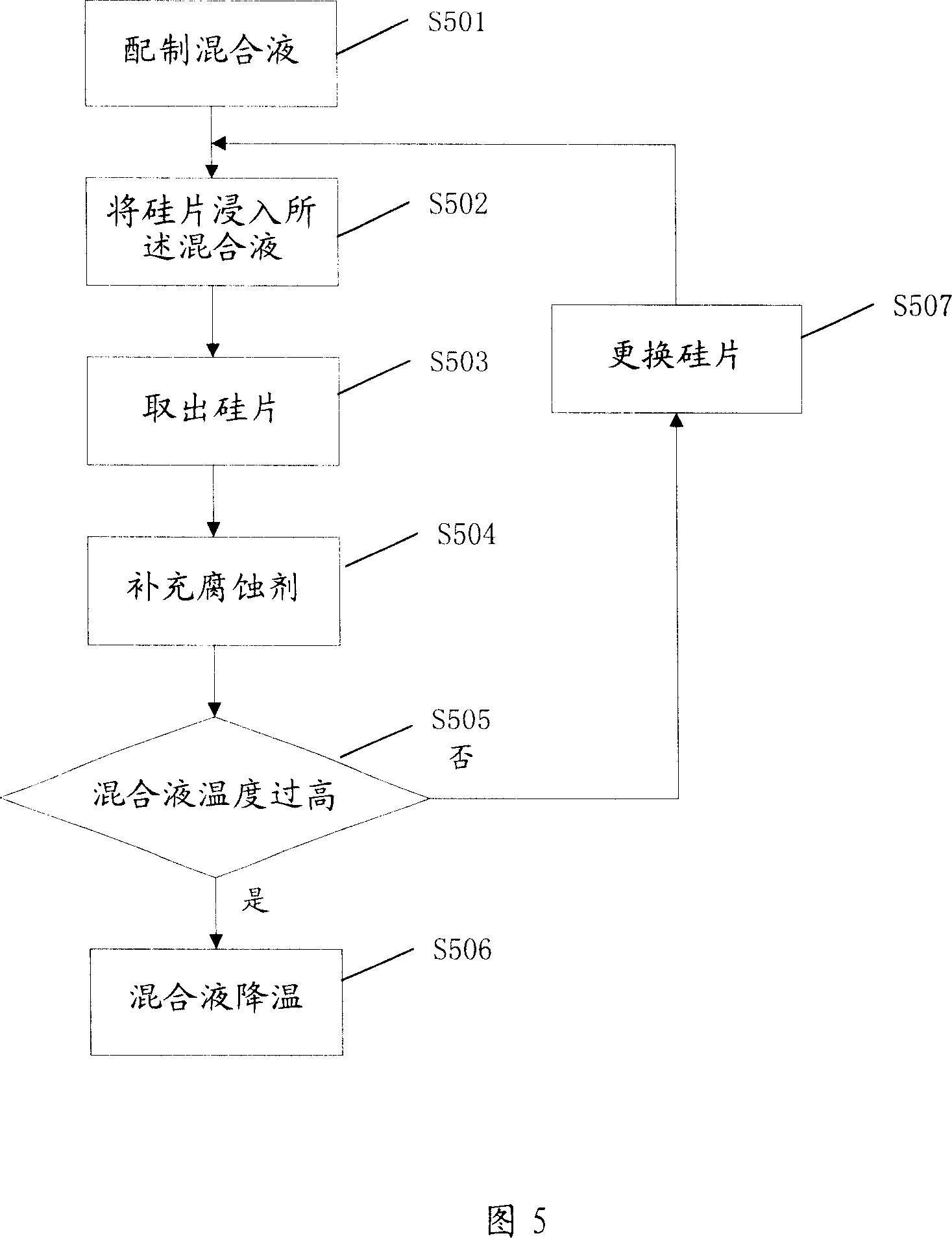

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] The silicon wafer surface treatment method of the present invention uses a mixed solution with a new formula to treat the silicon wafer surface, which can not only remove the damaged layer on the silicon wafer surface, but also form a suede surface on the silicon wafer surface, thereby improving device efficiency. In the mixed solution of the present invention, ammonium hydrofluoride (NH 4 HF 2 ), potassium nitrate (KNO 3 ) and sulfuric acid (H 2 SO 4 ), the amount used by each component in the mixed solution when preparing for the first time is called the preparation amount among the present invention, and the mol ratio of each component preparation amount is: 1% to 20% KNO 3 , 5% to 30% NH 4 HF 2 , and 50% to 95% concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com