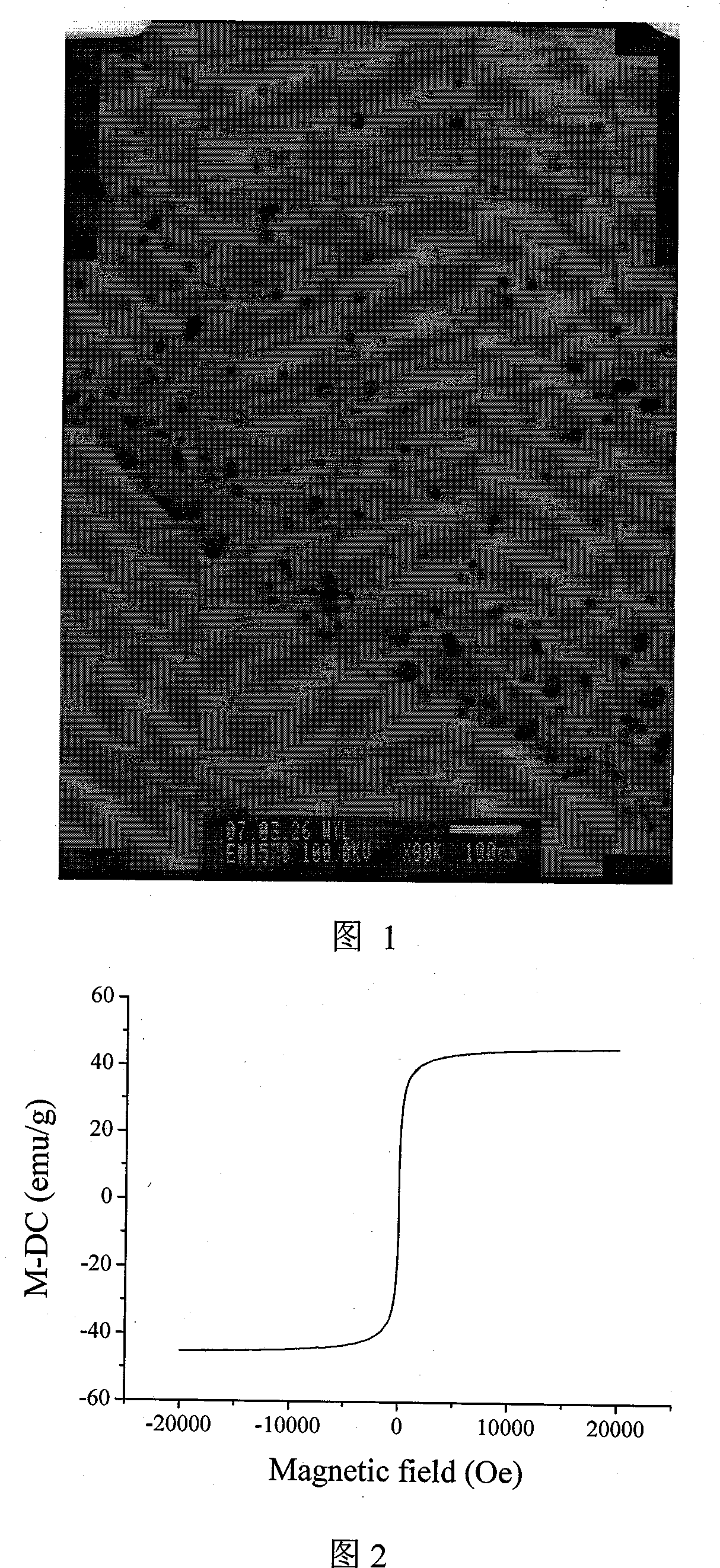

Chitose aquagel evoked original position synthesis of super-paramagnetism nano ferriferrous oxide particles

A ferroferric oxide and superparamagnetic technology, which is applied in the direction of iron oxide/hydroxide and ferric oxide, can solve the problems of complex chitosan methods and serious agglomeration of nanometer ferric oxide particles. Achieve good biocompatibility, mild conditions and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: present embodiment adopts chitosan hydrogel induction in situ method to synthesize superparamagnetic nano-ferric oxide particles, the steps of the method are as follows: one, chitosan powder is added in the acetic acid solution, mechanically stirred Dissolve completely to chitosan, be mixed with the light yellow chitosan solution that mass percent concentration is 2~5% homogeneity; Let stand for 8-12 hours to obtain chitosan gel; 3. Soak chitosan gel in 0.06mol / L FeCl 3 aqueous solution, water, 0.03mol / L Fe(NO 3 ) 2 aqueous solution, water, and soaking cycle three to five times, that is, the formation of chitosan hydrogel (CS-NH 2 ---Fe 2+ , Fe 3+ ); Four, immerse the aqueous solution of the chitosan hydrogel that contains iron ion to carry out alkalization treatment 5~24h, wherein NaOH mass percent concentration is 4%, adopt distilled water to rinse the magnetic chitosan hydrogel of black to medium then 5. Add the black magnetic chitosan g...

specific Embodiment approach 2

[0012] Specific embodiment two: what this embodiment is different from specific embodiment one is that in step five, the magnetic chitosan gel after step four rinsing will be added to H 2 o 2 or lysozyme solution for degradation reaction; where H 2 o 2 The volume percent concentration of the solution is 4%, and the mass percent concentration of the lysozyme solution is 0.015%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiments 1 and 2 is that in step 2, the cross-linking agent is a physical cross-linking agent, and the physical cross-linking agent is tripolyphosphate, glycerophosphate or glycerol. Other steps are the same as those in Embodiments 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com