Process for the preparation of antimicrobial mould inhibitor

A technology of antibacterial and antifungal agents and adhesives, which is applied in the field of preparation of antibacterial and antifungal agents, can solve the problems of chitosan’s bactericidal and antibacterial performance reduction, composite film’s unsatisfactory bactericidal ability, limited application range, etc., and achieve good sterilization and antifungal properties. Mildew effect, good timeliness, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: 0.1g hydroxypropyl ethyl cellulose is dissolved in 10g hydrochloric acid, then add 1g particle diameter and be less than 100nm German production P25 type nano-titanium dioxide, after mixing, add 10ml glutaraldehyde, stir, rotating speed 20 revs / min, exchange The joint reaction was carried out for 0.5 hours at a temperature of 80°C. After cross-linking, let it stand for defoaming, apply a film, and get a new type of antibacterial and antifungal agent after air-drying. Spread the bacterial liquid evenly on the glass slide coated with a new antibacterial and antifungal agent, after 0, 2, 4, 8, 12, and 24 hours, gently wipe the bacterial liquid with a cotton swab and place it in normal saline. Oscillate, take 0.3ml in the petri dish, pour into the culture medium, cultivate in the incubator for 48 hours, take out the number of colonies, the sterilization rate is respectively 90%, 95%, 98%, 98%, 98%.

Embodiment 2

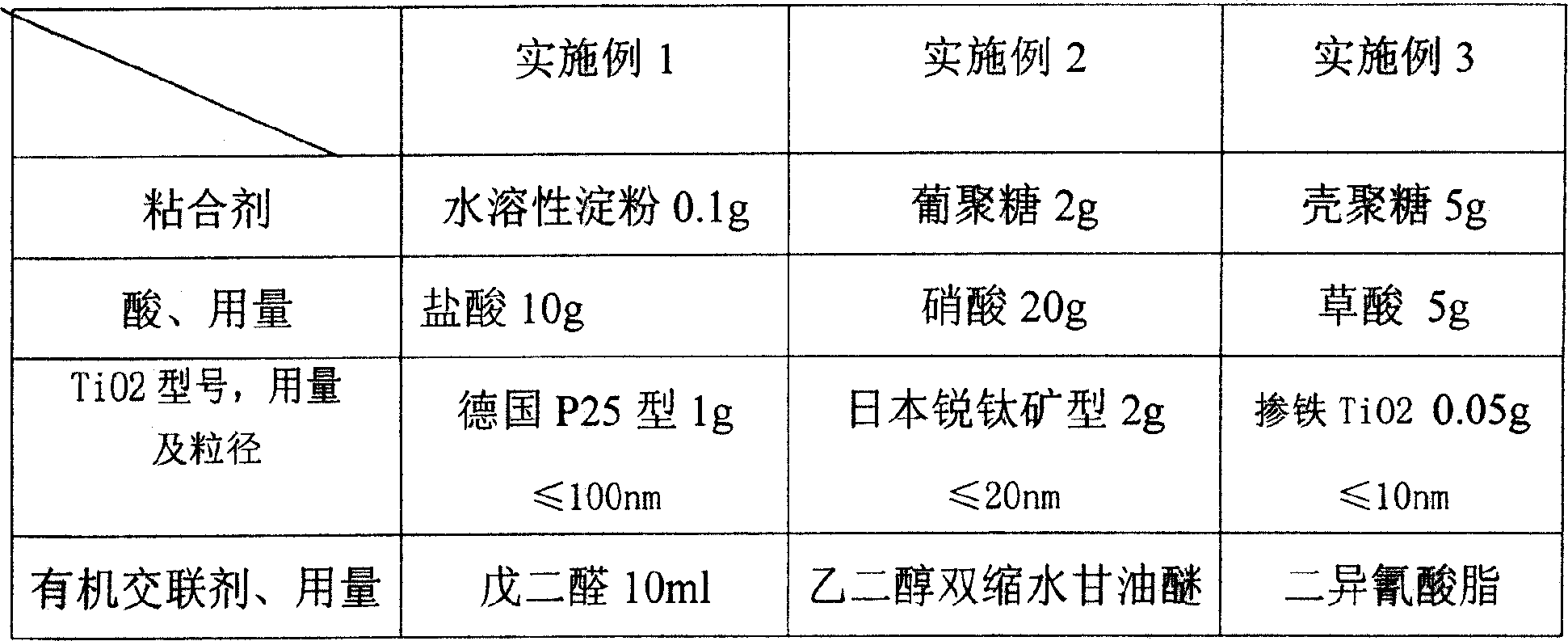

[0026] The operating method of embodiment 2 and embodiment 3 is the same as embodiment 1, and the operating parameters are shown in table 1.

Embodiment 4

[0027] Embodiment 4: Dissolve 0.1g carboxymethyl chitosan in 10g nitric acid, add 0.01g ethyl cellulose, add 1g particle diameter and be less than 20nm Japanese nano titanium dioxide after mixing for 12 hours, add 10ml ethylene glycol after mixing Bis-glycidyl glycidyl ether, stirred at a speed of 20 rpm, crosslinked for 0.5 hours, at a temperature of 80°C. After cross-linking, let it stand for defoaming, apply a film, and get a new type of antibacterial and antifungal agent after air-drying. Spread the bacterial liquid evenly on the glass slide coated with a new antibacterial and antifungal agent, after 0, 2, 4, 8, 12, and 24 hours, gently wipe the bacterial liquid with a cotton swab and place it in normal saline. Oscillate, get 0.3ml in the petri dish, pour into the medium, cultivate in the incubator for 48 hours, take out the number of colonies, the sterilization rate is respectively 96%, 98%, 99%, 99%, 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com