Magnesium metal reduction process using liquid calcium as reducing agent and device thereof

A reducing agent and metal magnesium technology, applied in the field of non-ferrous metal smelting, can solve the problems of long production cycle, high cost, intermittent production, etc., and achieve the effect of reducing the floor area of the plant, reducing the one-time investment and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

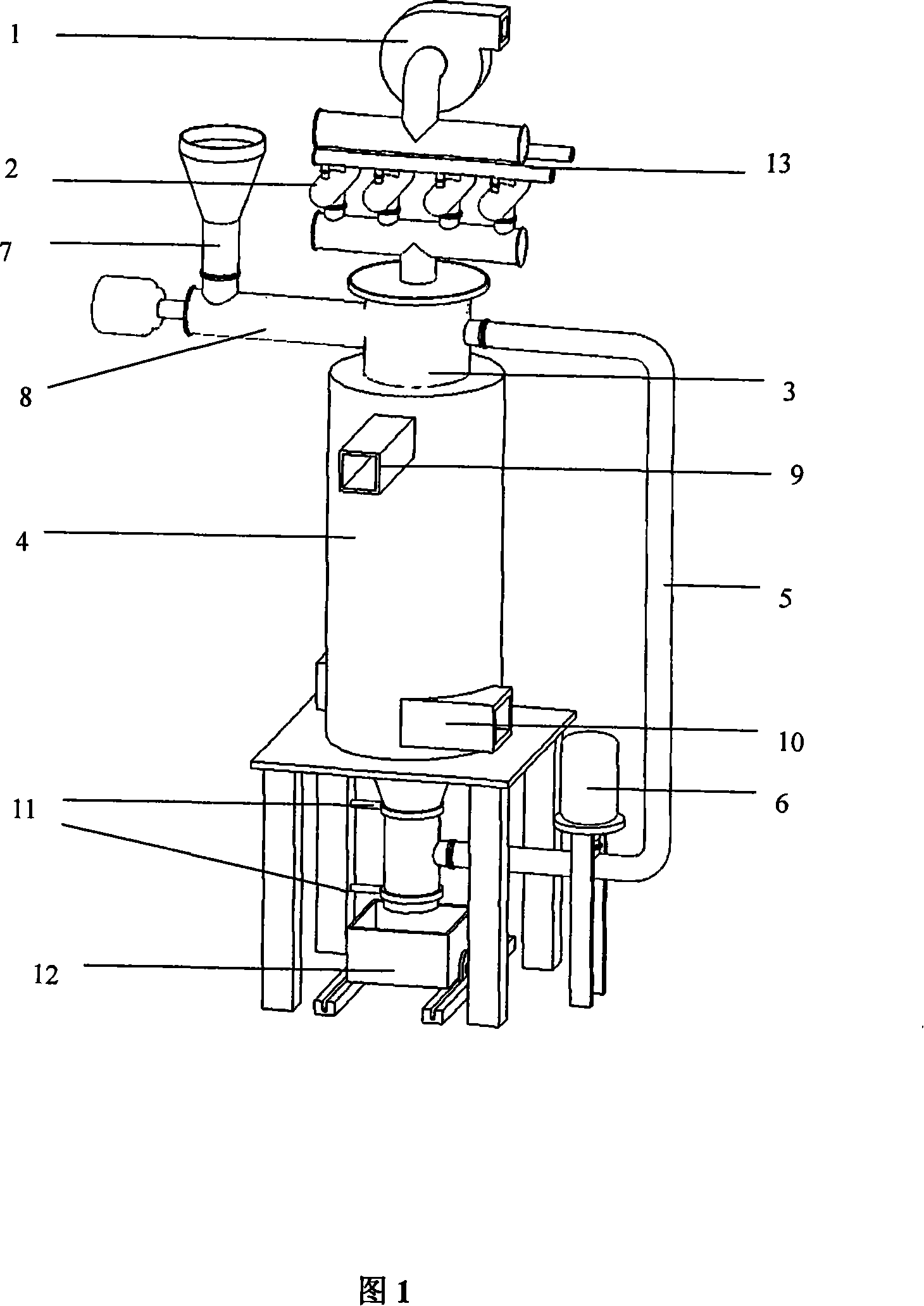

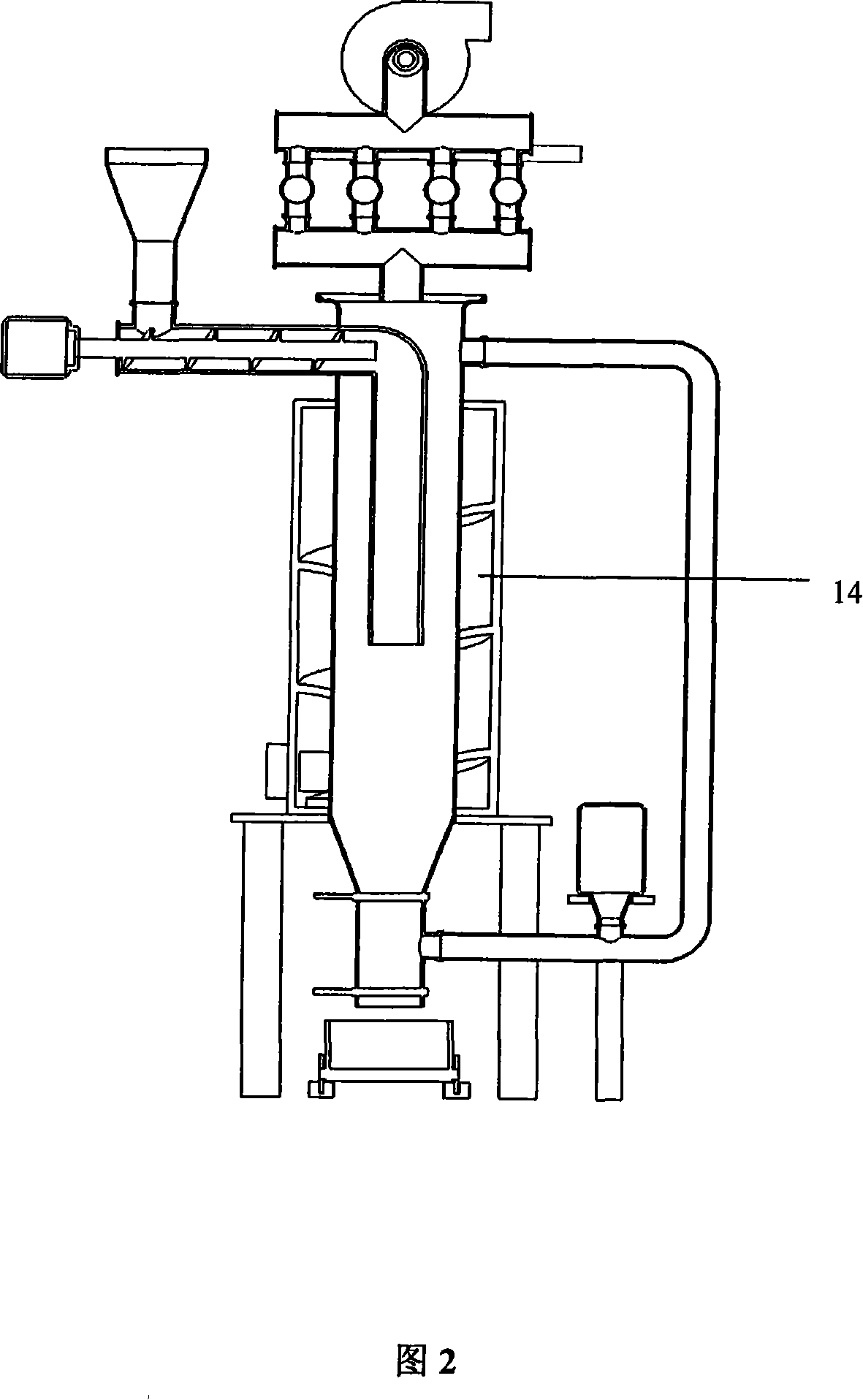

[0018] 1. A metal magnesium reduction process using liquid calcium as a reducing agent. First add solid calcium to the reactor and heat it to melt, the amount of addition ensures that the volume of molten calcium accounts for 1 / 3 of the reactor volume; then, mix the solid calcium and magnesium oxide powder in a ratio of 2:1 and send into the reactor, and the material is immersed in liquid calcium; when the temperature reaches 1090°C, the reaction starts, and magnesium vapor is generated. Group.

[0019] 2. A metal magnesium reduction process using liquid calcium as a reducing agent. First add solid calcium to the reactor and heat it to melt, the amount of addition ensures that the volume of molten calcium accounts for 1 / 3 of the reactor volume; then, mix the solid calcium and magnesium oxide powder in a ratio of 2:1 and send into the reactor, and the material is immersed in liquid calcium; when the temperature reaches 1090°C, the reaction starts, and magnesium vapor is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com