Denitrifying phosphorus-removing carrier and use

A denitrification and phosphorus removal, carrier technology, applied in silicate, inorganic chemistry, adsorbed water/sewage treatment, etc., can solve the problem that the concentration range of denitrification and phosphorus removal is not indicated, the nitrogen and phosphorus removal effect is difficult to stabilize, and the patent disclosure is insufficient. and other problems, to achieve good economic benefits, low cost of raw materials, and improve the effect of contact surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A nitrogen and phosphorus removal carrier, the components by weight are as follows:

[0067] Based on the dry basis of the finished product as 200kg:

[0068] Clinoptilolite powder (90% through 100 mesh exchange capacity above 100cmol(+) / kg) 100kg

[0069] Gypsum powder (90% over 100 mesh) 70kg

[0070] Industrial salt (particle size 2-3cm) 10kg

[0071] Ordinary Portland cement (label 425) 20kg

[0072] Pine sawdust 2kg

[0073] Add 200kg of clean water.

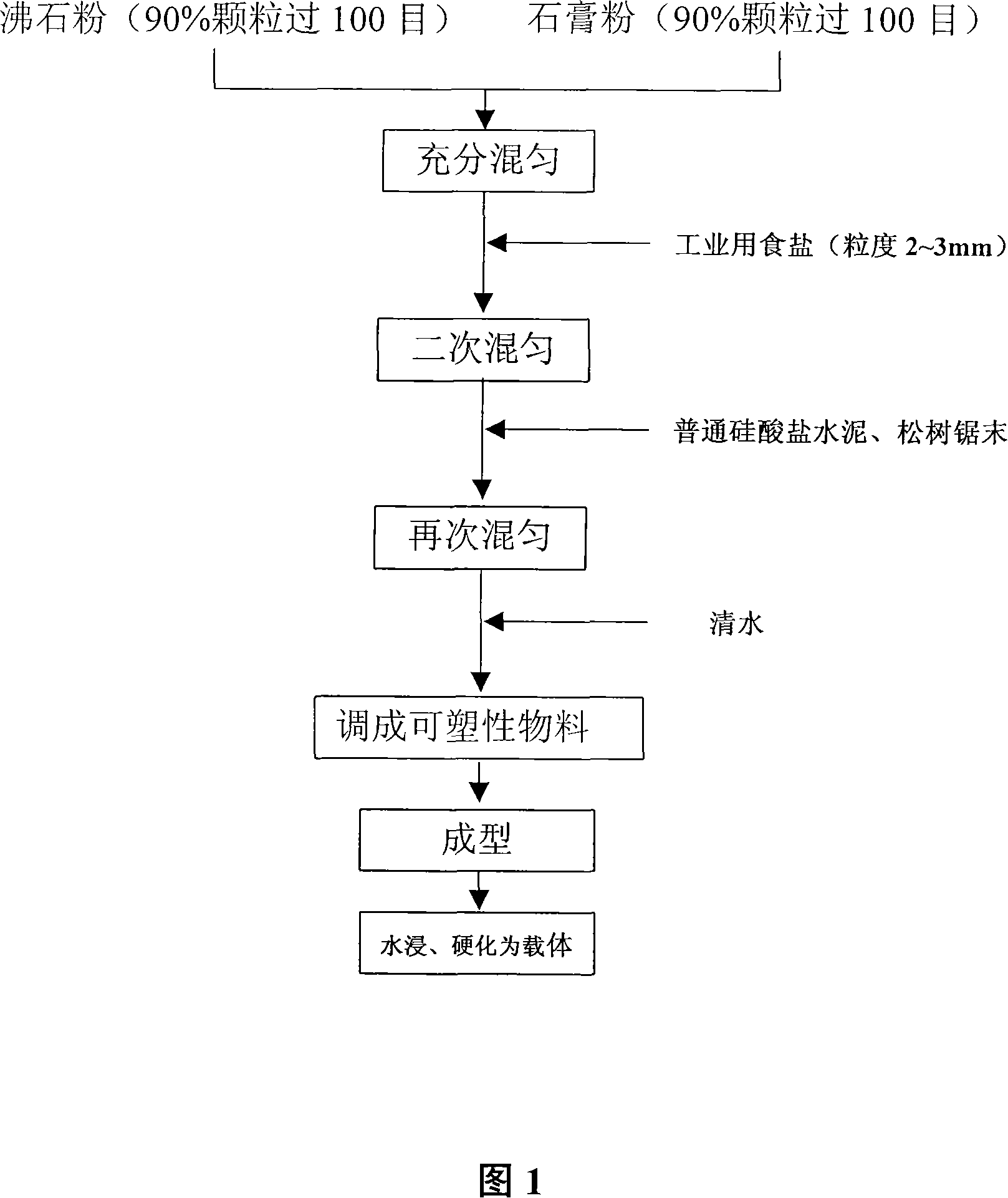

[0074] Prepare as follows:

[0075] 1) According to the formula, mix clinoptilolite powder and gypsum powder with a powder mixer for 5-10 minutes to obtain material 1;

[0076] 2) Under stirring conditions, add industrial salt, ordinary portland cement, and pine sawdust to material 1, and continue mixing, subject to the fact that there is no sign of unmixed material with the naked eye, to obtain material 2;

[0077] 3) Spray the material 2 obtained in step 2) with clear water under stirring, and observe the pl...

Embodiment 2

[0083] According to the preparation method of the embodiment, the present embodiment is another optimized formula wherein, the components by weight are as follows:

[0084] Clinoptilolite powder (90% through 100 mesh exchange capacity above 100cmol(+) / kg) 110kg

[0085] Gypsum powder (90% over 100 mesh) 60kg

[0086] Industrial salt (particle size 2-3cm) 10kg

[0087] Ordinary Portland cement (label 325) 20kg

[0088] Pine sawdust 2kg

[0089] Add 150kg of clean water.

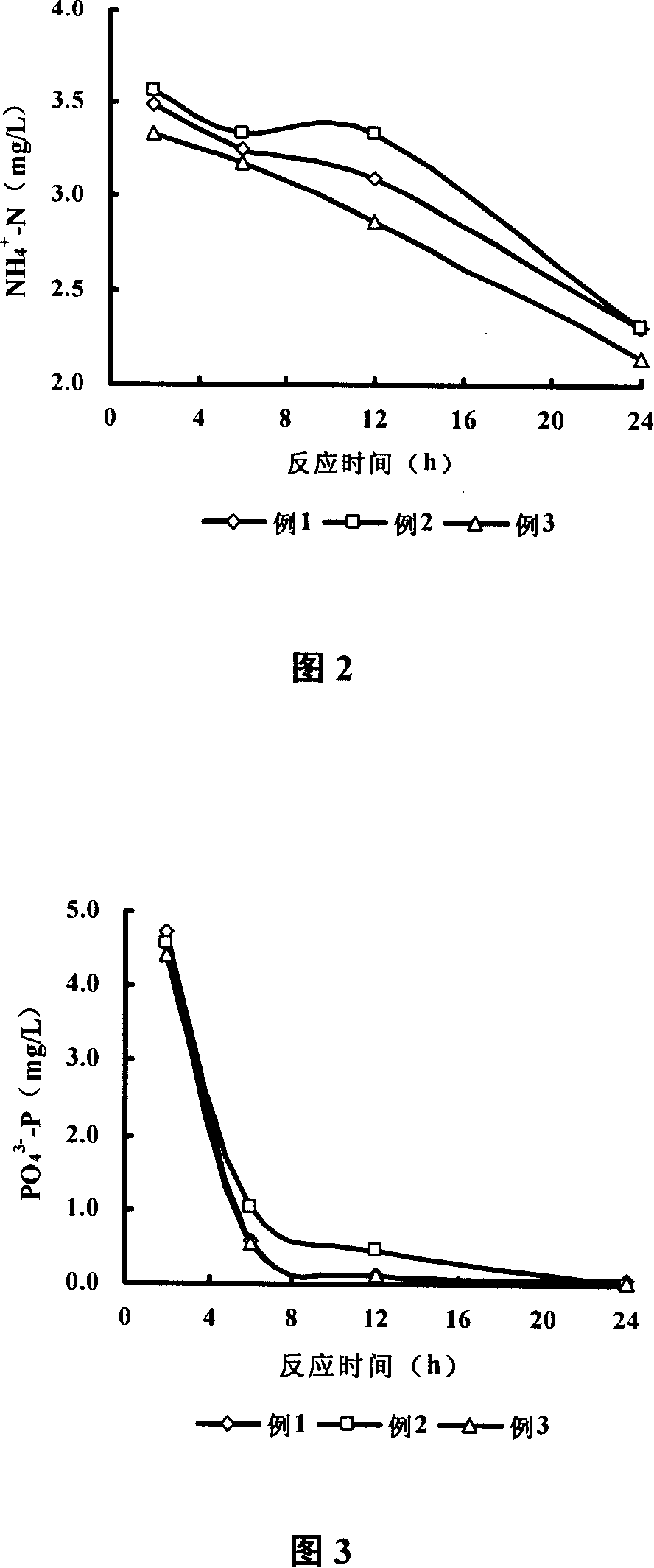

[0090] The denitrification and phosphorus removal carrier prepared in this example has a first-order reaction rate constant of 0.0197h in the denitrification process -1 , the half-life is 35h; the first-order reaction rate constant of phosphorus removal process is 0.3395h -1 , with a half-life of 2h.

Embodiment 3

[0092]The present embodiment is the best implementation mode of the present invention, according to the preparation method of embodiment, its formula by weight component is as follows:

[0093] Based on the dry basis of the finished product as 200kg:

[0094] Clinoptilolite powder (90% through 100 mesh exchange capacity above 100cmol(+) / kg) 120kg

[0095] Gypsum powder (90% over 100 mesh) 50kg

[0096] Industrial salt particle size (2-3cm) 10kg

[0097] Ordinary Portland cement (label 525) 20kg

[0098] Pine sawdust 2kg

[0099] Add 100kg of clean water.

[0100] The denitrification and phosphorus removal carrier prepared in this example has a first-order reaction rate constant of 0.0205h in the denitrification process -1 , the half-life is 34h; the first-order reaction rate constant of phosphorus removal process is 0.2191h -1 , with a half-life of 3h.

[0101] According to the technical solutions and examples provided by the present invention, the nitrogen and phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com