Method for preparing molecule cage type starch

A molecular cage and starch technology, applied in the field of starch preparation, can solve the problems of easy collapse, complex production process and high production cost, and achieve the effects of improving food quality, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

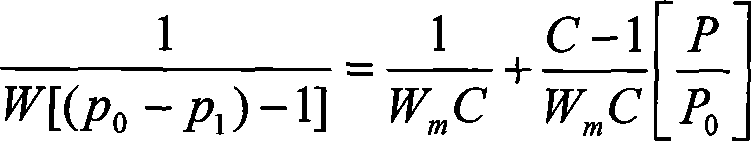

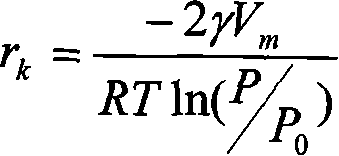

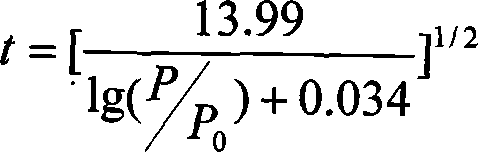

[0010] Specific embodiment one: the molecular cage starch of this embodiment is prepared according to the following steps: one, prepare starch paste with starch and ethanol with a moisture content of <1%, wherein the mass ratio of starch and ethanol is 7-12:28; two, ball milling Starch paste: the quantity ratio of large balls, medium balls and small balls is 1:4:2, the mass ratio of balls to material is 5-6:1, the speed of the ball mill is 100-300r / min, and the milling time is 20-30h; 3. Dried and pulverized to obtain non-crystallized starch; 4. Dissolve sodium trimetaphosphate with 5% to 8% mass of non-crystallized starch in water, add non-crystallized starch and adjust pH with 5% sodium hydroxide solution The value is 7~11, then put it in the environment of 20~50°C for 2.0~4.0h, and then filter after neutralizing the pH value of the system. Crystallized starch; 5. Add water 10-20 times the weight of cross-linked amorphous starch to cross-linked amorphous starch, gelatinize a...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the starch in step 1 is cornstarch. Other steps and parameters are the same as those in Embodiment 1.

[0016] The moisture content of starch > 1% can be evaporated by drying.

[0017] Since the molecular cage corn starch uses the network structure characteristics of the corn starch molecule itself and introduces functional groups, the inherent molecular structure is further stabilized, and it has stable performance, acid resistance stability and thermal stability. The acid-resistant stability and heat-resistant stability of starch can be judged by the change of the viscosity value of starch paste. The smaller the viscosity difference, the higher the heat-resistant stability and acid-resistant stability of starch. The viscosity difference of porous starch measured by Brabender viscometer before and after holding at 95°C for half an hour is 4.52Pa·s, while the viscosity difference of molecular...

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, the diameter ratio of the large ball, the medium ball, and the small ball is 4:2:1. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com