Limestone activity test method and test device for wet process of FGD

A testing method and testing device technology, which can be used in measurement devices, chemical method analysis, special data processing applications, etc., can solve the problems of difficult control and measurement of gas flow, complicated operation, and huge experimental system, and achieve rapid and accurate reaction activity, The effect of stable chemical properties and simple test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

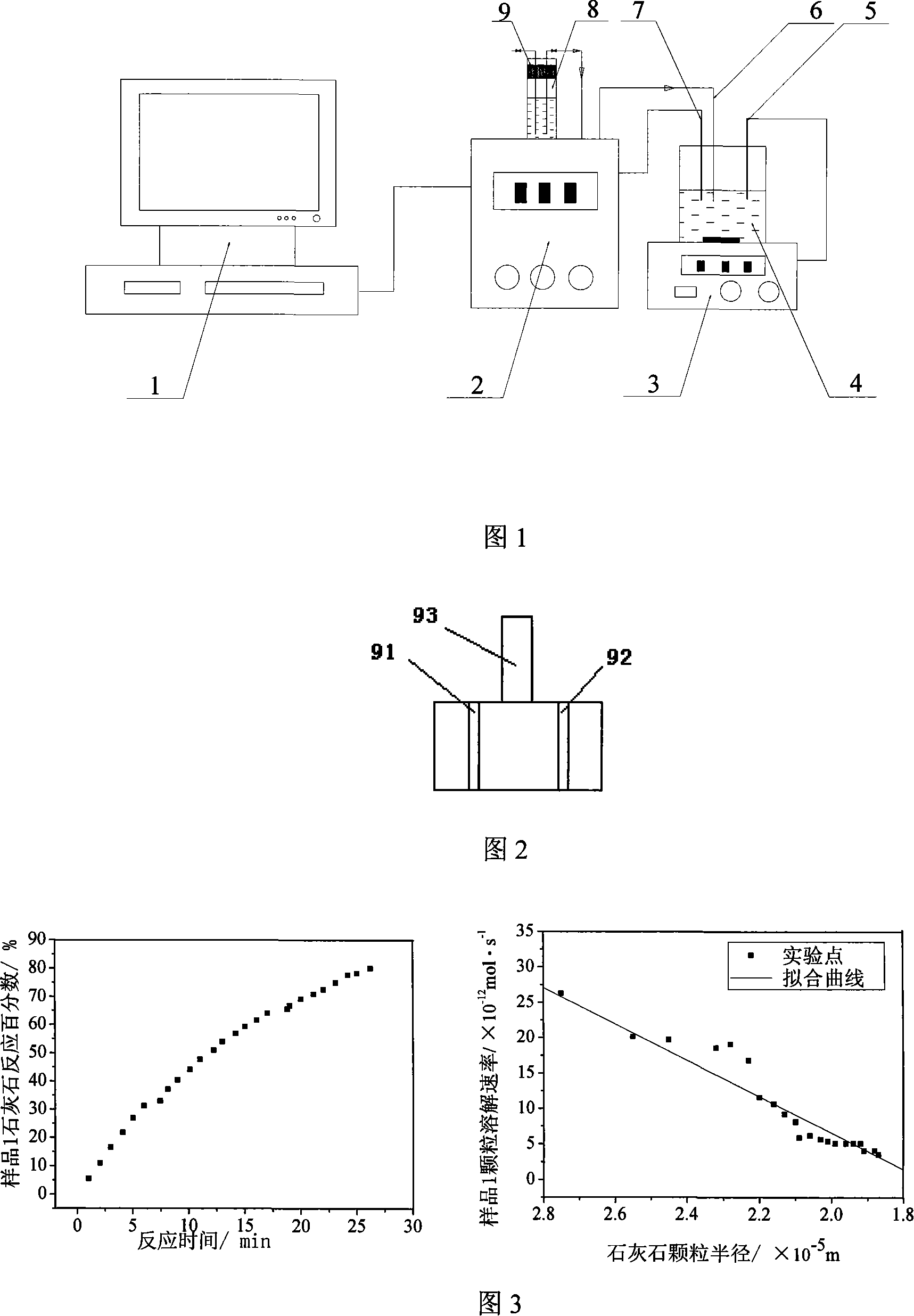

Method used

Image

Examples

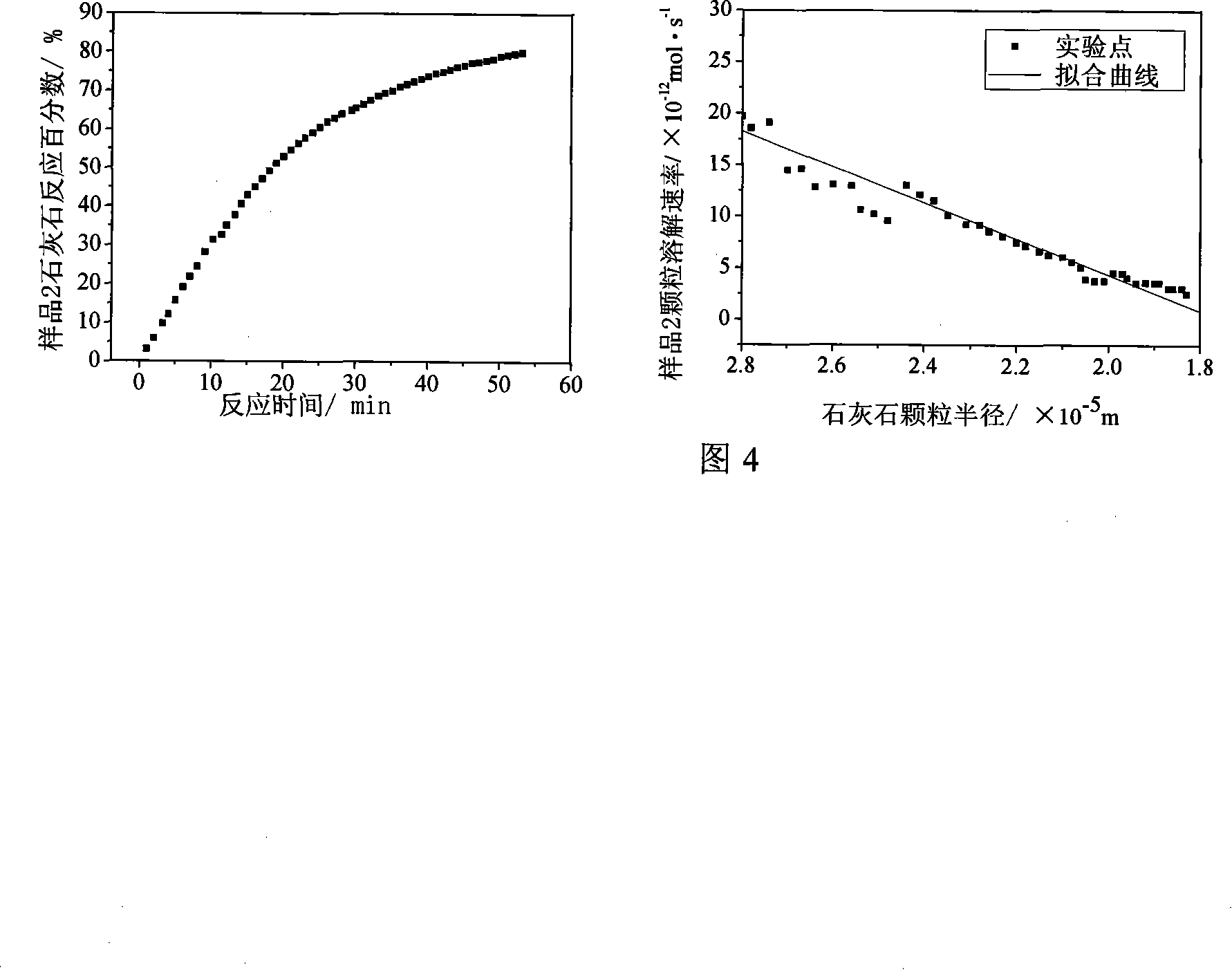

Embodiment 1

[0064] (1) Limestone sample 1 was processed into 250-270 mesh limestone powder (average particle size: 0.058mm), and stored in a desiccating dish filled with color-changing silica gel.

[0065] (2) CaCO in limestone sample 1# 3 Content is 92.68%, MgCO 3 The content is 1.20%.

[0066] (3) Utilize gas cylinder and mass flow meter to displace 12.8g of SO 2Dissolve in a certain amount of ethanol, and set the volume to 2L, the configured SO 2 The concentration of the ethanol solution is 0.1mol / L, and the configured acid reagent is stored in the acid reagent bottle.

[0067] (4) Prepare 0.1mol / L calcium chloride solution; measure about 250ml of calcium chloride solution and pour it into a 500ml beaker.

[0068] (5) Place the beaker on a constant temperature stirrer, control the temperature at 50±1°C, and the magnetic stirring speed is 800r / min;

[0069] (6) Weigh 150 mg of limestone powder and add it to a beaker, and stir for 5 minutes to form a limestone suspension.

[0070] ...

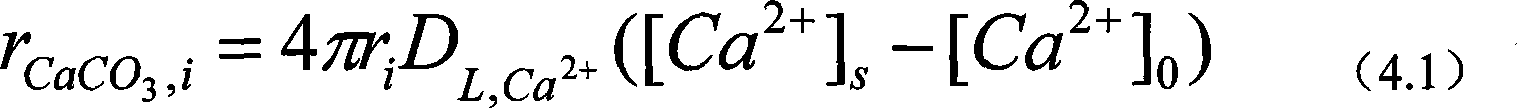

Embodiment 2

[0073] (1) Limestone sample 2# is processed into 250-270 mesh limestone powder, and then stored in a drying dish equipped with color-changing silica gel.

[0074] (2) The content of CaCO3 in limestone sample 2# is 91.30%, and the content of MgCO3 is 4.33%.

[0075] (3) Utilize gas cylinder and mass flow meter to displace 12.8g of SO 2 Dissolve in a certain amount of ethanol, and set the volume to 2L, the configured SO 2 The concentration of the ethanol solution is 0.1mol / L, and the configured acid reagent is stored in the acid reagent bottle.

[0076] (4) Prepare about 0.1mol / L calcium chloride solution; measure about 250ml of calcium chloride solution and pour it into a 500ml beaker.

[0077] (5) Place the beaker on a constant temperature stirrer, control the temperature at 50±1°C, and the magnetic stirring speed is 800r / min;

[0078] (6) Weigh 150 mg of limestone powder and add it to a beaker, and stir for 5 minutes to form a limestone suspension.

[0079] (7) Put the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com