Cladding gain guided microstructure hollow optical fiber

A hollow-core optical fiber and microstructure technology, applied in clad optical fiber, multi-layer core/clad optical fiber, optical waveguide and light guide, etc., can solve problems such as development constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

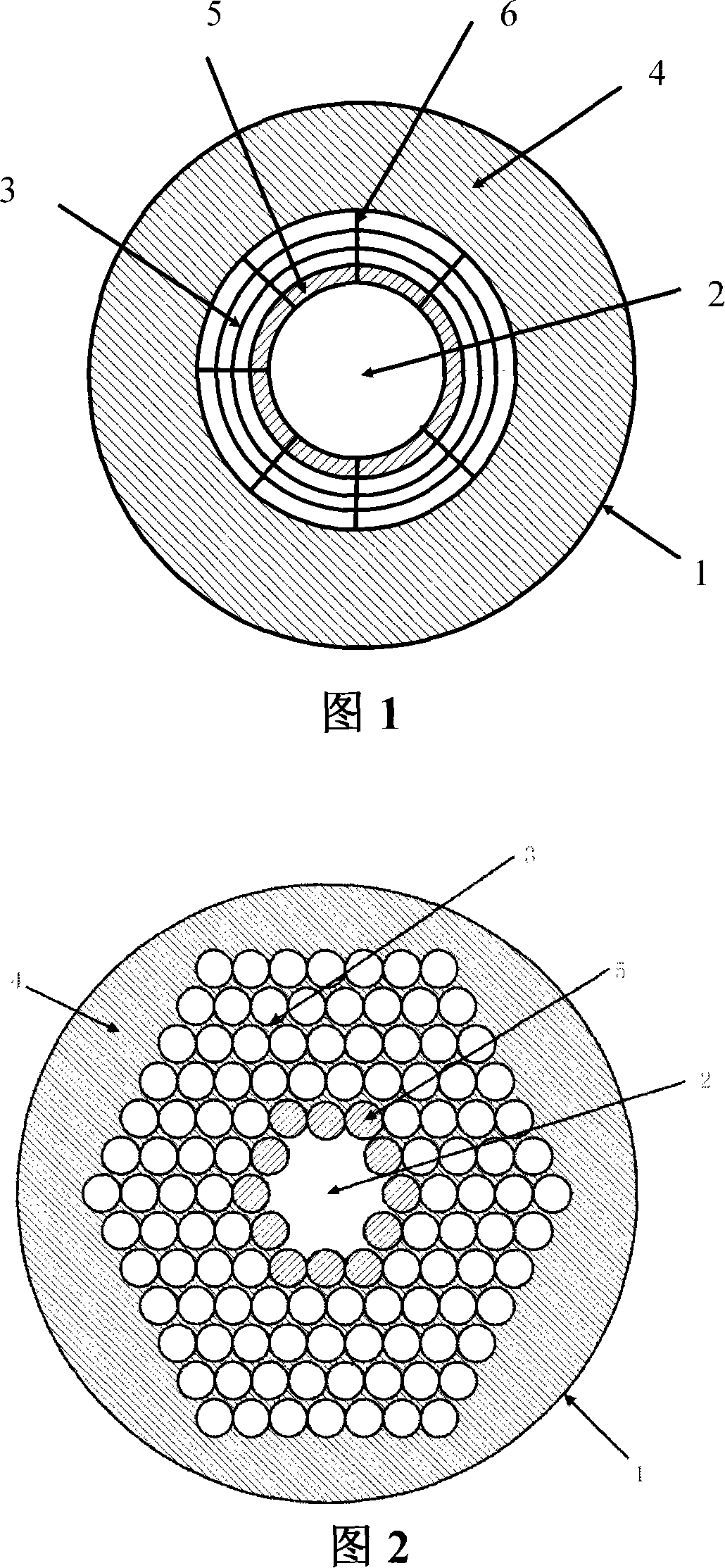

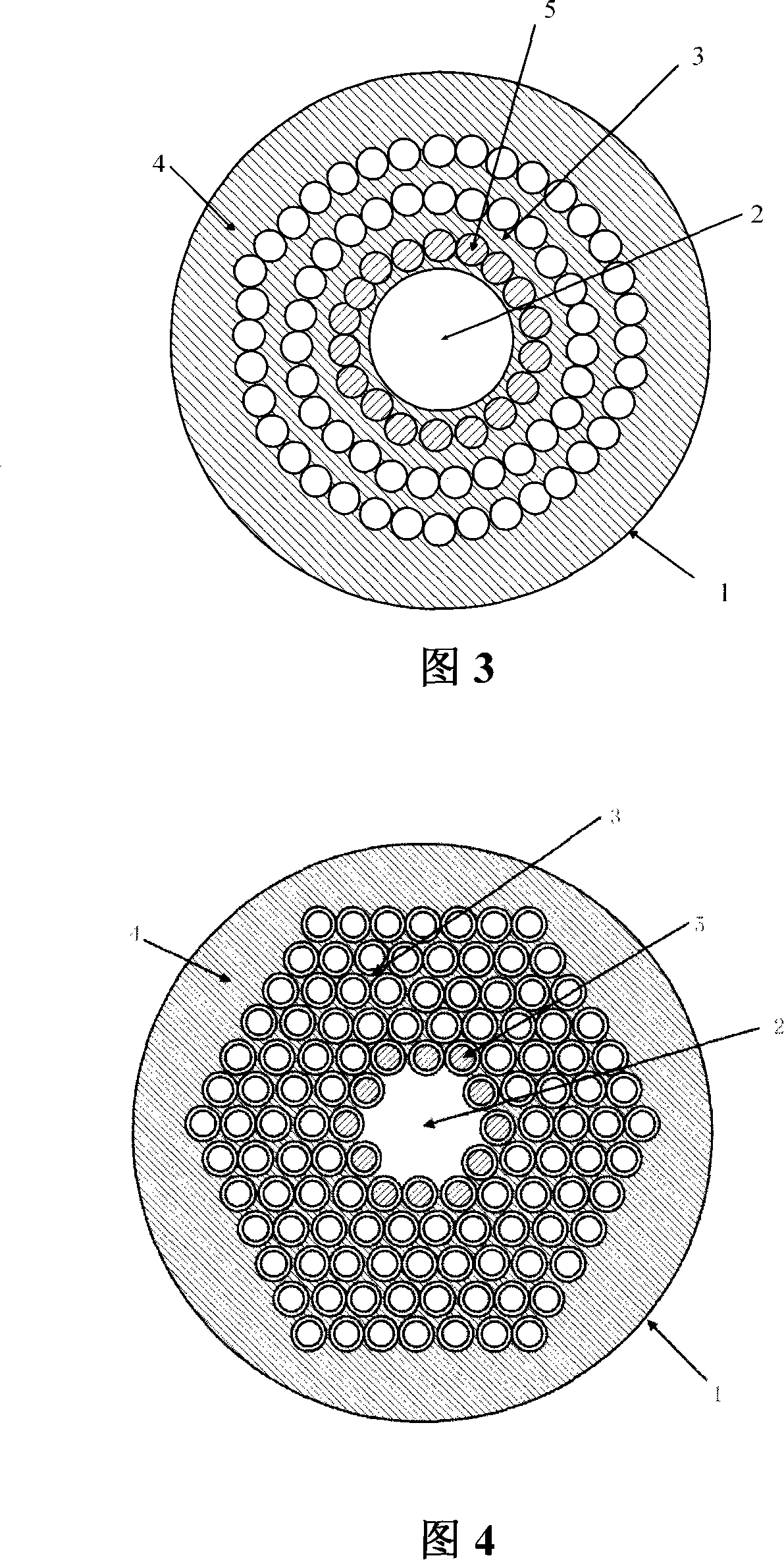

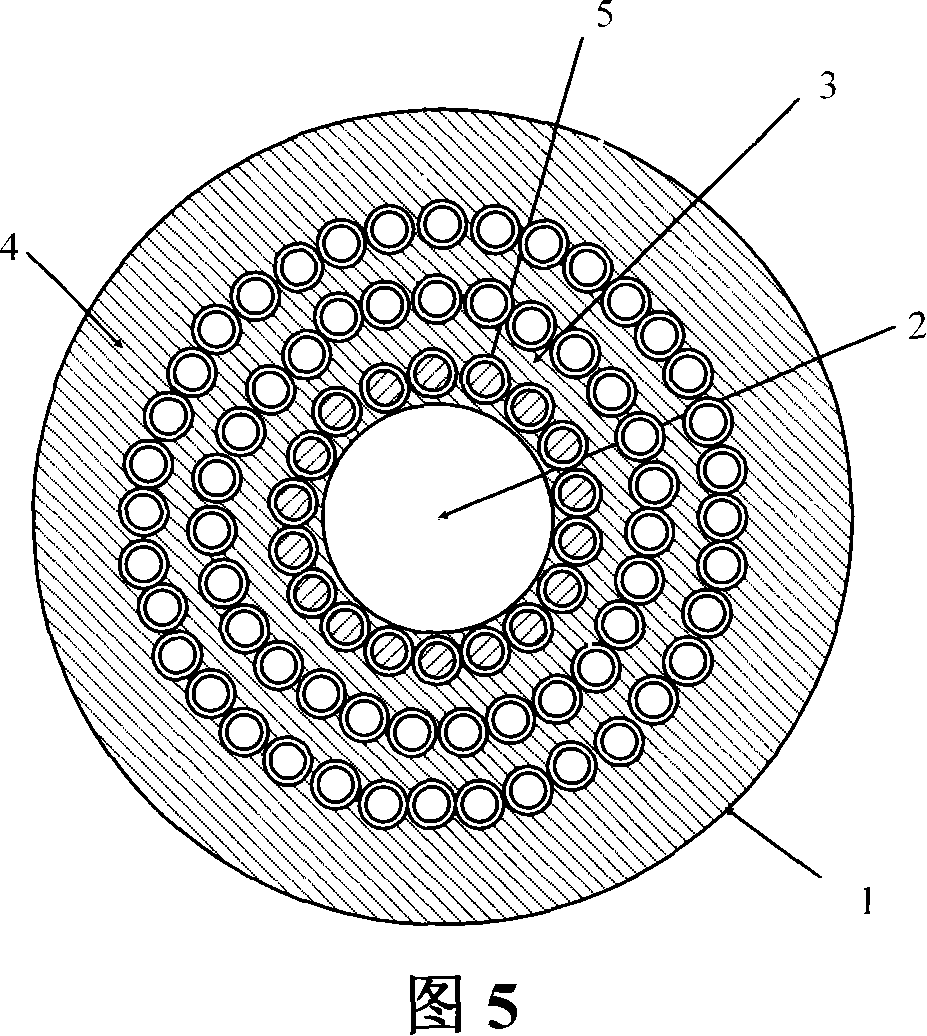

[0024] FIG. 1 is a schematic cross-sectional view of an optical fiber according to Embodiment 1 of the present invention. This is a microstructured hollow-core fiber whose inner cladding region 3 has a spider web-like refractive index distribution. This microstructured fiber is made by covering the inner cladding region 3 on the core region 2 and covering the outer cladding region 4 on the inner cladding region 3. become. The core area 2 is a hollow core with a diameter of 10 μm. Between the core area 2 and the outer cladding area 4 is an inner cladding area 3. The inner cladding area 3 has a refractive index distribution similar to a spider web, and the thickness of the support bar 6 is 0.25 μm, the material is quartz glass, the thickness of the air gap between the support bars 6 is 5 μm, and the material of the outer cladding region 4 is quartz glass. Inject the solution of Rhodamine 6G and ethylene glycol into the air gap 5 in the inner cladding region 3 closest to the cor...

Embodiment 2

[0026] The difference between embodiment 2 and embodiment 1 is: in the air gap 5 in the inner cladding region 3 closest to the fiber core region 2, inject a solution with the dye DCM as a solute, the solvent adopts benzyl alcohol and ethylene glycol, and the concentration of the solution is for 10 -2 mol / L, both ends of the fiber are encapsulated.

Embodiment 3

[0028] The difference between embodiment 3 and embodiment 1 is: the air gap 5 in the inner cladding region 3 closest to the core region 2 is injected with odd red (Kiton red, C 27 H 30 N 2 O 7 S 2 ) is the solution of the solute, the solvent adopts ethylene glycol and glycerol, and the concentration of the solution is 10 -2 mol / L, both ends of the fiber are encapsulated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com