Fire resistant anticorrosive paint of organosilicon

A technology of anti-corrosion coatings and high-temperature-resistant fillers, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor corrosion resistance and poor adhesion of paint films, and achieve excellent coating performance, good acid resistance, and simple coating process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

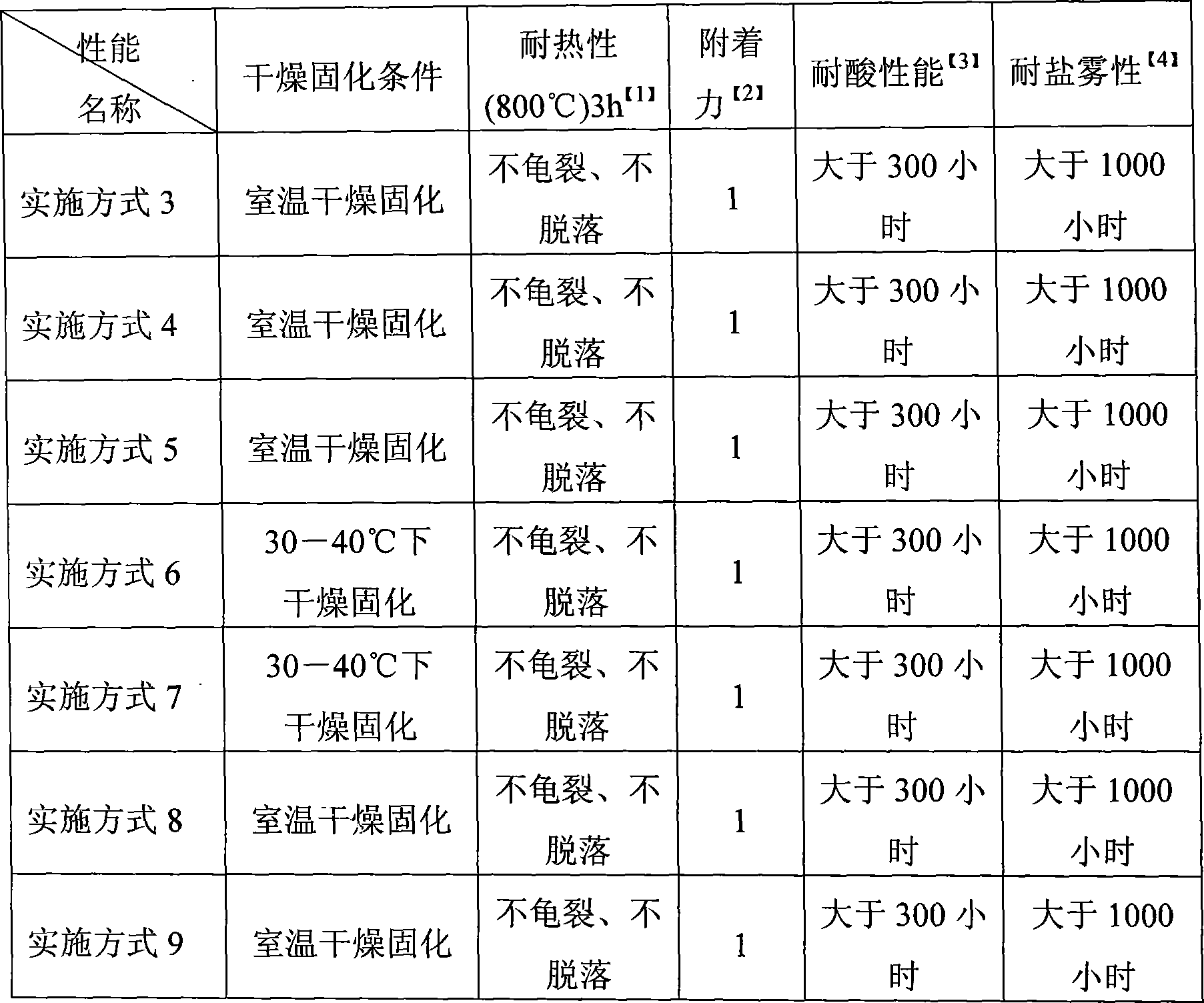

Examples

specific Embodiment approach 1

[0006] Specific Embodiment 1: The organosilicon high temperature resistant anti-corrosion coating of this embodiment consists of 15-40% of organosilicon resin and curing agent, 15-60% of high-temperature resistant filler, 0.01-0.5% of drier, 0.05-0.5% additive, 0.1-5% coupling agent and 1-64% solvent. Wherein the mass ratio of silicone resin and curing agent is 10-14:1, the silicone resin is epoxy modified silicone resin, the curing agent is polyamide, polyamide is polyamide 650, polyamide Amide 651 or polyamide 300#, for curing. The high-temperature-resistant filler is one or a mixture of glass powder, mica powder or talcum powder. When the high-temperature-resistant filler is a mixture, various high-temperature-resistant fillers can be mixed in any ratio; glass powder, mica powder And the particle size of talcum powder is less than 1μm. The drier is octanoate, zinc, cobalt, magnesium, iron or naphthenate, and the octanoate is one or more of zinc octanoate, cobalt octanoate...

specific Embodiment approach 2

[0007] Specific embodiment 2: The organosilicon high temperature resistant anti-corrosion coating of the present embodiment also has the high temperature resistant pigment of 5~25% of total material weight of specific embodiment 1, described high temperature resistant pigment is stainless steel powder or ferrochrome black, The particle size of stainless steel powder or chrome black is 1 μm.

specific Embodiment approach 3

[0008] Specific embodiment three: the organosilicon high temperature resistant anti-corrosion coating of the present embodiment consists of 30% of a mixture of epoxy-modified organosilicon resin and polyamide, 20% of stainless steel powder, 38% of glass powder, 0.2% of chromic anhydride, Zinc caprylate 0.2%, γ-mercaptopropyltriethoxysilane 2.5%, xylene 8%, cyclohexanone 1.1%, wherein the mass ratio of epoxy-modified silicone resin and polyamide is 12:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com