Material for forming film and method for producing film

A film and raw material technology, applied in the direction of metal material coating process, coating, zinc organic compounds, etc., can solve the problems of precursor deterioration, lack of solution, and the volatility of precursor may not be satisfied, and achieve good stability. Good performance, good productivity and good volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Hereinafter, the present invention will be described in more detail through production examples, evaluation examples, and examples. However, the present invention is not limited in any way by the following Examples and the like.

manufacture example

[0051] [Production example] Production of bis(pentane-2,4-diketono)zinc anhydrate

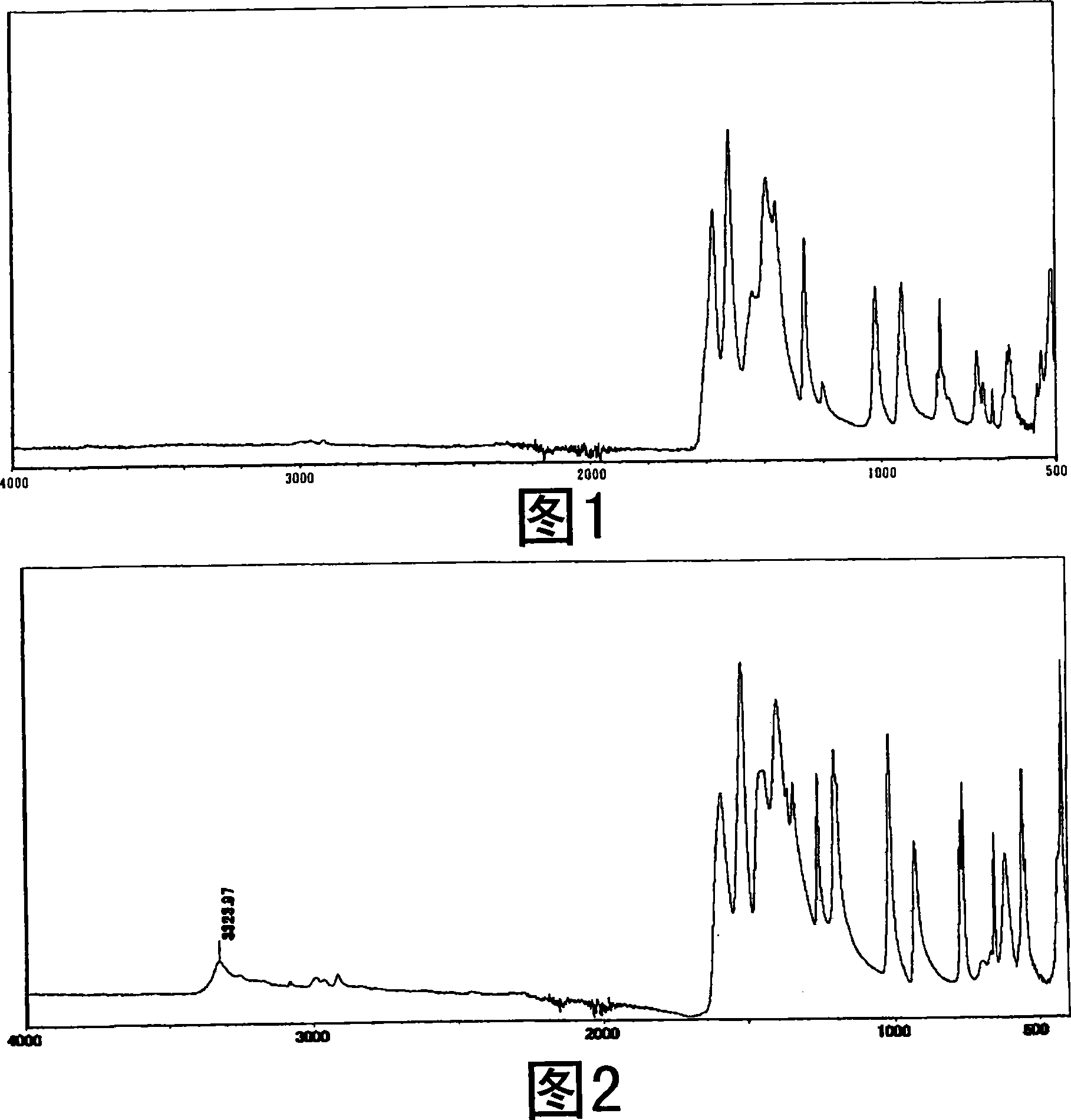

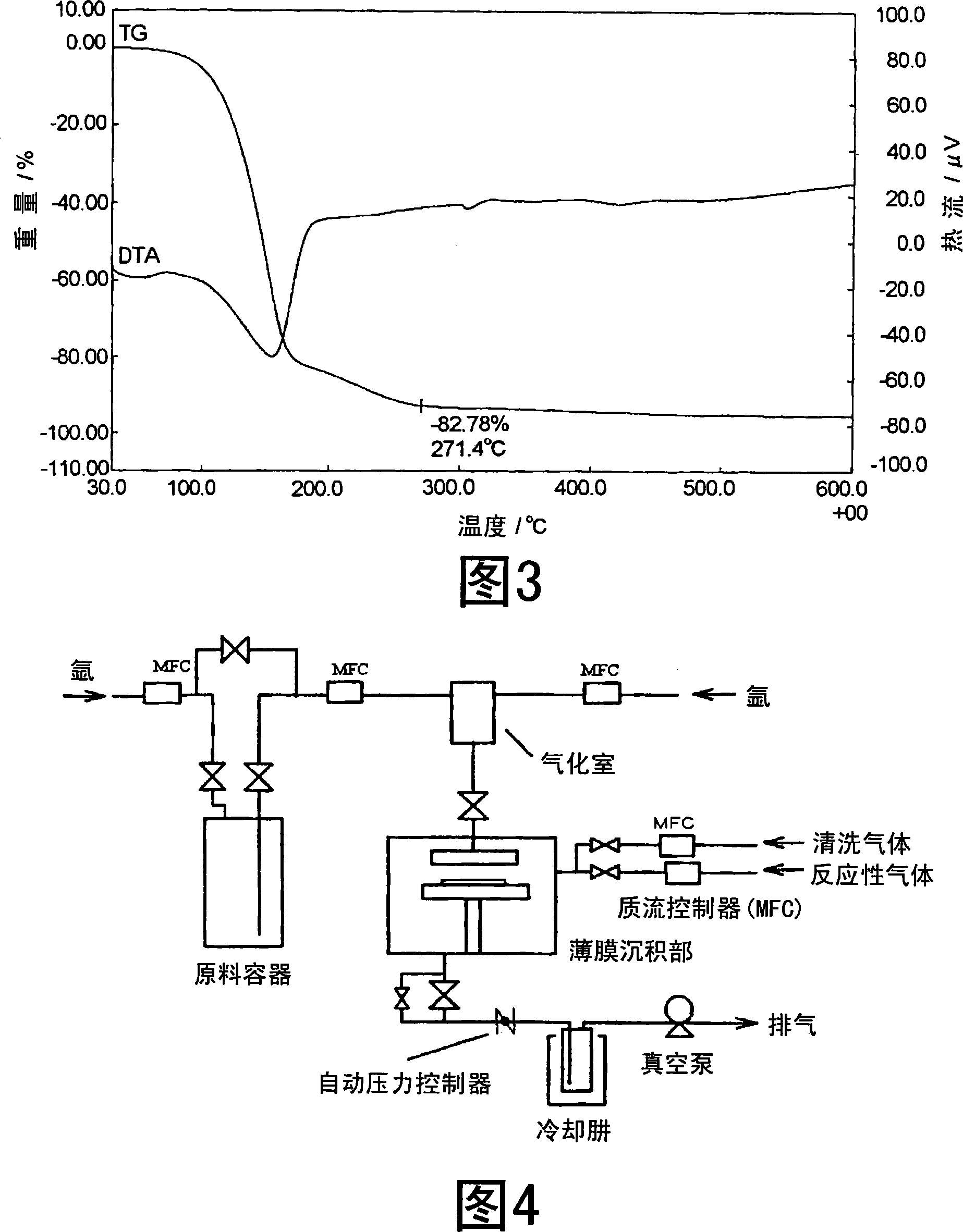

[0052] For commercially available bis(pentane-2,4-diketone)zinc (manufactured by Kanto Chemical Co., Ltd.), the water of hydration was removed by sublimation purification operation under heating and reduced pressure, and the yield obtained from the fraction at 130°C and 30Pa was 60% bis(pentane-2,4-diketonyl)zinc anhydrate. For the obtained crystals, IR, 1 H-NMR, elemental analysis of carbon and hydrogen and TG-DTA, identified as bis(pentane-2,4-diketonyl)zinc anhydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com