Grain graininess and concentration measuring method and device thereof

A measuring device and concentration measurement technology, which is applied in the direction of measuring devices, particle and sedimentation analysis, particle size analysis, etc., can solve problems such as not taking into account, large concentration errors, and inability to obtain measurement results, so as to improve measurement accuracy and reduce measurement errors , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

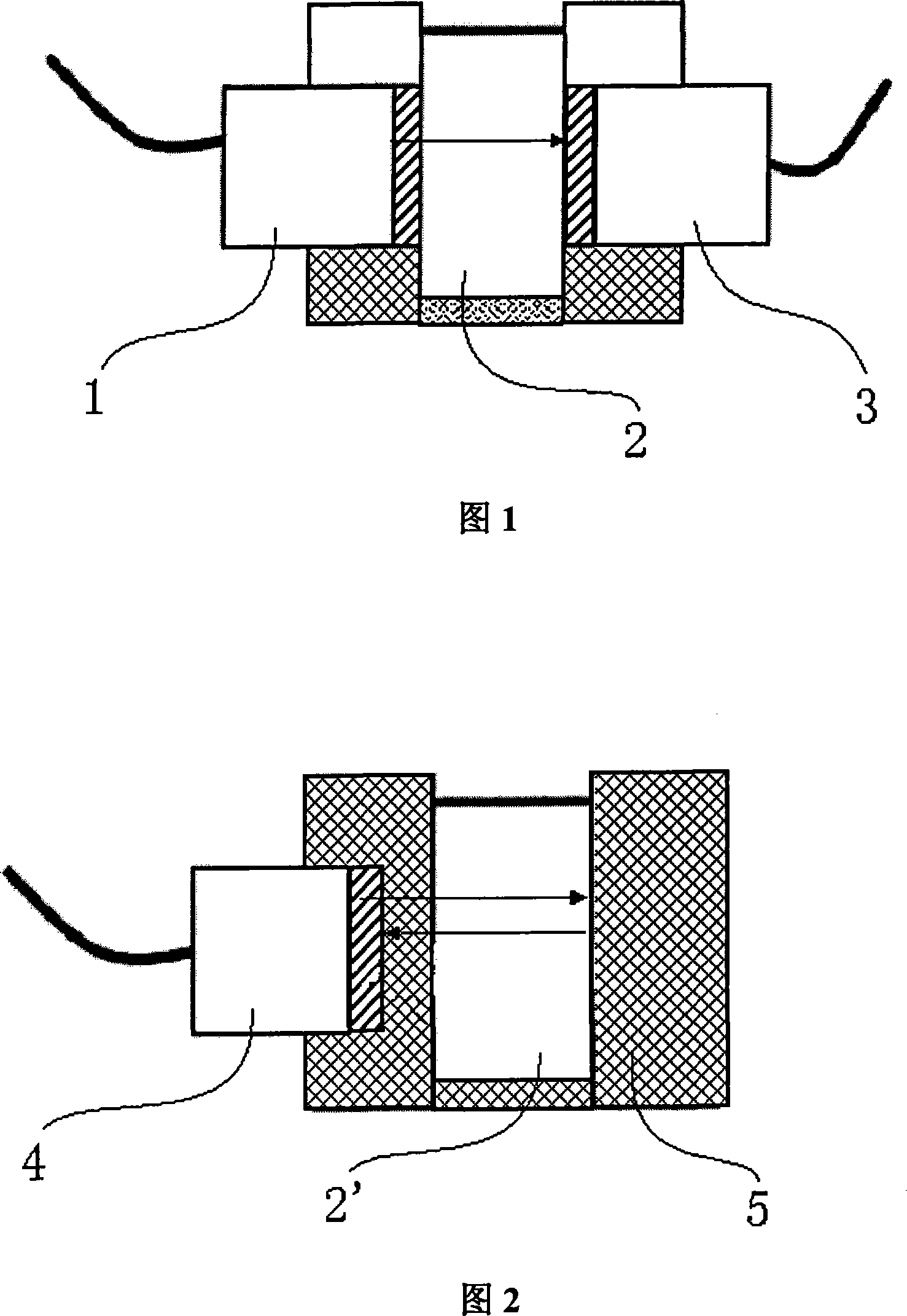

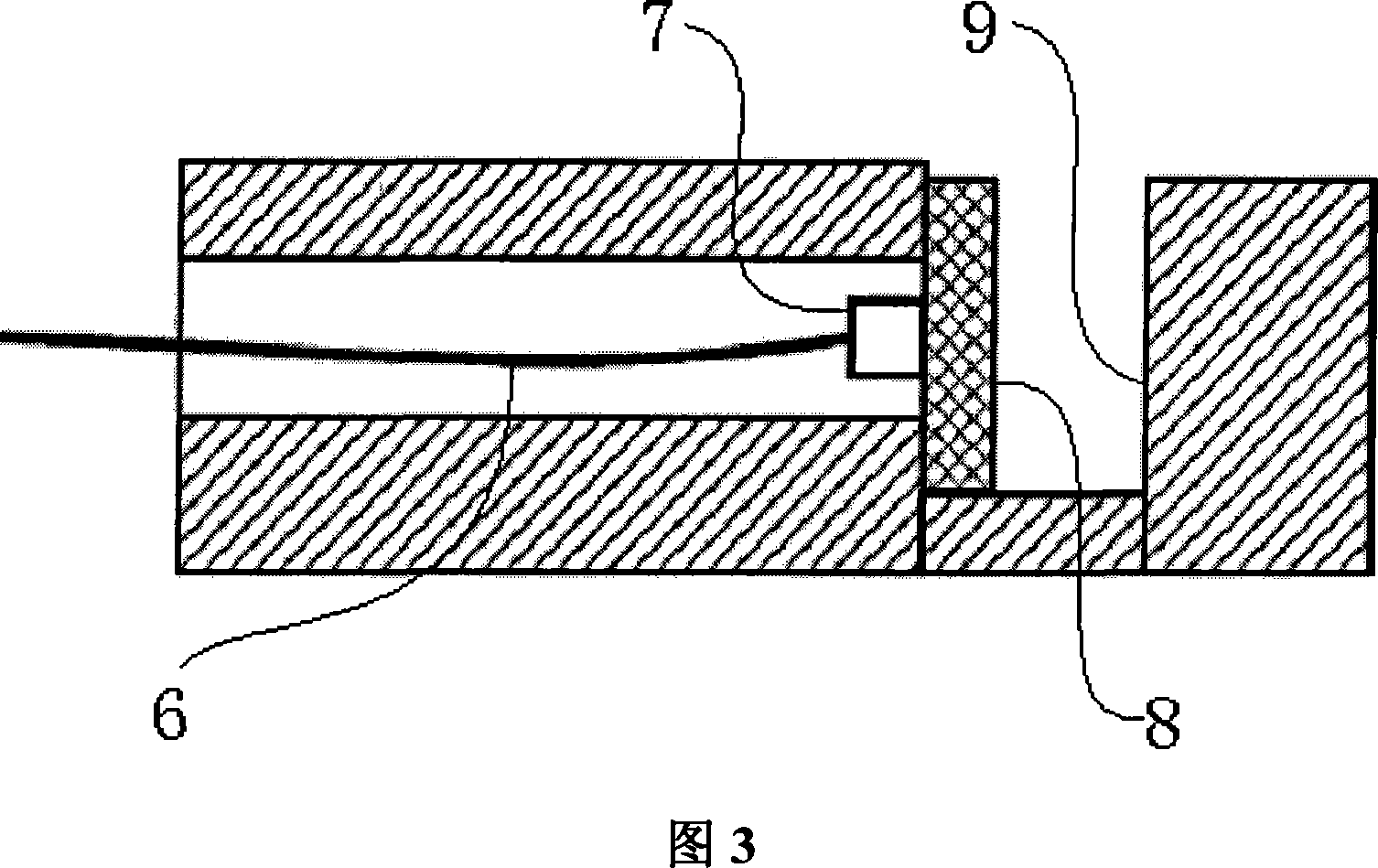

[0029] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods, structures and similar changes of the present invention should be included in the scope of protection of the present invention.

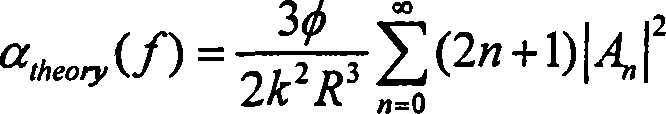

[0030] The present invention considers that the frequency spectrum of sound attenuation or speed (referring to its frequency domain curve with sound frequency) is closely related to particle size, and this relationship can be applied to the particle size measurement of discrete state fully; In the embodiment of the present invention , considering the scattering effect of ultrasonic waves propagating in granular media, calculate the theoretically predicted attenuation spectrum of ultrasonic waves passing through the particle two-phase system;

[0031] α theory ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com