Method for producing magnetic fluid

A magnetic fluid and magnetic nanotechnology, applied in the field of magnetic nanocomplex with high degree, can solve the problems of low saturation magnetization and shedding of ferrite, and achieve the effects of good biocompatibility, not easy to fall off, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

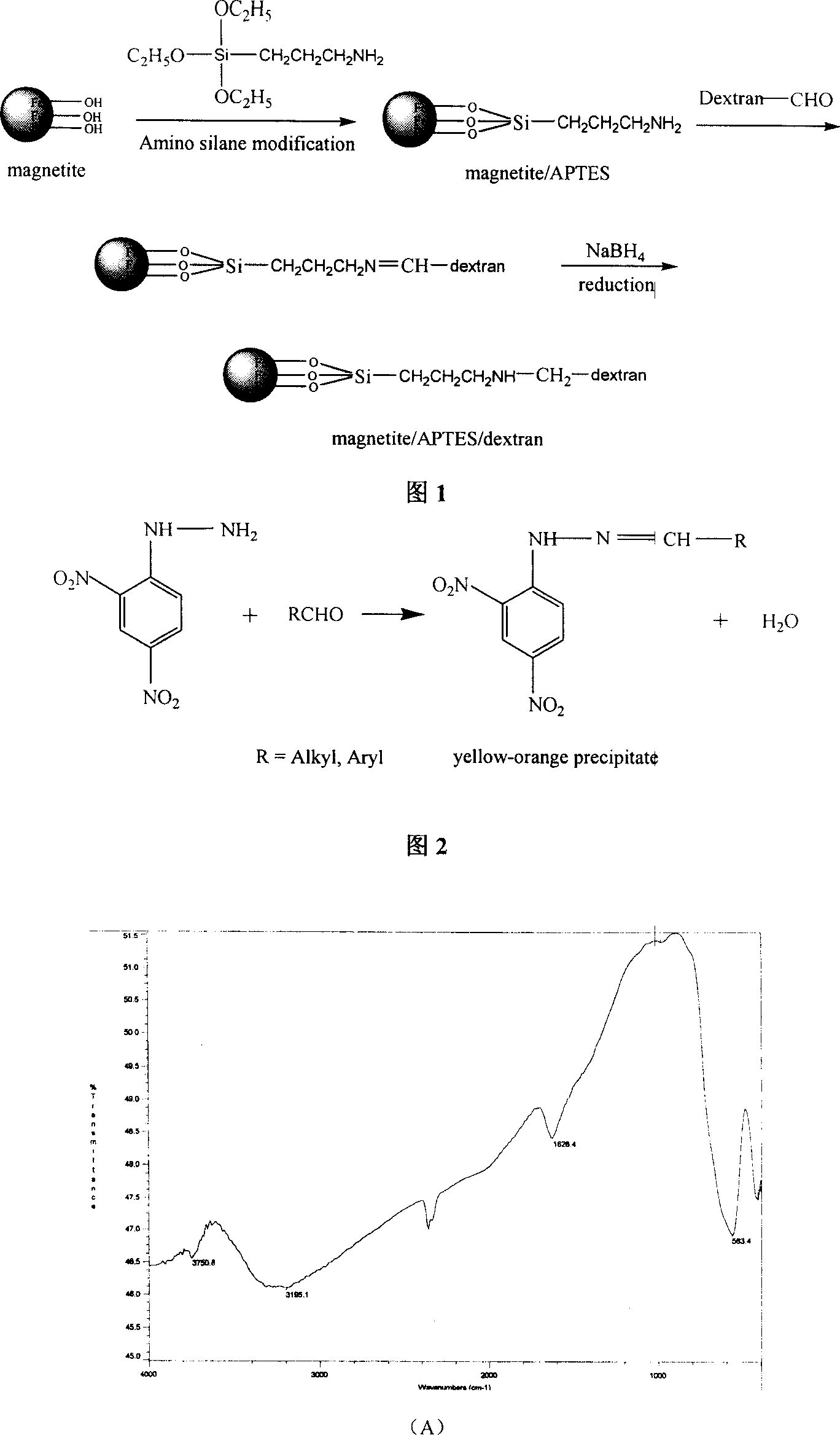

[0021] Typical implementation: dextran oxidation is to dissolve 3.33g dextran in 100mL deionized water, add 8g sodium periodate, stir at room temperature in the dark for 3h, the reaction is completed, deionized water is dialyzed once every 2h, dialyzed five times . After the reaction, the dextran aldehyde was tested with 2,4-dinitrophenylhydrazine, and the oxidation efficiency of dextran was calculated by titration

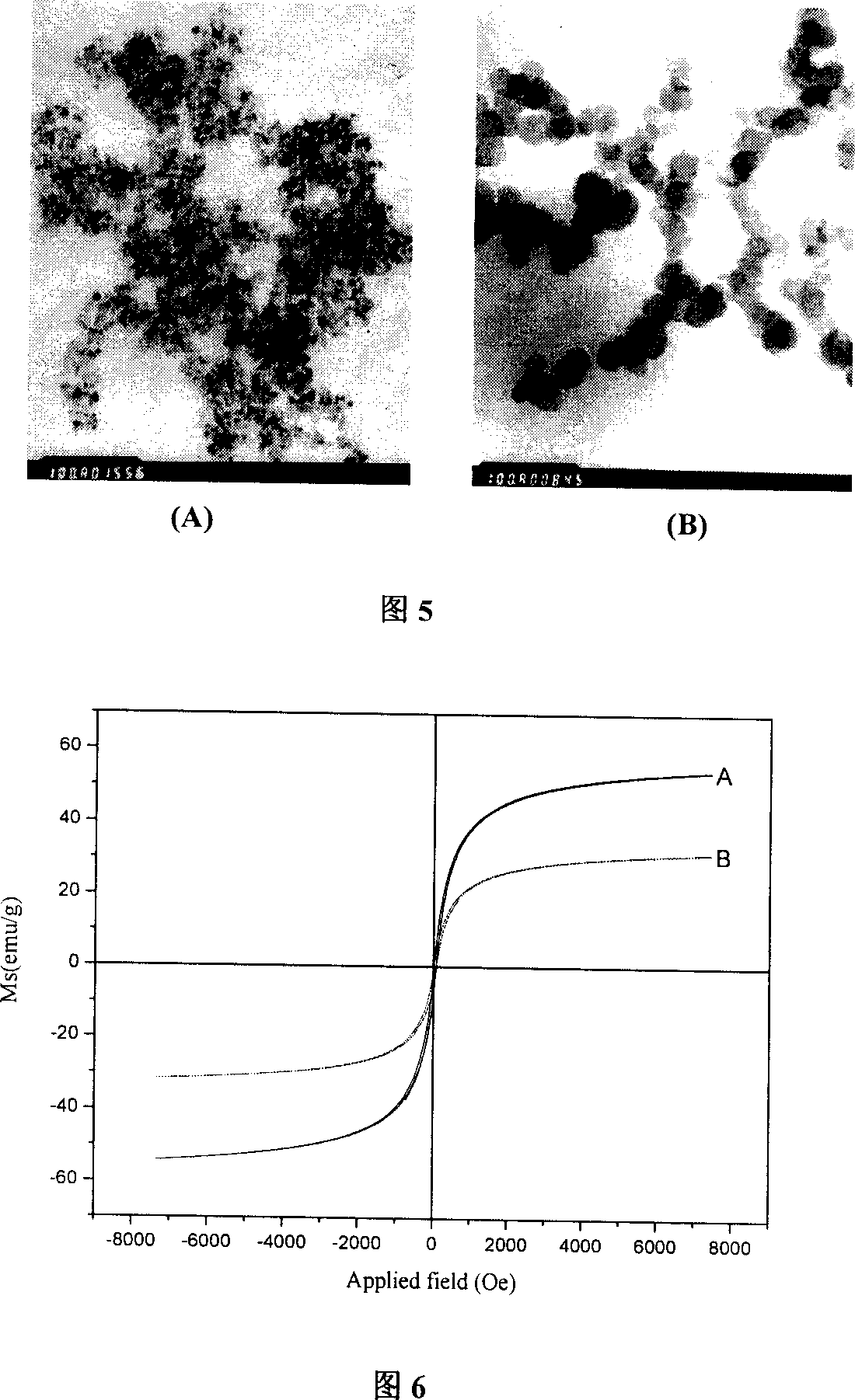

[0022] FeCl 3 and FeSO 4 Mix in a ratio of 1.75:1 and add a small amount of hydrazine hydrate to it. Ultrasonic degassing for 30 minutes, then quickly add 10mL of analytically pure ammonia water under vigorous stirring, after stirring for 15 minutes, slowly add ammonia water dropwise to adjust the pH value to 9, continue to react for 30 minutes, let stand for one day, magnetically separate, wash with deionized water several times, After drying, ferric oxide nanometer powder is obtained.

[0023] A certain concentration of Mn 2+ , Zn 2+ , Fe 3+ Mix the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com