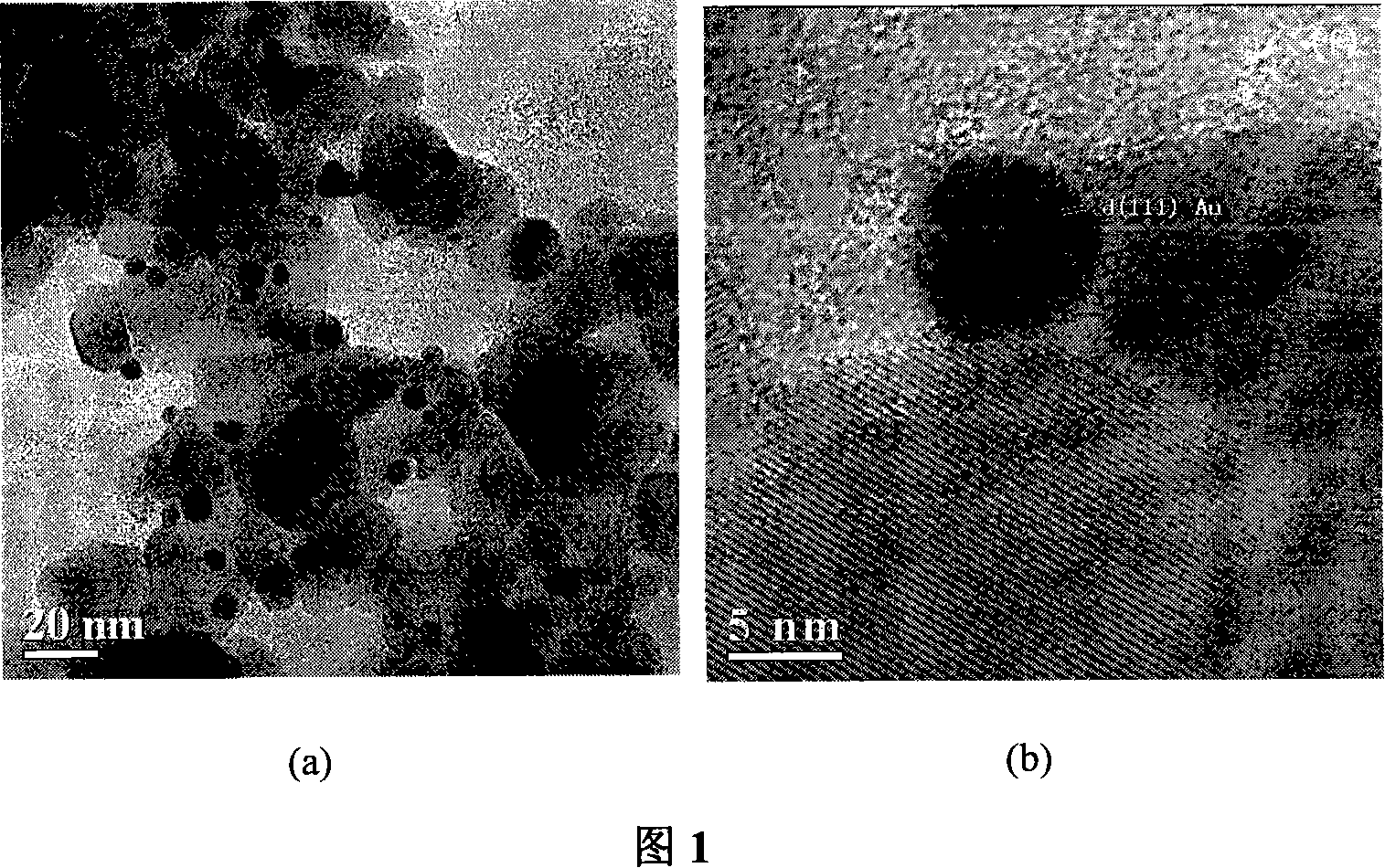

Method for catalytic preparation of gamma-butyrolactone by using supported nano-gold catalyst

A nano-gold and catalyst technology, which is applied in the chemical industry, can solve problems that have not been reported, and achieve the effects of simple process, high catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Add 12.6ml of 0.024mol / L HAuCl to 40ml of deionized water 4 Solution, 3.67g of urea, stirred to dissolve, 2g of P25 was added to the solution, electromagnetically stirred in a water bath at 80°C for 2h, then the stirring was stopped, filtered with suction, washed with deionized water three times, washed with ethanol three times, and dried at room temperature to obtain Au / TiO 2 Catalyst, recorded as 1# catalyst. Reaction conditions: Add 20ml tributyl phosphate as solvent, 1.4g 1,4-butanediol and 0.5g 1# catalyst in the autoclave, seal the autoclave, fill with 1.3Mpa air, 120°C oil bath, electromagnetic stirring reaction 9 hours.

Embodiment 2

[0018] Example 2: Add 12.6ml of 0.024mol / L HAuCl to 40ml of deionized water 4 solution, adding sodium hydroxide solution dropwise to adjust the pH value to 7, adding 2g of P25 to the solution, stirring electromagnetically in a water bath at 20°C for 24h, then stopping the stirring, filtering with suction, washing with deionized water, and drying at 95°C to obtain Catalyst is recorded as 2# catalyst. Reaction conditions: 20ml tributyl phosphate, 1.4g 1,4-butanediol, 0.5g 2# catalyst, 1.3Mpa air, 120°C oil bath, electromagnetic stirring for 9 hours.

Embodiment 3

[0019] Example 3: Add 12.6ml of 0.024mol / L HAuCl to 40ml of deionized water 4 Solution, add sodium hydroxide solution dropwise to adjust the pH value to 14, add 2g P25 to the solution, stir electromagnetically in a water bath at 80°C for 2h, then stop stirring, filter with suction, wash with deionized water, dry at 95°C, and dry at 200°C Lower roasting 4 hours, the catalyst obtained is denoted as 3# catalyst. Reaction conditions: 20ml tributyl phosphate, 1.4g 1,4-butanediol, 0.5g 3# catalyst, 1.3Mpa air, 120°C oil bath, electromagnetic stirring for 9 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com