Capillary electrophoresis-heat working electrode- ampere testing apparatus and heat working electrode preparation method

A production method and amperometric detection technology, applied in the field of chemical analysis, can solve problems such as inability to carry out work, and achieve the effects of easy control of electrode temperature, accurate temperature and strong separation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

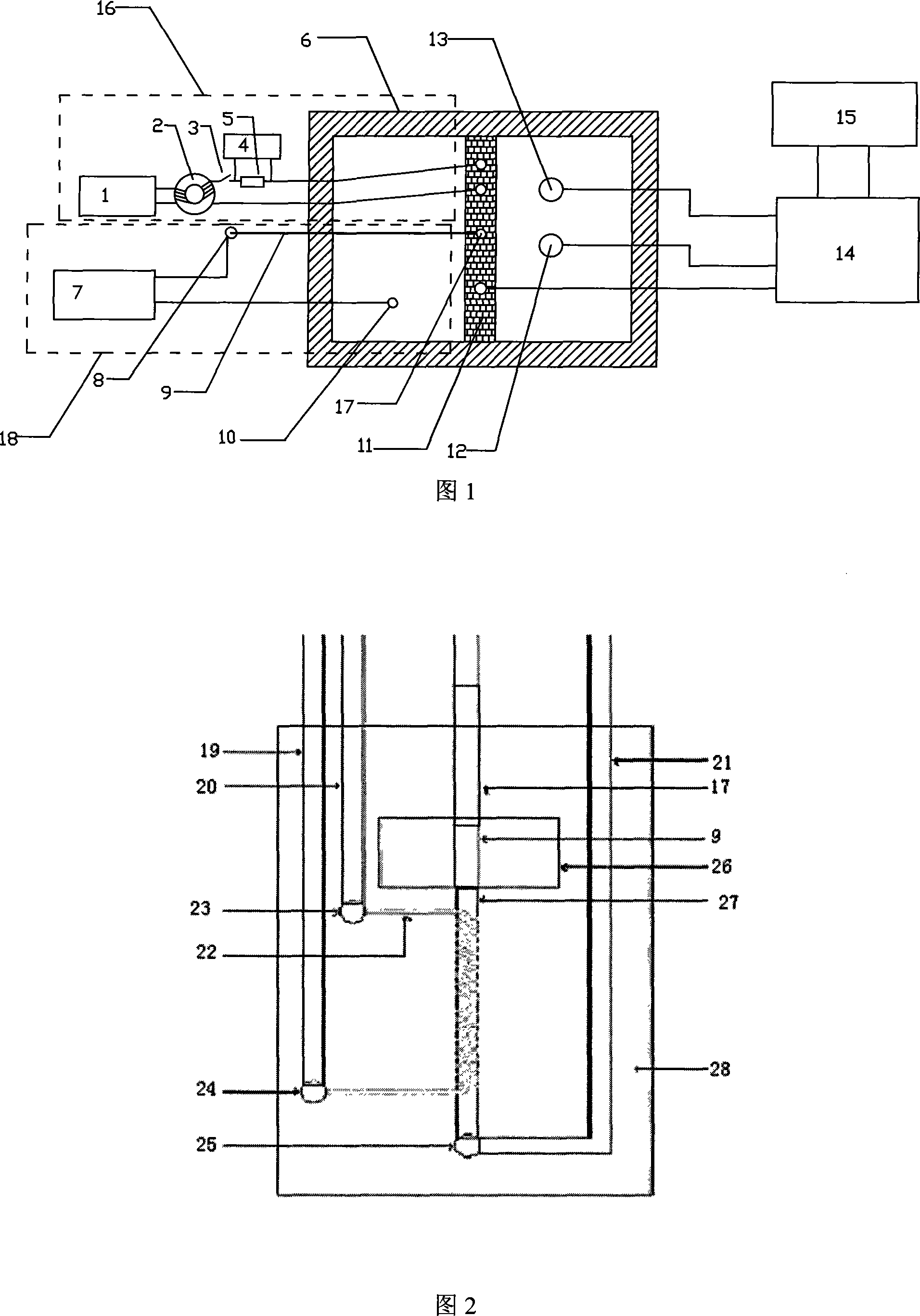

Method used

Image

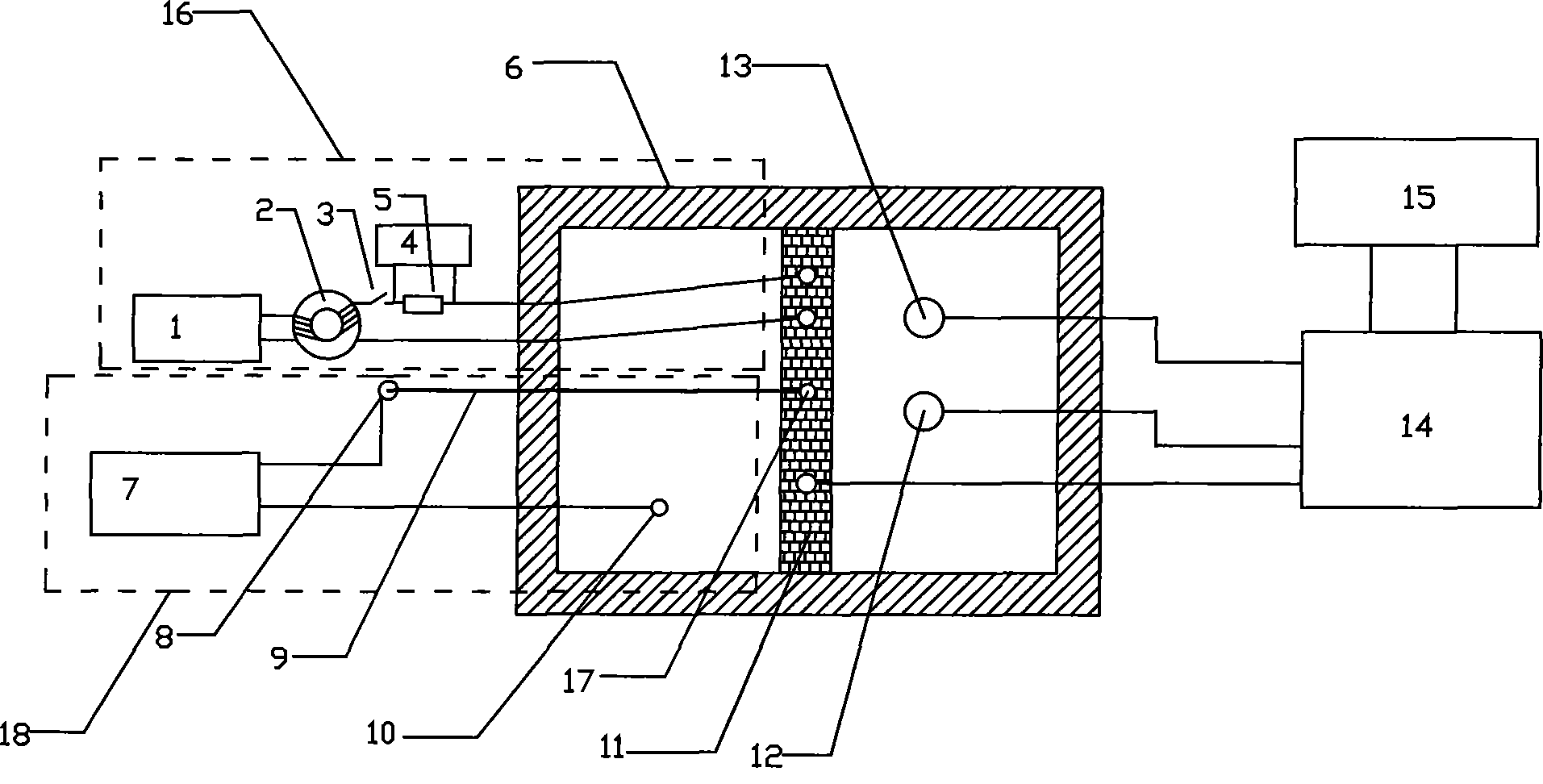

Examples

Embodiment

[0039] 1. Make hot working electrode:

[0040] (1) Evenly wind an enameled wire with a length of 14cm and a diameter of 100μm on a platinum wire with a length of 2cm and a diameter of 0.3mm, burn the two ends of the enameled wire to remove the insulating layer, and soak it in 0.1mol / L sulfuric acid solution for 10min , to remove the oxide layer formed due to fire, and then solder it on two copper enameled wires with a diameter of 0.6mm to lead out as a heating power circuit.

[0041](2) Solder one end of the platinum wire in step 1 to a copper enameled wire with a diameter of 0.6 mm and lead it out as an electrochemical detection end.

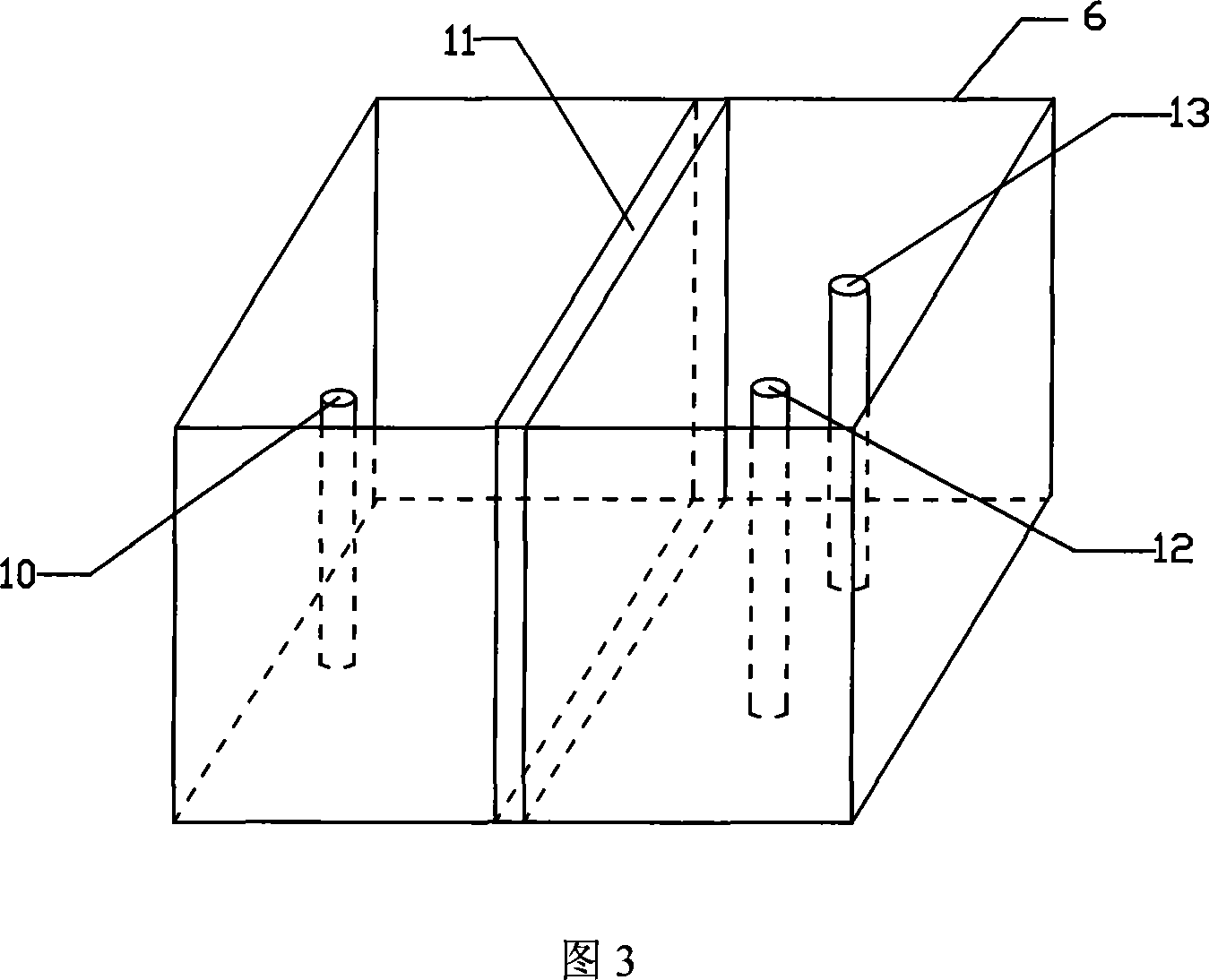

[0042] (3) Fix the whole structure on a 3.5cm×4cm×0.2cm plexiglass (the plexiglass has a window of 0.5cm×1cm in advance, such as figure 2 Middle 26), covered with the same piece of plexiglass, poured a 1:1 mixture of epoxy resin and polyamide resin between the two pieces of plexiglass, and at the same time placed a pair of two ends of the ple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com