Compound fatty milk oral preparation

An oral preparation and fat emulsion technology, applied in the field of compound fat emulsion oral preparations, can solve the problem of not finding the disclosure of compound lipid enteral nutrition technical scheme, achieve significant social and economic benefits, improve disease resistance, and improve intestinal function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

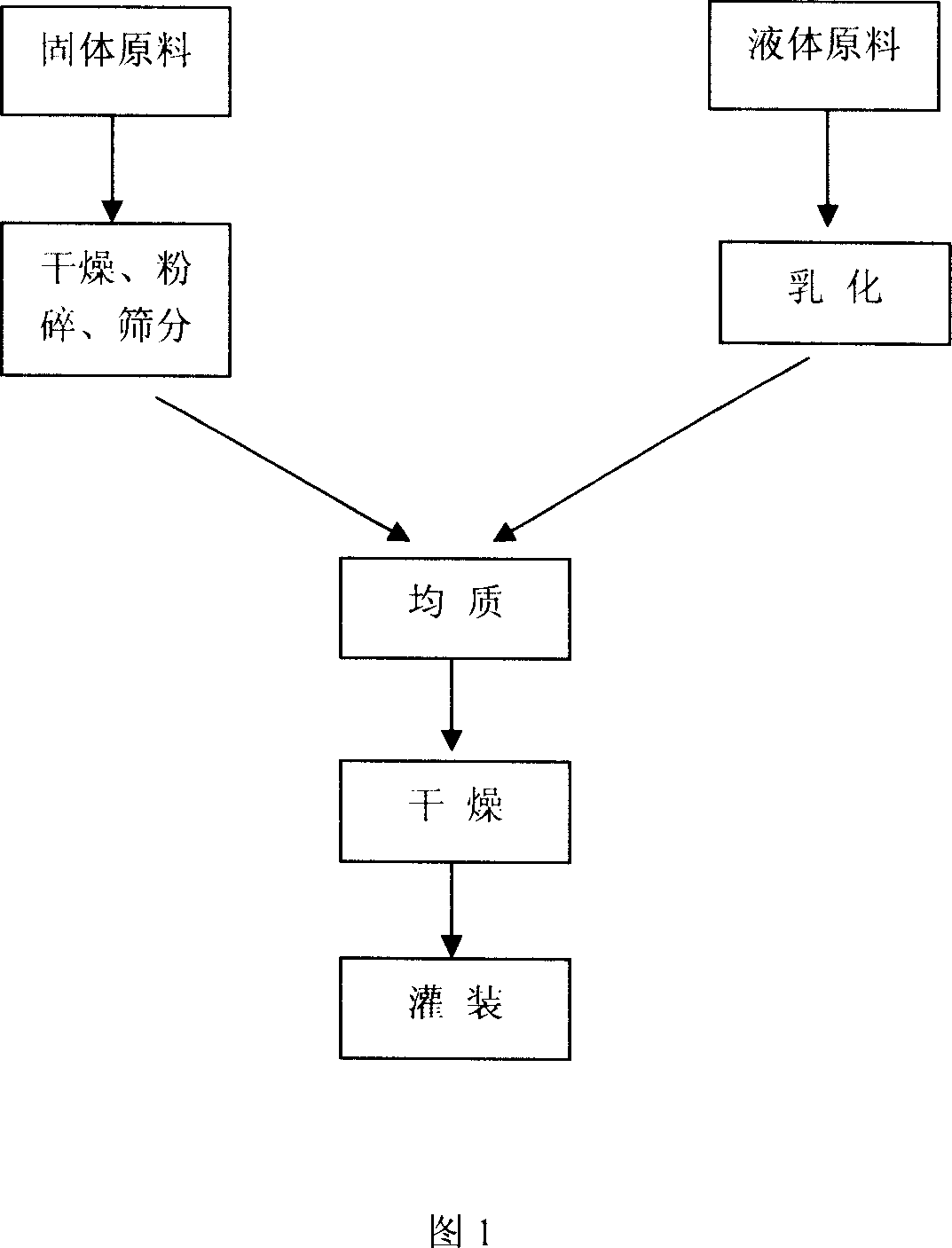

Method used

Image

Examples

Embodiment 1

[0012] Example 1: The raw materials include: medium-chain fatty acid glyceride (MCT), calcium caseinate / sodium caseinate peptide, refined egg yolk lecithin, medicinal glycerin, purified water, and the formula is: 100g of MCT, 10g of refined lecithin, medicinal 22.5g of glycerin, 40g of camelina oil, 20g of calcium caseinate or sodium caseinate peptide, and add purified water to 1000ml.

[0013] The total fat content is 80%, and the fat is mainly medium-chain fatty acid MCT, protein ≥ 14%, and vitamins and minerals 6%.

[0014] The production process is as follows: Refined lecithin is placed in a vacuum homogeneous emulsifier, medicinal glycerin and purified water are added, heated to 40-60°C and stirred at high speed to form a uniform lecithin liquid. Slowly add MCT into the lecithin solution under stirring to form colostrum. Quickly transfer this primary emulsion to a high-pressure homogenizer, turn on the homogenizer and adjust the pressure of the low-pressure valve to 150k...

Embodiment 2

[0017] Example 2: 50g of MCT, 22.5g of medicinal glycerin, 50g of salad oil, 12g of calcium caseinate / sodium caseinate peptide, and purified water to 1000ml.

[0018] Calcium caseinate or sodium caseinate peptide is placed in a vacuum homogeneous emulsifier, medicinal glycerin and purified water are added, heated to 40-60°C and stirred at high speed to form a uniform calcium caseinate or sodium caseinate peptide solution. Slowly add MCT into lecithin calcium caseinate / sodium caseinate peptide solution under stirring to form colostrum. Transfer this primary emulsion to the high-pressure homogenizer quickly, turn on the homogenizer and adjust the pressure of the low-pressure valve to 150kg·cm -2 , high pressure valve pressure to 500 kg·cm -2, adjust the water inlet size of the heat exchanger, and start collecting the homogenized emulsion after the homogenization pressure is stable and the temperature of the homogenized emulsion is stable at 40°C. Homogenization was repeated 10...

Embodiment 3

[0019] Example 3: 70g of MCT, 50g of salad oil, 22.5g of medicinal glycerin, 10g of camelina oil, 12g of calcium caseinate / sodium caseinate peptide, and purified water to 1000ml.

[0020] Calcium caseinate or sodium caseinate peptide is placed in a vacuum homogeneous emulsifier, medicinal glycerin and purified water are added, heated to 40-60°C and stirred at high speed to form a uniform calcium caseinate / sodium caseinate peptide solution. Slowly add MCT into lecithin calcium caseinate / sodium caseinate peptide solution under stirring to form colostrum. Transfer this primary emulsion to the high-pressure homogenizer quickly, turn on the homogenizer and adjust the pressure of the low-pressure valve to 150kg·cm -2 , high pressure valve pressure to 500 kg·cm -2 , adjust the water inlet size of the heat exchanger, and start collecting the homogenized emulsion after the homogenization pressure is stable and the temperature of the homogenized emulsion is stable at 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com