Process for preparing cellulose long-chain fatty acid ester

A long-chain fatty acid ester and long-chain fatty acid technology, which is applied in the application field of ultrasound and microwave, can solve the problems of long-chain acid chlorides such as expensive, difficult to popularize, and large process, and achieve strong reaction performance, interaction performance, and reaction speed Fast, high-yield results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

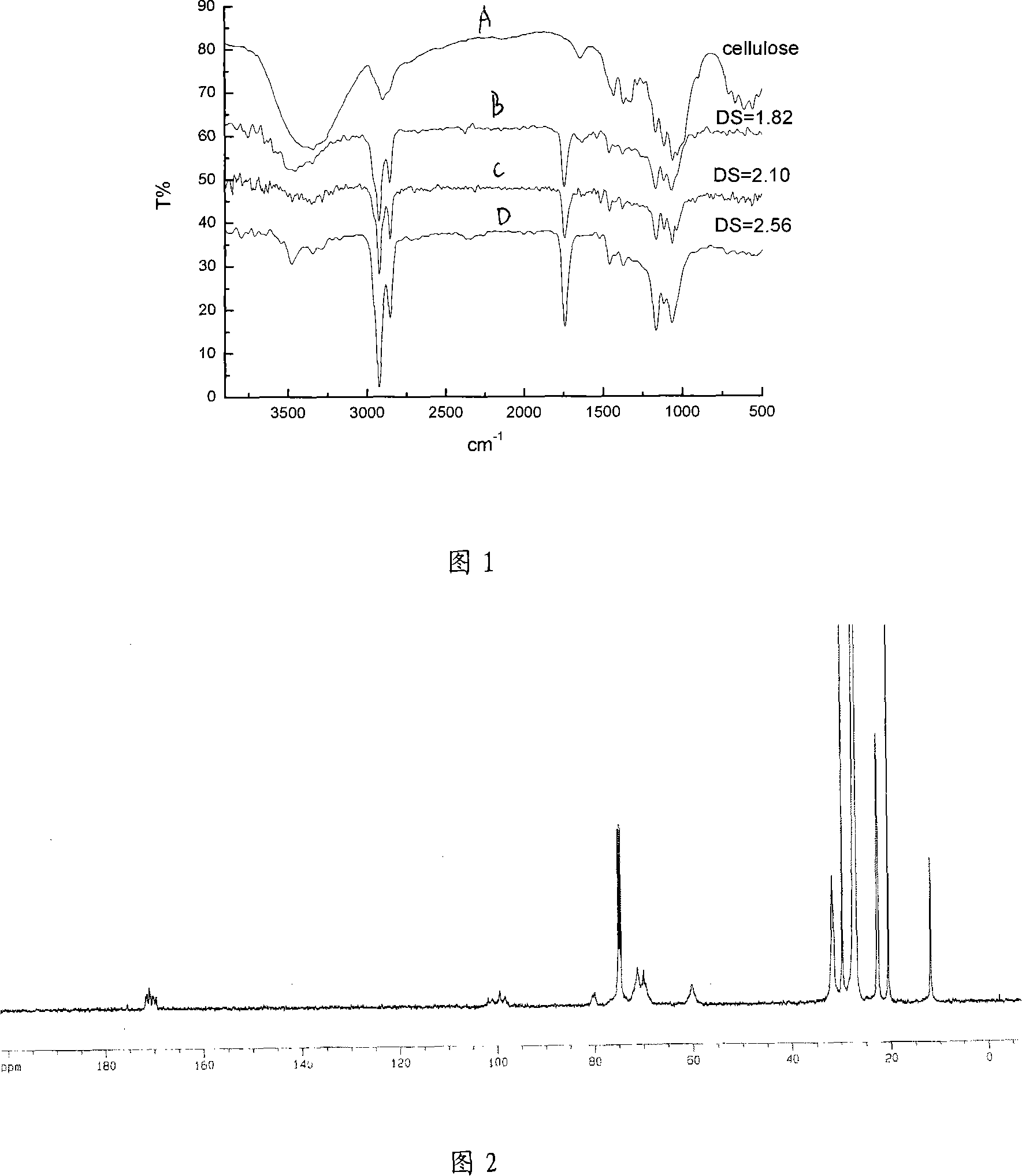

Image

Examples

Embodiment 1

[0024] A preparation method for obtaining the above-mentioned cellulose long-chain fatty acid ester, which utilizes long-chain fatty acids and is synthesized by microwave-assisted technology, and is realized through the following steps:

[0025] a Add 2% to 4% of microcrystalline cellulose and 6% to 9% of lithium chloride into dimethylacetamide, and use 400w to 800w of power and 20 to 25KHz frequency for 5 to 13 Minutes, stirring at room temperature at a speed of 250-500 / min for 2-5 hours to obtain a colorless, transparent cellulose ion solution A;

[0026] b Add cellulose, long-chain fatty acids, and co-reactants in solution A at a molar ratio of 1:2:2 to 1:6:6, and then irradiate in a microwave reactor for 60 seconds to 90 seconds with a power of 300w~400w, the frequency is 2450MHz, stirring under the protection of nitrogen at the same time, the stirring speed is 700-1500 / min, the reaction solution system is stirred by microwave for 1-3 hours, then precipitated and washed wi...

Embodiment 2

[0029] Weigh 2g of microcrystalline cellulose and 8g of lithium chloride into a 150ml beaker filled with 100ml of dimethylacetamide, set the ultrasonic power at 600w and the frequency of 20KHz for 7 minutes, and then transfer it into a 250ml three-port Stir in the flask for 2 hours to obtain a transparent cellulose ion solution, add 9.46g toluene-sulfonyl chloride, 9.93g lauric acid, 1.52g p-methylaminopyridine was irradiated for 90 seconds under the conditions of microwave power 320w and frequency 2450MHz, then stirred for 3 hours, then precipitated with distilled water, filtered and washed, and then washed with NaHCO 3 The solution is washed, and the obtained cellulose laurate is vacuum-dried at 50°C for 12 hours. See the attached table for the results of the product properties.

Embodiment 3

[0031] Weigh 2g of microcrystalline cellulose and 8g of lithium chloride into a 150ml beaker filled with 100ml of dimethylacetamide, set the ultrasonic power at 400w and the frequency of 25KHz for 13 minutes, and then transfer it into a 250ml three-port Stir in the flask for 4.5 hours to obtain a transparent cellulose ion solution. Add 9.46g toluene-sulfonyl chloride, 9.93g lauric acid, and 1.52g p-toluene to this solution in a molar ratio of 1:4:4:1 to cellulose. Aminopyridine was irradiated at a microwave power of 300w for 86 seconds, followed by stirring for another 3 hours, then precipitated with distilled water, filtered and washed, followed by NaHCO 3 The solution is washed, and the obtained cellulose laurate is vacuum-dried at 50°C for 12 hours. See the attached table for the results of the product properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com