Oil field re-injection water microbiological treatment

A technology for microbial treatment and oilfield reinjection water, applied in the direction of sustainable biological treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc. Issues such as oil removal effect are disclosed to achieve stable treatment effect, reduced backwashing frequency, and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

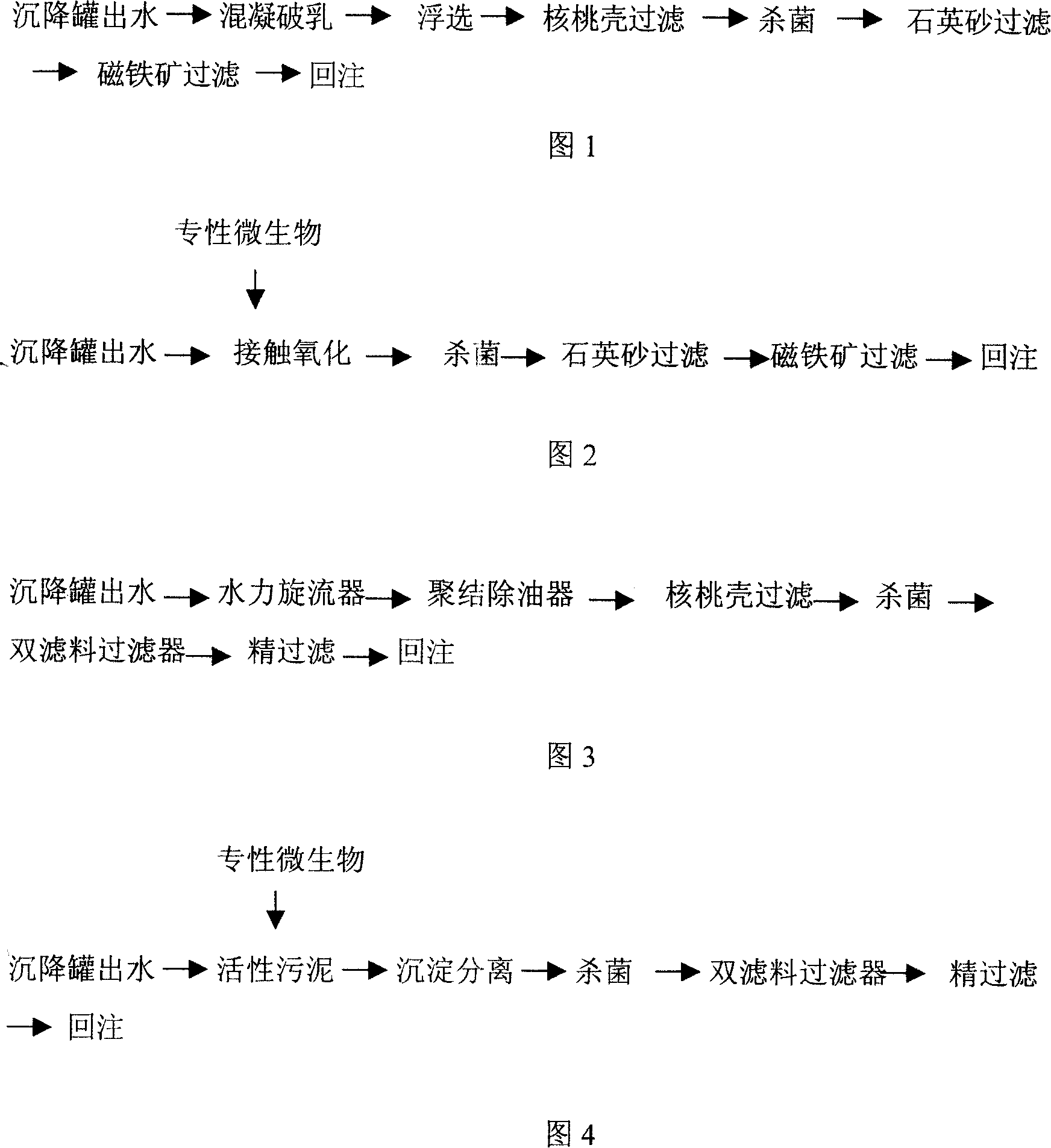

[0028] Embodiment 1: according to Fig. 2 processing flow, processing result is shown in Table 2

[0029] Table 2 Example 1 treated effluent unit mg / L

[0030] project

[0031] Explanation: The water inflow of Comparative Example 1 and Example 1 is the same water from a settling tank in an oil field, pH8.2, T38℃, water volume: 5m 3 / H, degree of salinity: 25000mg / L, polymer: 275mg / L, the process of Comparative Example 1 was adopted before the transformation, and the process of Example 1 of the present invention was adopted after the transformation, and the original sterilization, quartz sand filter and magnetite filter were retained Only the original coagulation and demulsification, flotation, walnut shell filtration, and use Bacillus cereus, Corynebacterium sp., Bacillus subtilis, alkagenes Bacteria (Pseudomonas alcaligenes), Pseudomonas stutzeri (Pseudomonas stutzeri), Bacillus licheniformis (Bacillus licheniformis) joint bacteria contact oxidation (semi-soft fill...

Embodiment 2

[0035] Embodiment 2: according to Fig. 4 processing flow, processing sees Table 4.

[0036] Table 4 Example 2 treated effluent unit mg / L

[0037] project

Water out of the settling tank

Precipitation separated out

water

Fine filtered water

average removal rate

Oil

226

2.2

0.3

99.9%

SS

165

30

1.8

98.9%

median particle size

≤0.82μm

Saprophytes

≥10 6 pcs / ml

≤10 / mL

99.99%

SBR

≥10 6 pcs / ml

not detected

100

TGB

≥10 6 pcs / ml

≤10 / mL

99.99%

Dual Material Filter Cleaning Cycle

Wash every 10 days

Fine filter cleaning cycle

After more than half a year of operation, it still maintains good effluent quality

[0038] Explanation: The water inflow of Comparative Example 2 and Example 2 is the water outflow from the same oilfield settling tank, pH7.2, T35℃, water volume: 5m 3 / H, salin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com