Hydroprocessing technique

A technology of hydrogenation treatment and process method, which is applied in the direction of refining to remove heteroatoms, etc., which can solve the problems of low catalyst production efficiency, inability to completely solve the problem of self-heating of sulfided catalysts, unfavorable hydrogenation treatment process, etc., and shorten the sulfidation time , suitable for large-scale use, and the effect of improving the vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

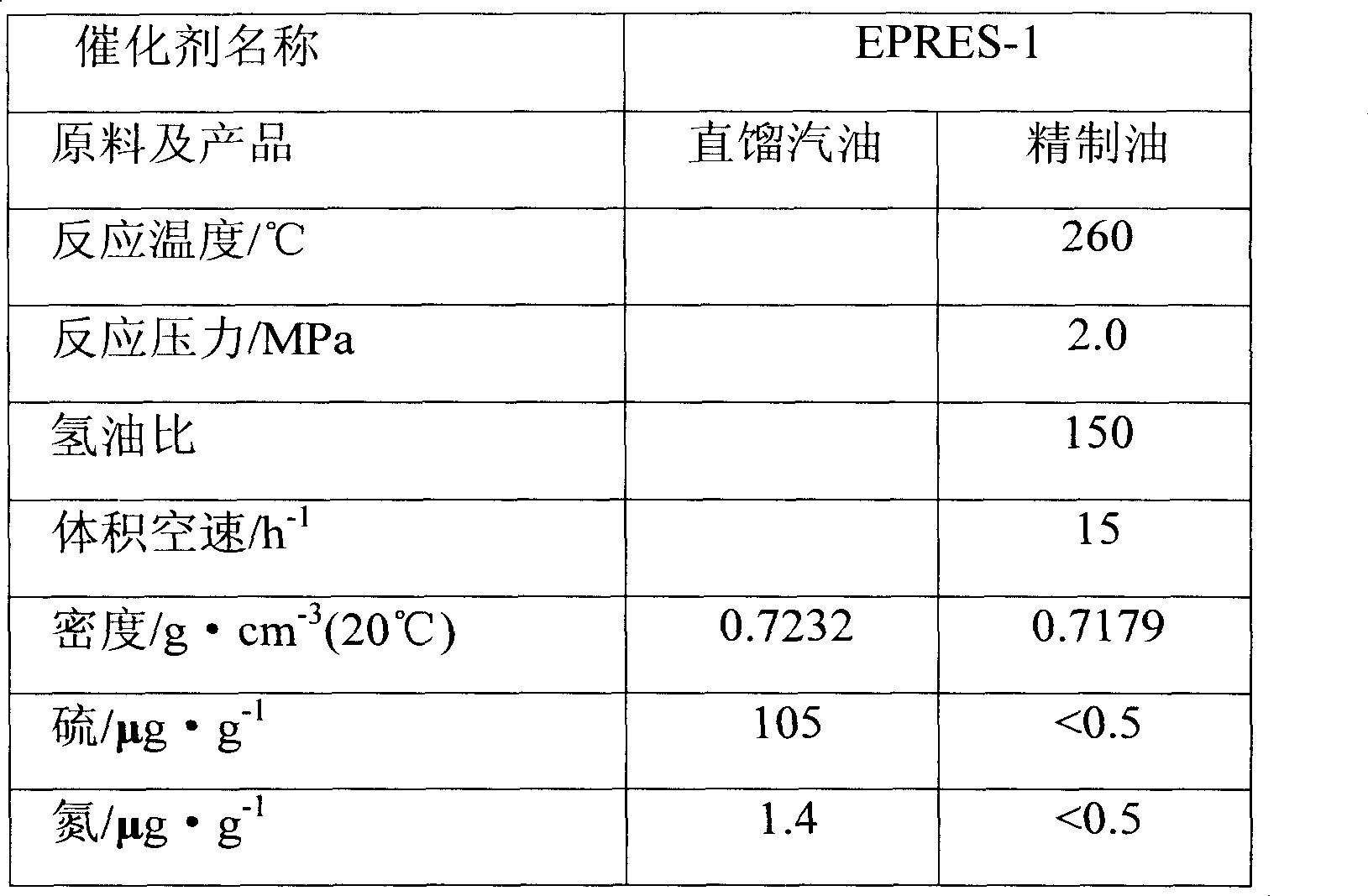

[0030] The commercial hydrodesulfurization catalyst FH-5A (developed by Fushun Petrochemical Research Institute and produced by Wenzhou Huahua Group Co., Ltd.) was selected. The main composition and properties are shown in Table 1.

[0031] The specific pre-sulfurization process is as follows:

[0032] (1) Add 23 grams of thiourea dioxide into 100 ml of clean water, heat to 60° C., and stir for 15 minutes while heating. The obtained thiourea dioxide solution was stirred for 30 minutes, and purified water was added to 150 milliliters. Get 200 grams of oxidized FH-5A catalyst and add it into a prepared rotatable or vibrating container, spray the above solution, the total amount of the solution is 100 milliliters. Then turn or shake for 20 minutes. The impregnated material was dried in air at 120°C for 5 hours. Thiourea dioxide accounted for 7.7% by weight of the catalyst.

[0033] (2) introducing molten elemental sulfur into the catalyst containing the obtained step (1), whe...

Embodiment 2

[0036] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

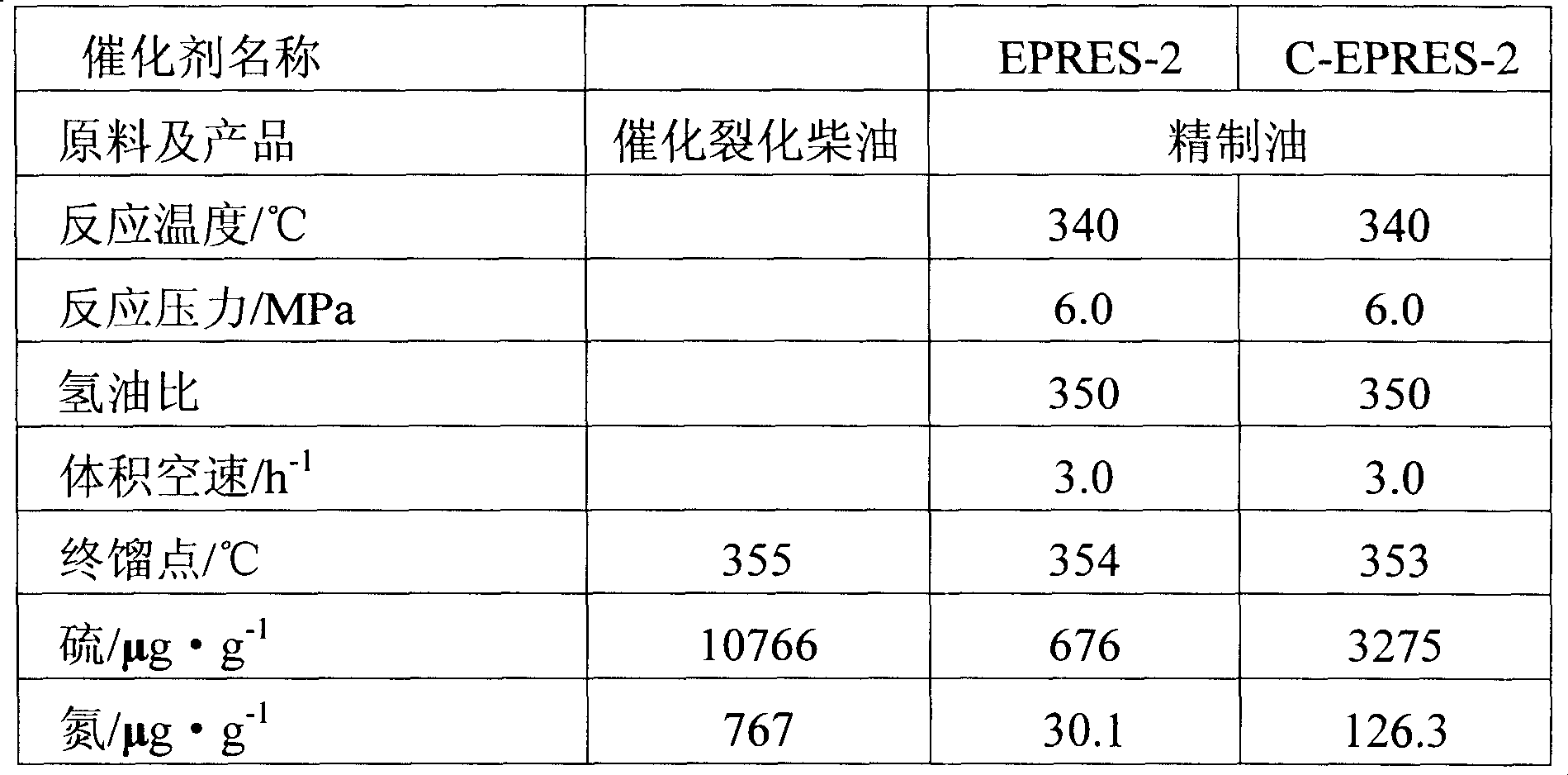

[0037] Vulcanization treatment method is the same as embodiment 1, just adds 3 grams of citric acid to the thiourea dioxide solution of gained in step 1. A hydrorefining catalyst EPRES-2 containing a sulfurizing agent was obtained.

Embodiment 3

[0041] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

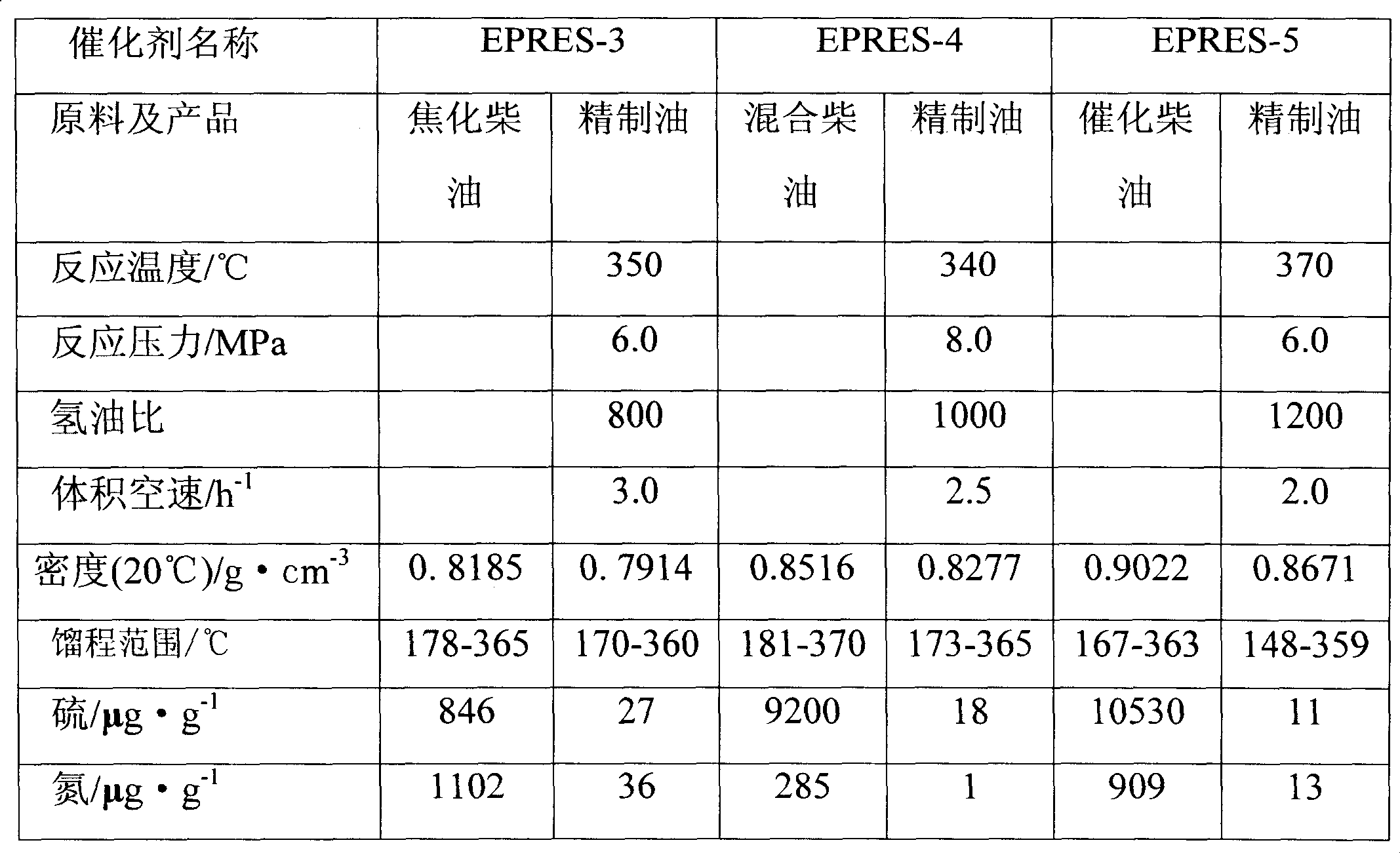

[0042] The vulcanization treatment method is the same as embodiment 2, except that the thiourea dioxide solution obtained in the step 1 is changed into a thiourea solution, and the thiourea consumption accounts for 10% of the catalyst weight, and the others remain unchanged. A hydrorefining catalyst catalyst EPRES-3 containing a sulfurizing agent was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com