Method for preparing ball-shaped bump biological microelectrode array

A technology of micro-electrode arrays and spherical protrusions, which is applied in the direction of optomechanical equipment, chemical instruments and methods, circuits, etc., can solve the problems of increasing the impedance of electrodes and tissues, which is not conducive to the transmission of stimulation signals, and the contact resistance between metals becomes larger. To achieve the effect of improving stimulation effect, improving stimulation effect and reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

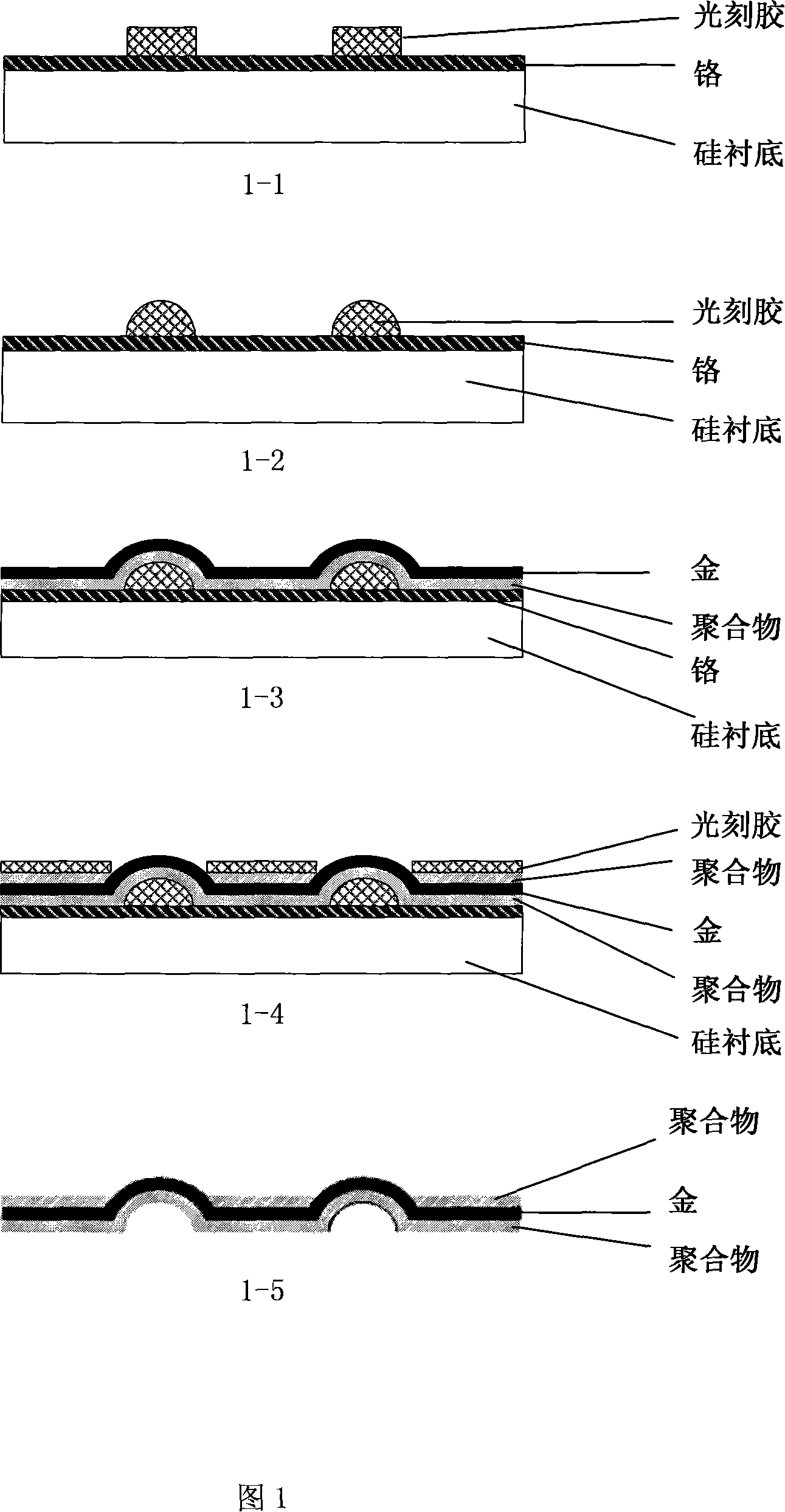

[0030] 1. Clean the silicon wafer, and sputter metal chromium (Cr) on the silicon wafer to 800 Ȧ;

[0031] 2. Spin-coat positive photoresist AZ4903 (1200 rpm, 60 seconds) on the metal surface, expose, remove the photoresist in the exposed area with AZ-400K developer (160 seconds to 200 seconds), and obtain a raised photoresist The small cylinder is 15um, as shown in Figure 1-1;

[0032] 3. Bake the photoresist in an oven at a high temperature at 160C-200C for 20-30 minutes to form a photoresist with a hemispherical structure, as shown in Figure 1-2;

[0033] 4. Deposit the polymer parylene7-8um, as the bottom wrapping material of the microelectrode array;

[0034] 5. Sputter metal gold 0.5um, spin-coat photoresist AZ4903 (3000 rpm, 60 seconds), expose, develop (140 seconds to 160 seconds), pattern the wires and electrode points of the microelectrode array, as shown in Figure 1 -3;

[0035] 6. Deposit the polymer parylene5um as the upper wrapping material of the microelectro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com