Device for eliminating aflatoxin

A kind of technology of aflatoxin and cracking device, which is applied in the field of edible liquid processing equipment, can solve the problems of low removal rate, poor operability, change of food color and taste, etc., and achieve a high degree of mechanization, ensure product quality, and high processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

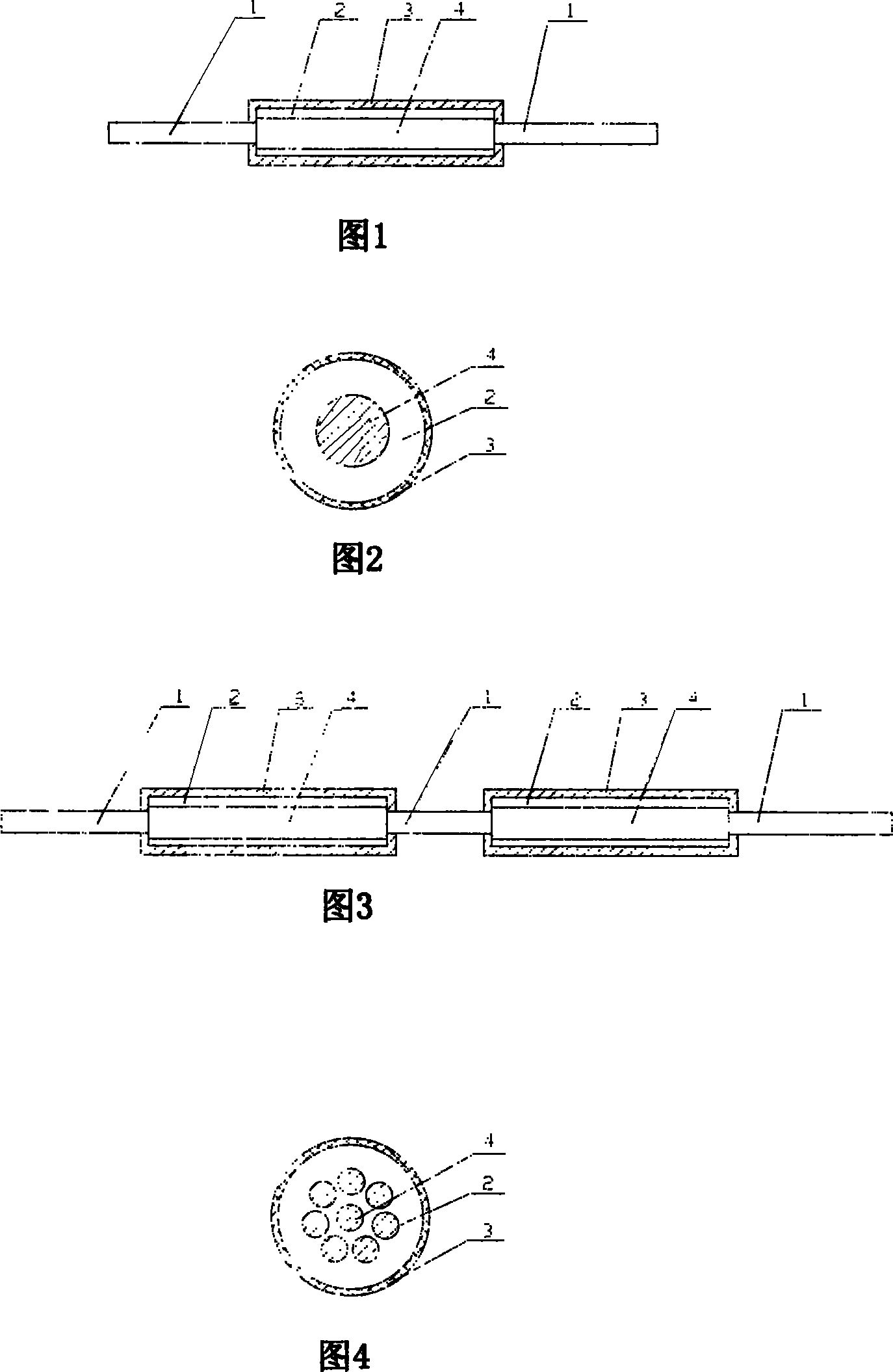

[0020] Embodiment 1, a kind of device that removes aflatoxin, with reference to Fig. 1, Fig. 2, be to be provided with ultraviolet cracking device 2 on liquid delivery pipeline 1, this device 2 is to be provided with ultraviolet generator at the center of housing 3 4. The ultraviolet generator 4 is controlled by an external controller, and a gap is formed between the casing 3 and the ultraviolet generator 4, which constitutes a structure of the present invention.

Embodiment 2

[0021] Embodiment 2, a kind of device that removes aflatoxin, with reference to Fig. 3, Fig. 4, is on the basis of embodiment 1, is connected with a plurality of ultraviolet cracking devices 2 in series in pipeline 1, and ultraviolet cracking device 2 generally adopts 1 -20, the present embodiment adopts 2 cracking devices connected in series on the pipeline 1, and the ultraviolet generator 4 is formed by a plurality of ultraviolet generators 4 connected in parallel, and the present embodiment adopts 8 ultraviolet generators 4 connected in parallel, and the housing The inner wall of 3 is a reflection layer, and the others are identical to embodiment 1.

Embodiment 3

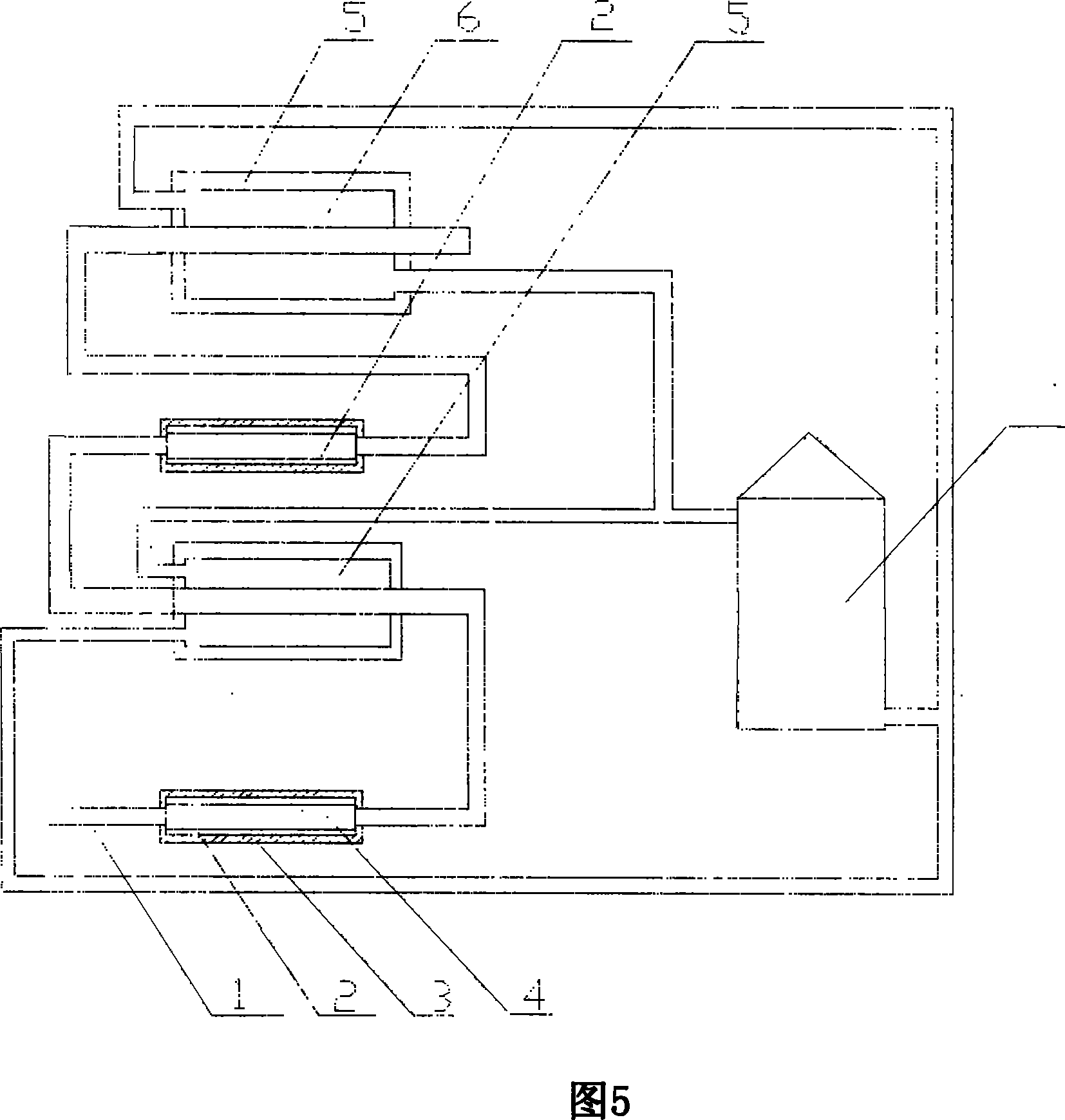

[0022] Embodiment 3, a kind of device that removes aflatoxin, with reference to Fig. 3, Fig. 4, Fig. 5, is on the basis of embodiment 2, is provided with cooling device 5 on the pipeline 1 after each cracking device 2, The cooling device 5 is provided with a heat exchanging device 6 outside the pipeline 1, and the water inlet and the water outlet of the heat exchanging device 6 are respectively connected with the water outlet and the water inlet of the cooling tower 7, and the others are identical to the embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com