Composite preparation made from microorganism fermented liquid

A technology for microbial fermentation liquid and preparation, applied in the field of microbiology, can solve the problems of no preventive activity against plant diseases, no control of bacterial infection, plant damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] 1) Add 20 grams of glucose and malt extract powder, 5 grams of yeast extract powder, 5 grams of calcium trehalose ammonia, 15 grams of agar, and add water to 1 liter. After being sterilized and cooled, pour it into a petri dish to make a culture medium (GMYAA). Streak culture on the culture medium with Pseudomonas glathei TP06, a related strain selected from the genus Pseudomonas, was cultured for 48 hours to obtain strains.

[0019] 2) Transfer the strain from the culture medium to the GMYAB-containing culture medium (20 grams of glucose and malt extract powder each, add 5 grams of yeast extract powder, 5 grams of calcium trehalose ammonia, add water to 1 liter), at a temperature of 30 ° C and a rotation speed of 125 rpm Incubate on a shaker for 72 hours under optimal conditions.

[0020] 3) Transfer the cultured strains to a fermenter with a 10% inoculum amount, and use the same culture solution as that in the seed tank for aerated fermentation at 30° C. for 72 hours...

example 2

[0022] Example 2. The content of fatty acid in the multi-effect preparation was determined by gas chromatography-mass spectrometry according to the following conditions.

[0023] 1. Instrument Agilent Technologies GC / MS 5975i

[0024] 2. Chromatographic column: HP-5ms (30m×250μm×0.25μm) 5%PhenyMethylSiloxane

[0025] 3. Chromatographic column temperature program: keep at 100°C for 1min, then program temperature up to 130°C at 30°C / min, then program temperature up to 250°C at 5°C / min, then program temperature up to 300°C at 10°C / min, keep for 5min ;

[0026] 4. Carrier gas: helium, purity ≥ 99.999%, flow rate 1.2mL / min;

[0027] 5. Inlet temperature: 290°C;

[0028] 6. Injection volume: 2μL;

[0029] 7. Sampling method: non-split sampling;

[0030] 8. Electron bombardment source: 70eV;

[0031] 9. Quadrupole temperature: 150°C;

[0032] 10. Ion source temperature: 230°C;

[0033] 11. GC-MS interface temperature: 280°C;

[0034] Full spectrum scan; mass scan range m / z: ...

example 3

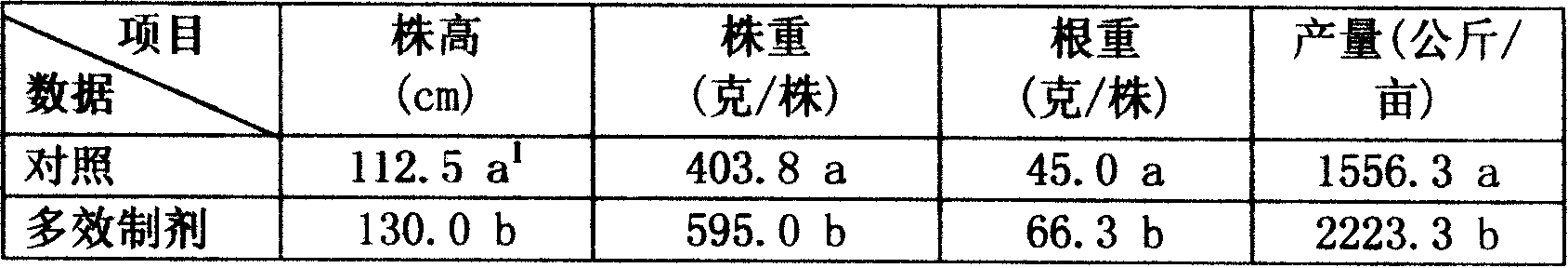

[0038] Example 3. The effect of multi-effect preparation on promoting plant growth and increasing yield

[0039] Take 100 ml of the multi-effect preparation, dilute it with water 100 times, and evenly spray it on the newly transplanted eggplant leaves in the field, spray once every 15 days, do not use any chemical fungicides and topdressing, and spray chemical pesticides and topdressing on adjacent plots conventional management as a comparison. The results are shown in Table 2. The multi-effect preparation significantly promotes the growth of crops, and obtains a yield increasing effect of up to 42%.

[0040] Table 2 Comparison of effects of multi-effect preparations on promoting growth and increasing yield of eggplant

[0041]

[0042] Note 1: Different letters after the numbers in the same column indicate significant differences between treatment and control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com