Pouring material for producing high-temperature ceramic abrasion-proof lining body

A technology for high-temperature ceramics and castables, applied in the field of castables, can solve problems such as scratches and chemical corrosion on the surface of the brick body, aggravate the erosion and peeling of the lining body, and high production costs, and achieve excellent high-temperature mechanical properties. Effect of finish and integrity, good high temperature chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

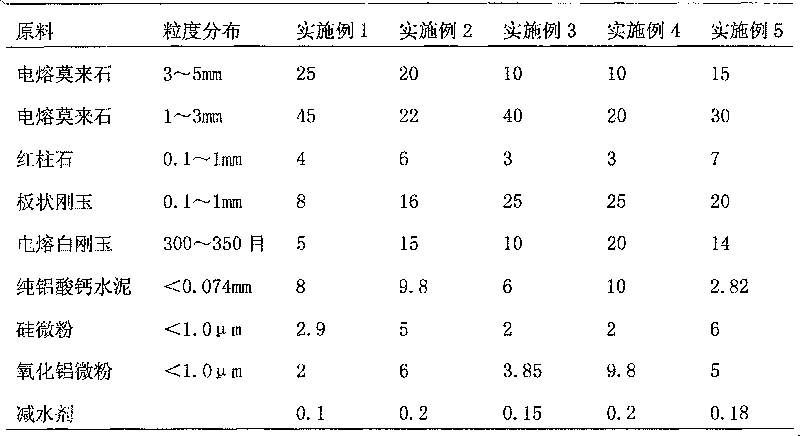

[0064] Example 1 A castable for preparing a high-temperature ceramic wear-resistant lining, its raw material formula is shown in Table 1:

[0065] Weigh various materials according to the proportions stated in Table 1, put them into a forced mixer and mix for 3 to 5 minutes, then add water (the amount of water added is 4 to 6% of the total weight of the materials), mix and stir evenly, and then inject and fix Vibration forming in the mold. When pouring thick material layer, vibrating rod should be used for layered pouring, and it can be finished after the surface is flooded. Curing for 3 days after casting and baking at 110°C to obtain a high-temperature super wear-resistant ceramic lining, which can be used as a lining at the intersection of the blast furnace hot air pipe and the air supply pipe, and can also be used in other similar environments As a lining. The main technical indicators achieved by the lining are as follows:

[0066] Al 2 o 3 (%) ≥70

[0067] Refractor...

Embodiment 2

[0072] Example 2 A castable for preparing a high-temperature ceramic wear-resistant lining, its raw material formula is shown in Table 1:

[0073] The method of making lining body with this castable is the same as embodiment 1, and the main technical index that this lining body reaches is as follows:

[0074] Al 2 o 3 (%) ≥70

[0075] Refractory temperature (℃) >1790

[0076] Compressive strength (MPa) 63(110℃×24h); 160(1450℃×3h)

[0077] Flexural strength (Mpa) 12(110℃×24h); 14(1450℃×3h)

[0078] Line change after burning (%) ±0.1(110℃×24h); ±0.1(1450℃×3h)

[0079] Thermal shock stability (times) 38 (1100°C water cooling)

Embodiment 3

[0080] Example 3 A castable for preparing a high-temperature ceramic wear-resistant lining, whose raw material formula is shown in Table 1:

[0081] The method of making lining body with this castable is the same as embodiment 1, and the main technical index that this lining body reaches is as follows:

[0082] Al 2 o 3 (%) ≥70

[0083] Refractory temperature (℃) >1790

[0084] Compressive strength (MPa) 62(110℃×24h); 149(1450℃×3h)

[0085] Flexural strength (Mpa) 12(110℃×24h); 16(1450℃×3h)

[0086] Line change after burning (%) ±0.1(110℃×24h); ±0.1(1450℃×3h)

[0087] Thermal shock stability (times) 34 (1100°C water cooling)

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com