Non-magnetic single-component toner, method of prepairing the same, and image forming apparatus using the same

A toner, negatively charged technology, applied in the field of single-component non-magnetic toner, can solve the problems of reduced transfer efficiency, reduced toner charge, and increased removal of toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

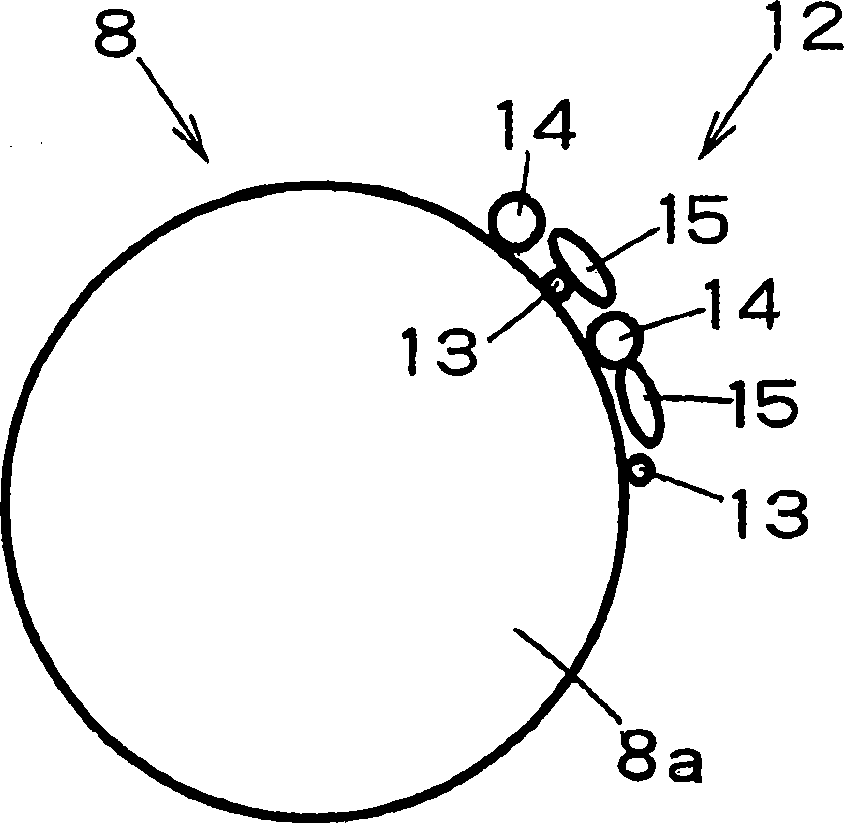

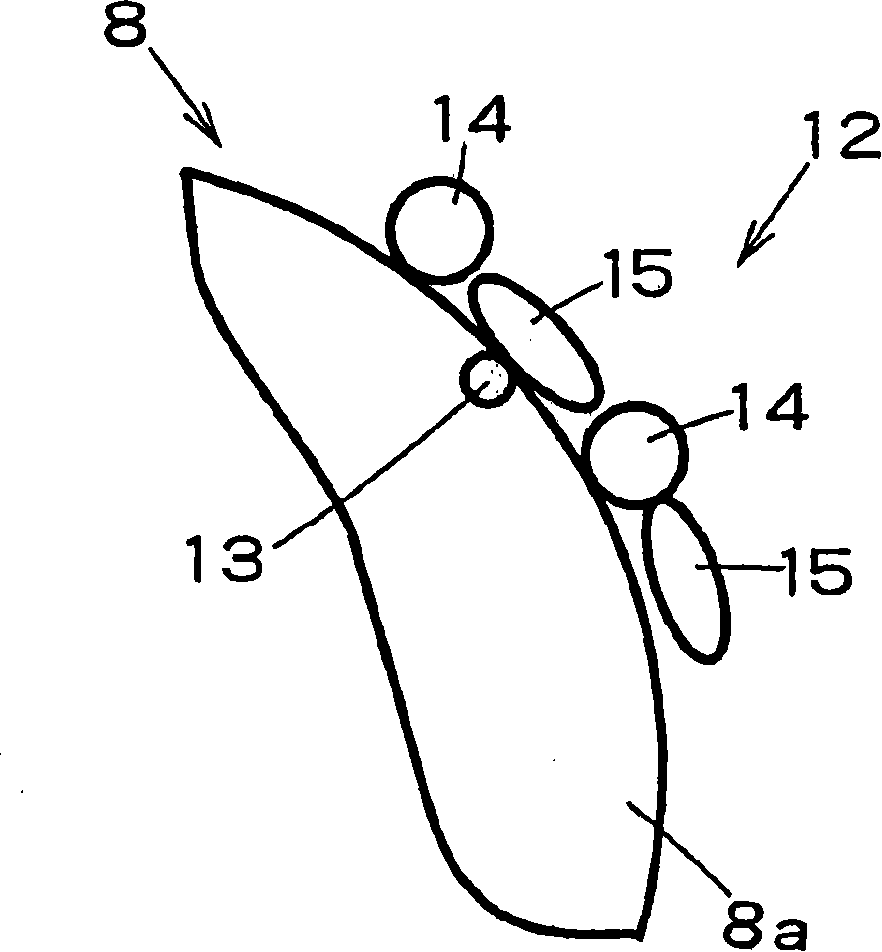

[0190] Examples and comparative examples of the present invention, in which one-component non-magnetic toners were produced, were subjected to image forming tests. These examples and each comparative example and the imaging test used in the following description Figure 5 An example of the manufacture of an organic photoreceptor for an image forming apparatus performed by a non-contact one-component development process, and a transfer medium is shown.

[0191] Manufacture of one-component non-magnetic toner 8

[0192] In Examples and Comparative Examples of One-Component Non-magnetic Toner 8, two types of toners, the above-mentioned polymerization method toner and pulverization method toner, were produced. At this time, the flow improver (additive) used in the production of the toner of each example is hydrophobic rutile anatase-type titanium oxide (20 nm) with a major axis length of 20 nm, and a small particle size with an average primary particle size of 12 nm. Hydrophobic...

manufacture example 2

[0343] In the production of the organic multilayer photoreceptor 1 of Production Example 2, a seamless nickel electroforming tube with a thickness of 40 μm and a diameter of 85.5 mm was used on the conductive support frame 1 a, and the following structural formula ( 2) except for the distyryl compound, Organic Photoreceptor 1 (OPC2) was produced in the same manner as Production Example 1. The work function of this organic multilayer photoreceptor was similarly measured and found to be 5.50 eV.

[0344]

[0345] Structural formula (2)

[0346] Fabrication example of developing roller 11

[0347] The developing roller 11 is a surface having a surface roughness (Ra) of 4 μm by performing nickel plating (23 μm in thickness) on the surface of an aluminum tube with a diameter of 18 mm. A part of the surface of the developing roller 11 was cut off, and the work function was similarly measured, and found to be 4.58 eV.

[0348] Making of Toner Regulating Knife

[0349] The toner ...

Embodiment 6

[0375] Using the toner of Example 8 and Comparative Examples 7 to 9, after image formation in the contact development mode of image formation test 5, a fixability comparison was performed using a fixing device 60 described below.

[0376] The fuser 60 uses a φ40 heating roller (with a built-in 600W halogen lamp, forming a 50 μm thick PFA film on a silicone rubber 2.5mm (60°JISA)) and a φ40 pressure roller (with a built-in 300W halogen lamp, on a silicone rubber 2.5mm ( 60°JISA) was fixed with two pressure rollers (load of about 38kgf) with PFA formed into a film of 50μm thick) at a set temperature of 190°, and the fixability of each toner was compared. A weight of 200 g is placed on the cotton cloth, rubbed 50 times on the entire image, and the density of the entire image before and after rubbing is measured, and the fixability of the toner is converted into a retention rate (fixation rate) (%), which is used as an index of the fixability evaluation index. The results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average primary particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com