Method of making alkoxylates

A compound and a technology for producing alkanes, applied in sustainable manufacturing/processing, ether preparation, organic chemistry, etc., can solve problems such as volatility instability, concentration, and non-optimal product properties of ethylene oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

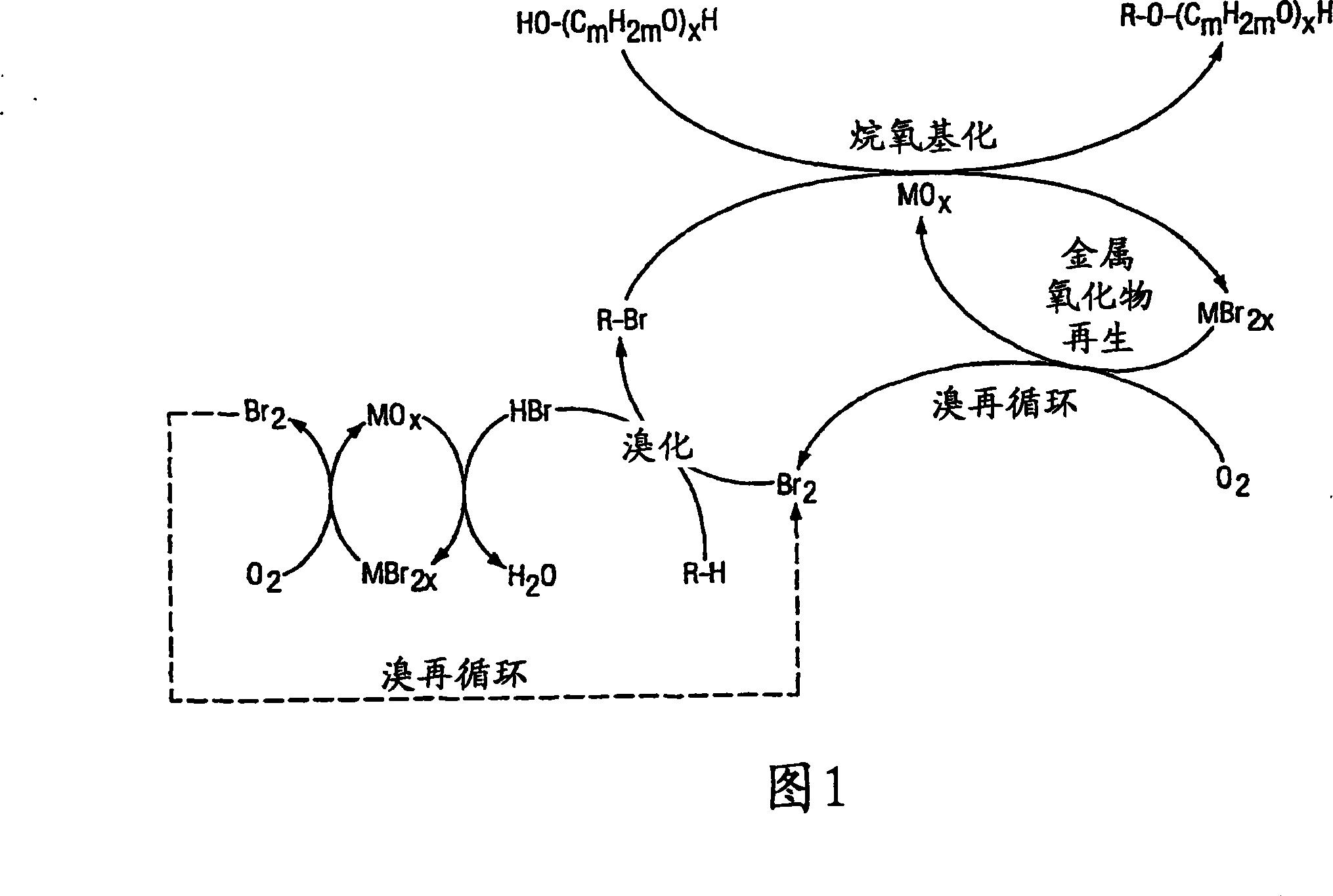

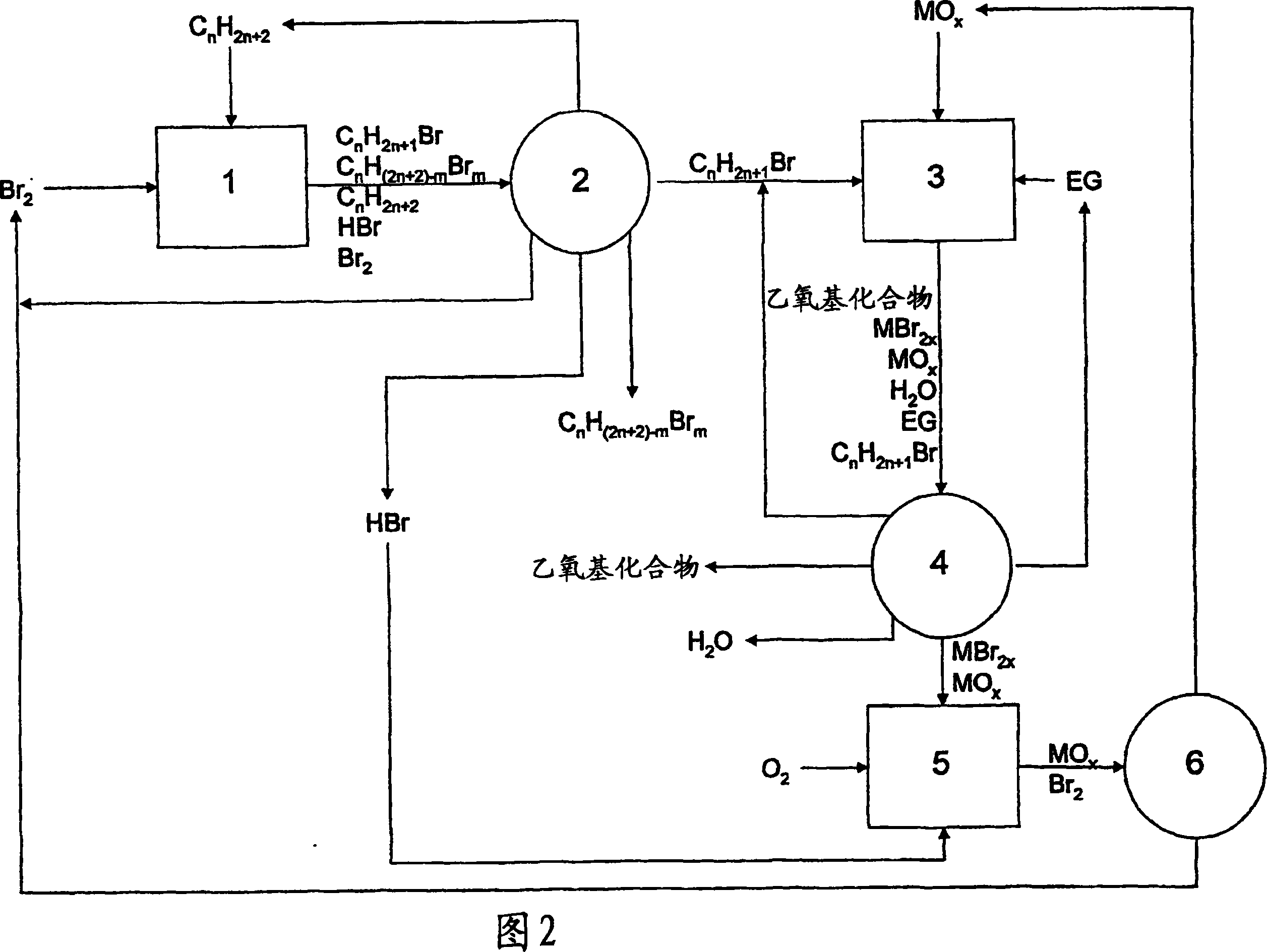

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

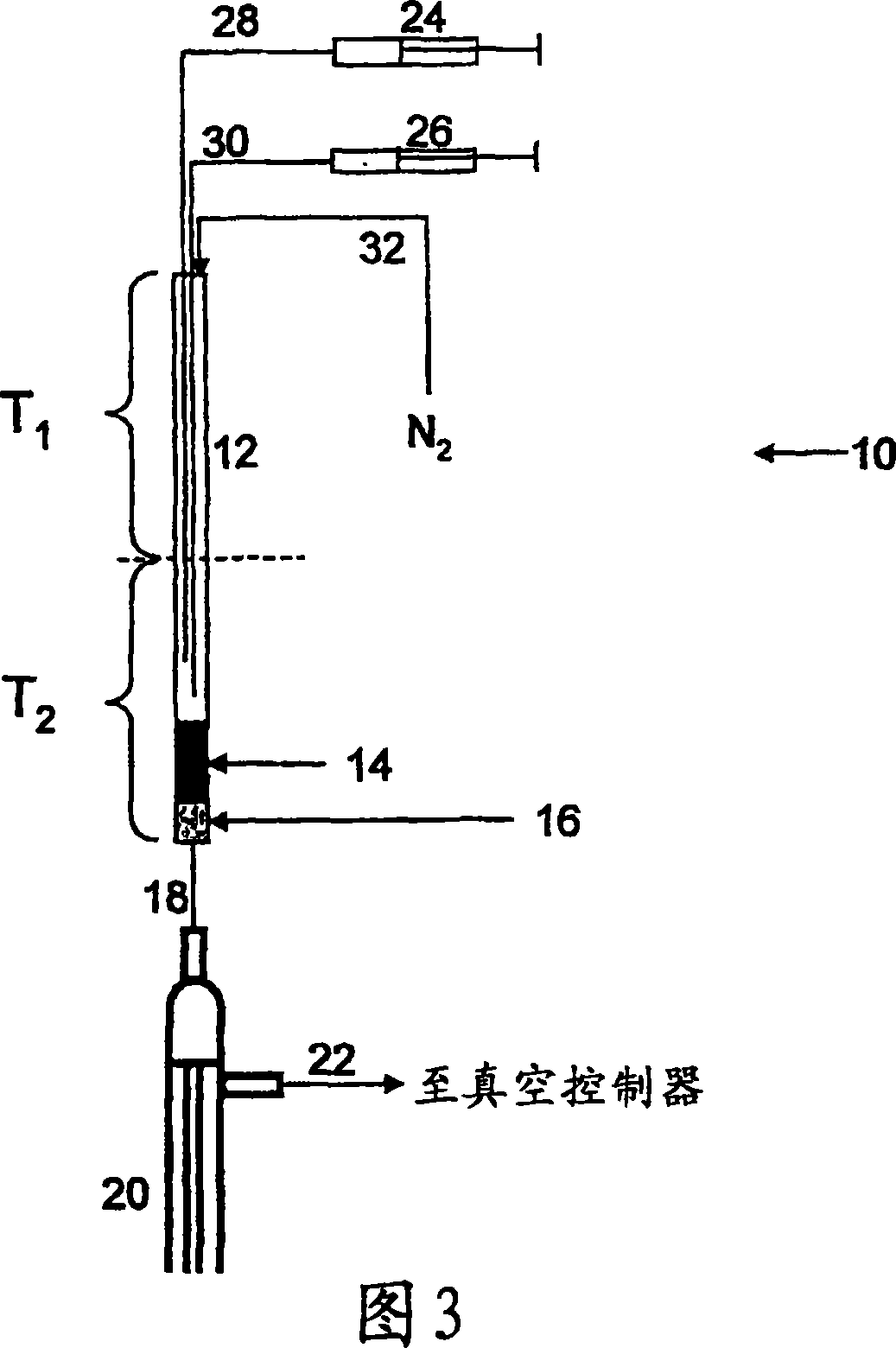

[0082] An approximately 3 mL stainless steel batch reactor was filled with 0.2549 grams of electronic grade magnesia (eMgO) and 0.2543 grams of a solution of 75 wt% 2-bromododecane and 25 wt% octadecane (as internal standard). Stir with a stainless steel spatula to mix the solids and liquids, then add 0.3065 grams of ethylene glycol (EG). The reactor was sealed and agitated with a vibrating shaker for 5 minutes, then placed in a preheated oven at 225°C for 6 hours. Once cooled, the organics were extracted with ethanol and analyzed by gas chromatography and mass spectrometry to characterize and quantify the product and starting material. Analysis showed that 49% of the 2-bromododecane was converted to product. The product consisted of 56% olefins, 3% alcohols, 40% monoethoxylates and 1% ketones.

Embodiment 2

[0084] An approximately 3 mL stainless steel batch reactor was filled with 0.2531 g of copper(II) oxide (CuO) and 0.2500 g of a solution of 75 wt% 2-bromododecane and 25 wt% octadecane (as internal standard). Stir with a stainless steel spatula to mix the solids and liquids, then add 0.0976 grams of EG. The reactor was sealed and agitated with a vibrating shaker for 5 minutes, then placed in a preheated oven at 225°C for 6 hours. Once cooled, the organics were extracted with ethanol and analyzed by gas chromatography and mass spectrometry to characterize and quantify the product and starting material. Analysis showed 97% conversion of 2-bromododecane to product. The product consists of 58% olefins, 9% alcohols, 32% monoethoxylates and 1% ketones.

Embodiment 3

[0086] An approximately 3 mL stainless steel batch reactor was filled with 0.2501 g of copper(II) oxide (CuO) and 0.2538 g of a solution of 75 wt% 2-bromododecane and 25 wt% octadecane (as internal standard). Stir with a stainless steel spatula to mix the solids and liquids, then add 0.1002 grams of EG. The reactor was sealed and agitated with a vibrating shaker for 5 minutes, then placed in a preheated oven at 225°C for 3 hours. Once cooled, the organics were extracted with ethanol and analyzed by gas chromatography and mass spectrometry to characterize and quantify the product and starting material. Analysis showed that 42% of the 2-bromododecane was converted to product. The product consisted of 31% olefins, 5% alcohols, 63% monoethoxylates and 1% ketones.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com