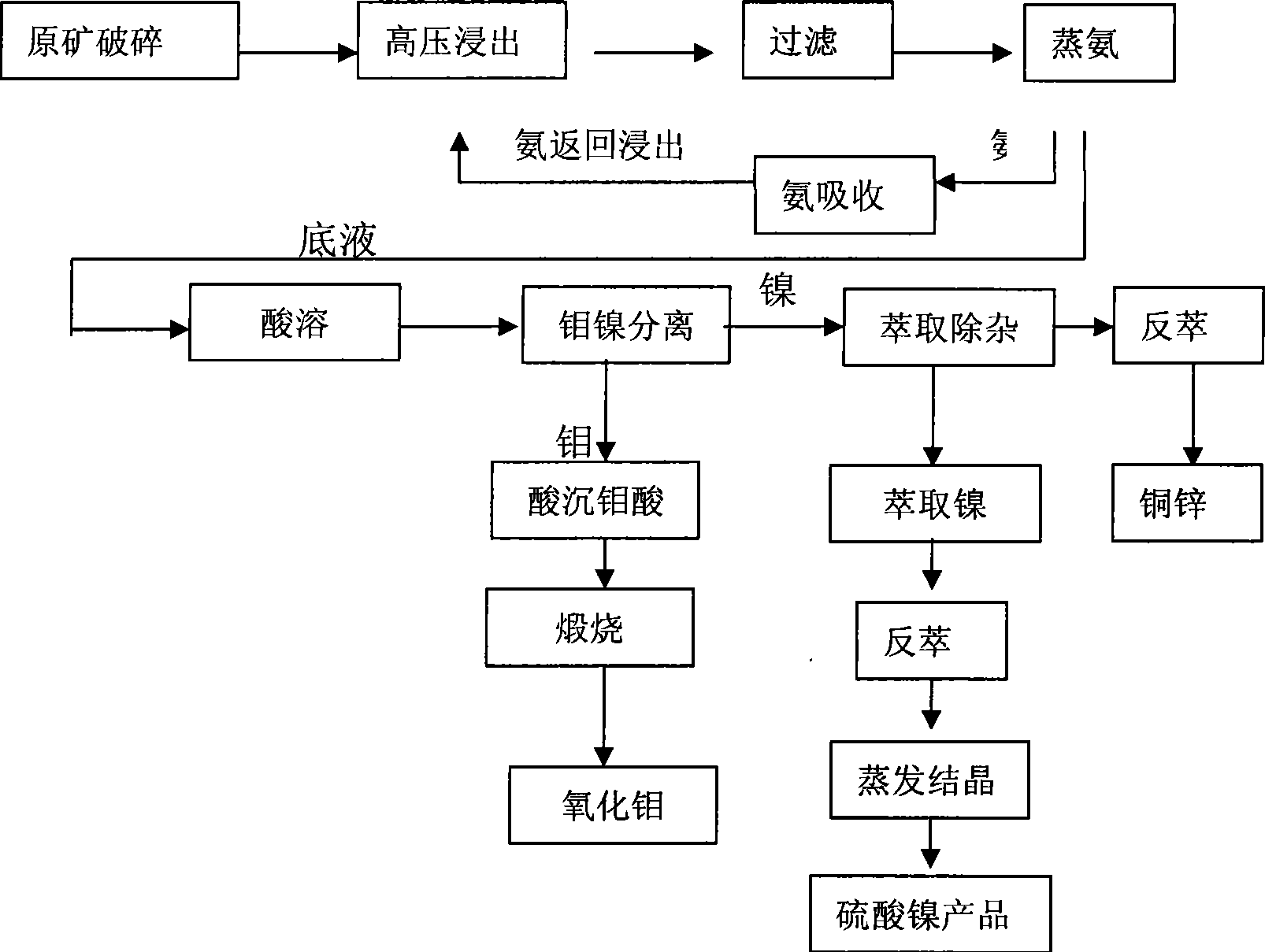

Process for extracting and separating nickel-phase form bone coal ore by high pressure oxygen-ammonia leaching

A high-pressure oxygen, stone coal mine technology, applied in the field of molybdenum-nickel symbiotic ore extraction of molybdenum and nickel salts, can solve the problems of environmental pollution, low molybdenum recovery rate, environmental impact, etc., and achieves the improvement of operating environment, high recovery rate, and pollution reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Grind nickel-molybdenum ore containing Mo2.75%, Ni0.85% until 80% passes through a 200-mesh sieve, weigh 100g, add 25% industrial ammonia 200g, water 100g, feed oxygen, at 1.5mPa, temperature 80°C Next, react for 5 hours. Then filter, dry filter residue, slag weight 88g, analyze molybdenum nickel grade in the slag, be respectively: Mo0.1%, Ni0.05%, molybdenum, nickel slag meter leaching rate are respectively: Mo leaching rate 96.8%, Ni leaching rate 94.8%.

Embodiment 2

[0027] Grind nickel-molybdenum ore containing Mo8.4%, Ni3.32% until 80% passes through a 200 mesh sieve, weigh 100g, add 25% industrial ammonia water 300g, feed oxygen, at 3.0mPa, temperature 180°C, react 9 hours. Then filter and dry the filter residue, the residue weight is 71.6g, the grade of molybdenum and nickel in the analysis residue is: Mo0.62%, Ni0.22%, the leaching rate of molybdenum and nickel slag is respectively: Mo leaching rate 94.7%, Ni leaching rate The rate is 95.2%.

Embodiment 3

[0029] Grind 27 tons of ore to 200 mesh, the average grade of ore powder is: Mo3.02%, Ni2.47%, pulping according to the liquid-solid volume ratio of 3 / 1, the concentration of ammonia water is 14%, at 2.0mPa, the temperature is 100℃ The average reaction time is 4 hours; filter, wash the residue with water, pass the filtrate through the ammonia distillation system to recover ammonia water; then, add sulfuric acid to dissolve to pH 3.0, extract molybdenum with 10% TFA (tri-fatty amine), wash and extract molybdenum with water Saturate the organic phase, then back-extract molybdenum with ammonia water to obtain ammonium molybdate solution, acid-precipitate ammonium tetramolybdate or molybdenum acid; extract molybdenum aqueous phase with 20% P2O4 at pH 4.0 to extract copper and zinc, wash and co-extract nickel, and back-extract copper Zinc, get the by-product solution of copper and zinc sulfate, remove copper and zinc solution and extract nickel with 20% P2O4 at pH 6.0, back-extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com