Wire grating wideband polarizer and method of producing the same

A metal wire grid and polarizer technology, applied in the field of metal wire grid polarizer and its preparation, can solve the problems of complex polarizer structure, increased process difficulty, no solution to polarizer, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

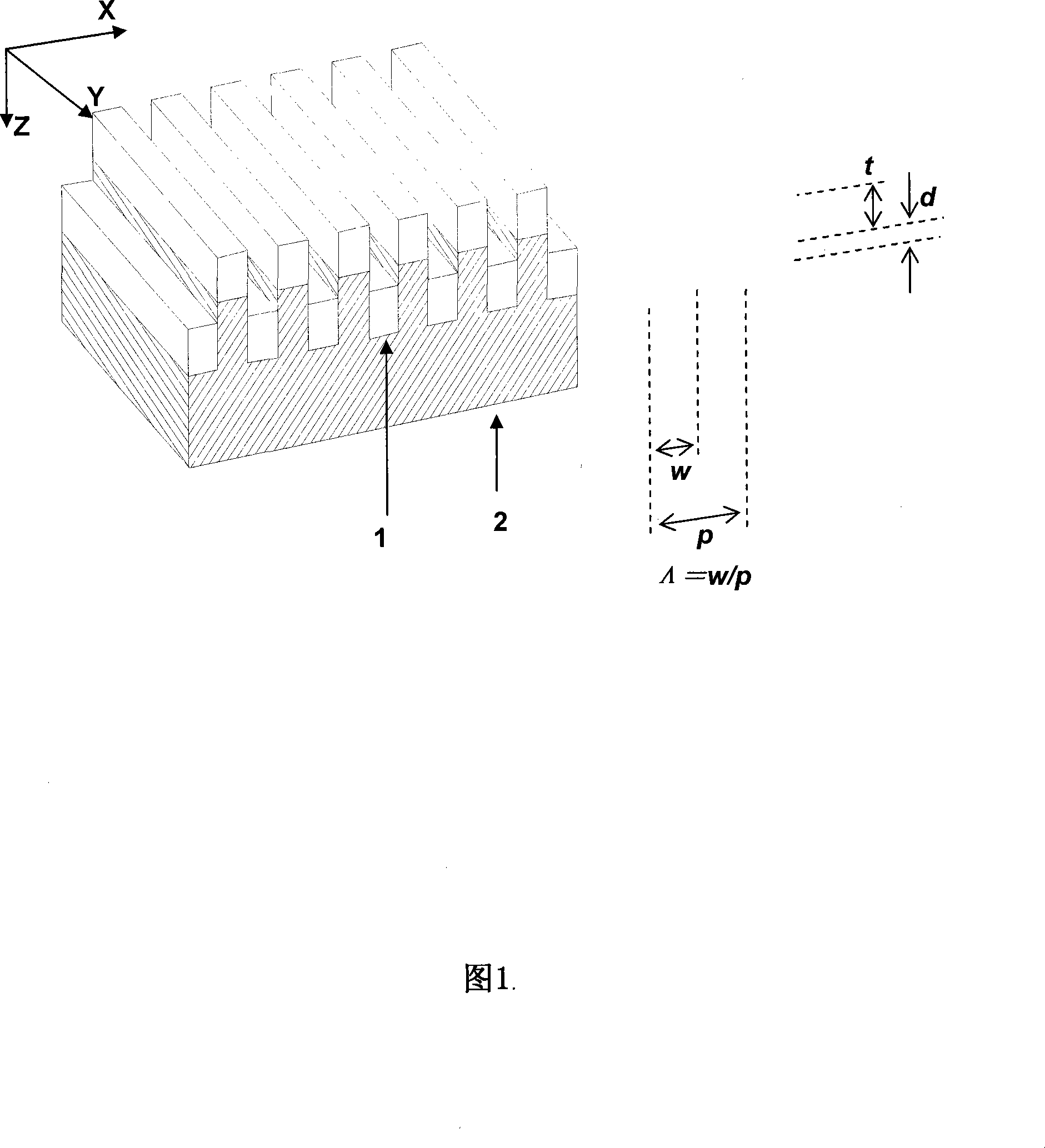

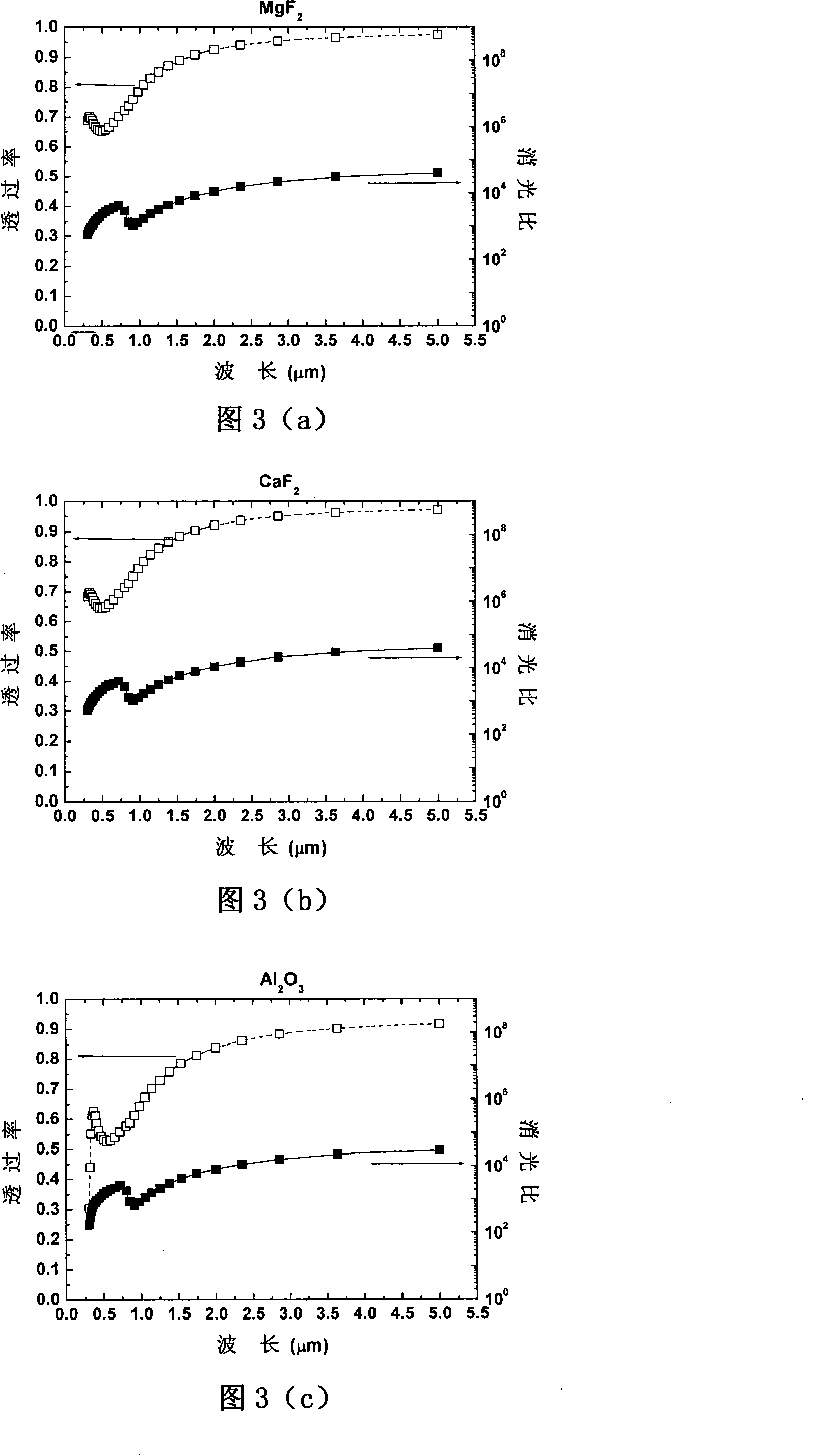

[0025] The design of metal aluminum nanowire grid polarizer structure and the analysis of its optical properties are completed by finite difference time domain (FDTD) algorithm. FIG. 1 is a schematic diagram showing the structure of the broadband polarizer of the present invention. The substrate in the figure is selected from optical materials that are transparent in the ultraviolet to infrared bands, such as calcium fluoride, magnesium fluoride, and aluminum oxide. Aluminum materials with high extinction ratio and high luminous flux are used in the selection of metal nanowire grid materials.

[0026] Marked in the figure are: metal aluminum nano wire grid 1, polarizer substrate 2, wire grid period length p, etching width w, duty ratio Λ=w / p, wire grid thickness t, layer spacing d.

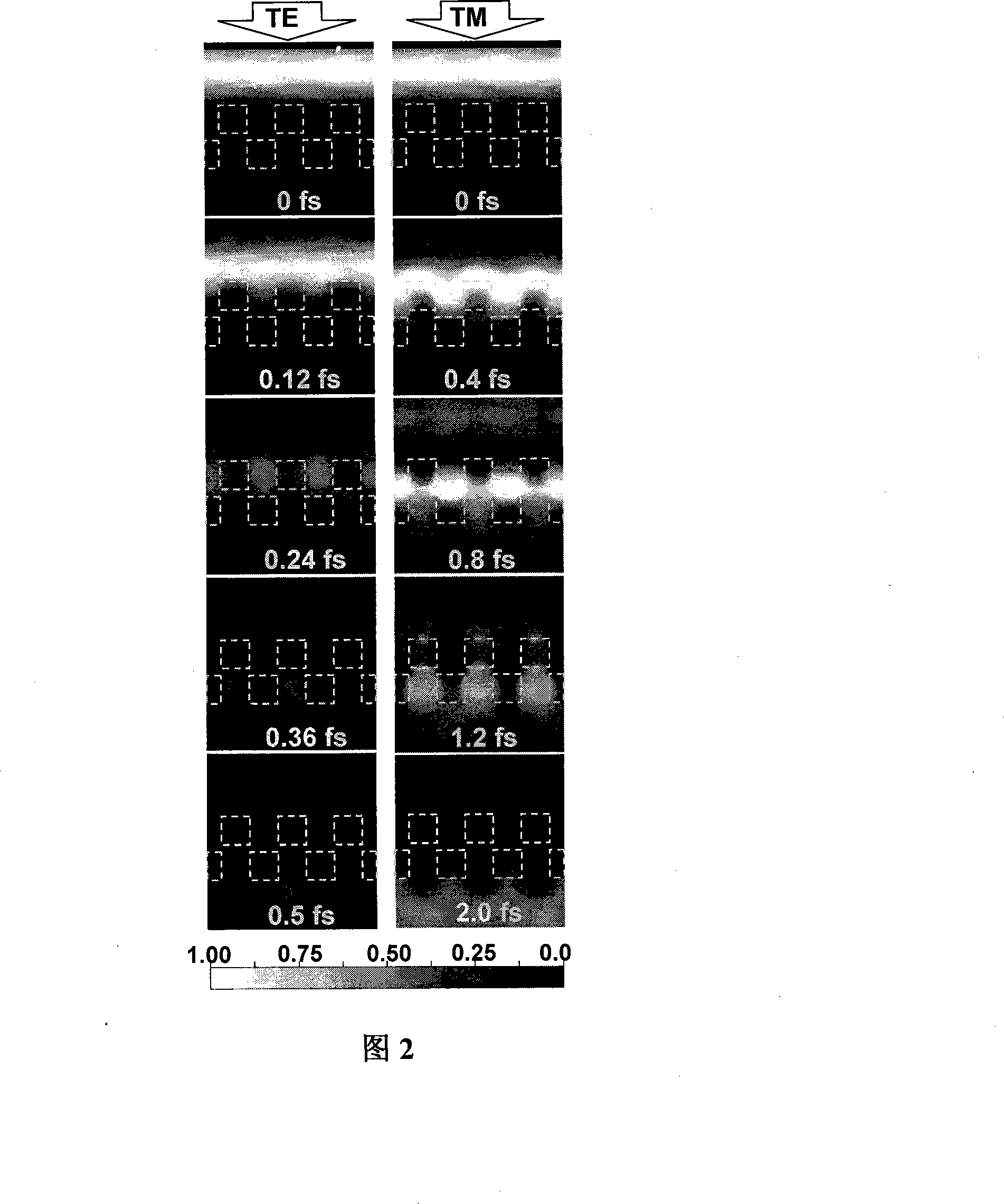

[0027] Fig. 2 shows the light transmission process when light of different polarization states simulated by the FDTD algorithm passes through the polarizer with the structure shown in Fig. 1 . I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com