Integrated treatment method and device for crude oil electric desalting device oil-containing cutting water

A comprehensive treatment and electric desalination technology, applied in centrifugal separation of water/sewage treatment, grease/oily substance/float removal device, separation method, etc., can solve the problems of inconvenient operation, complex structure, large investment, etc. The effect of convenience, simple device structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

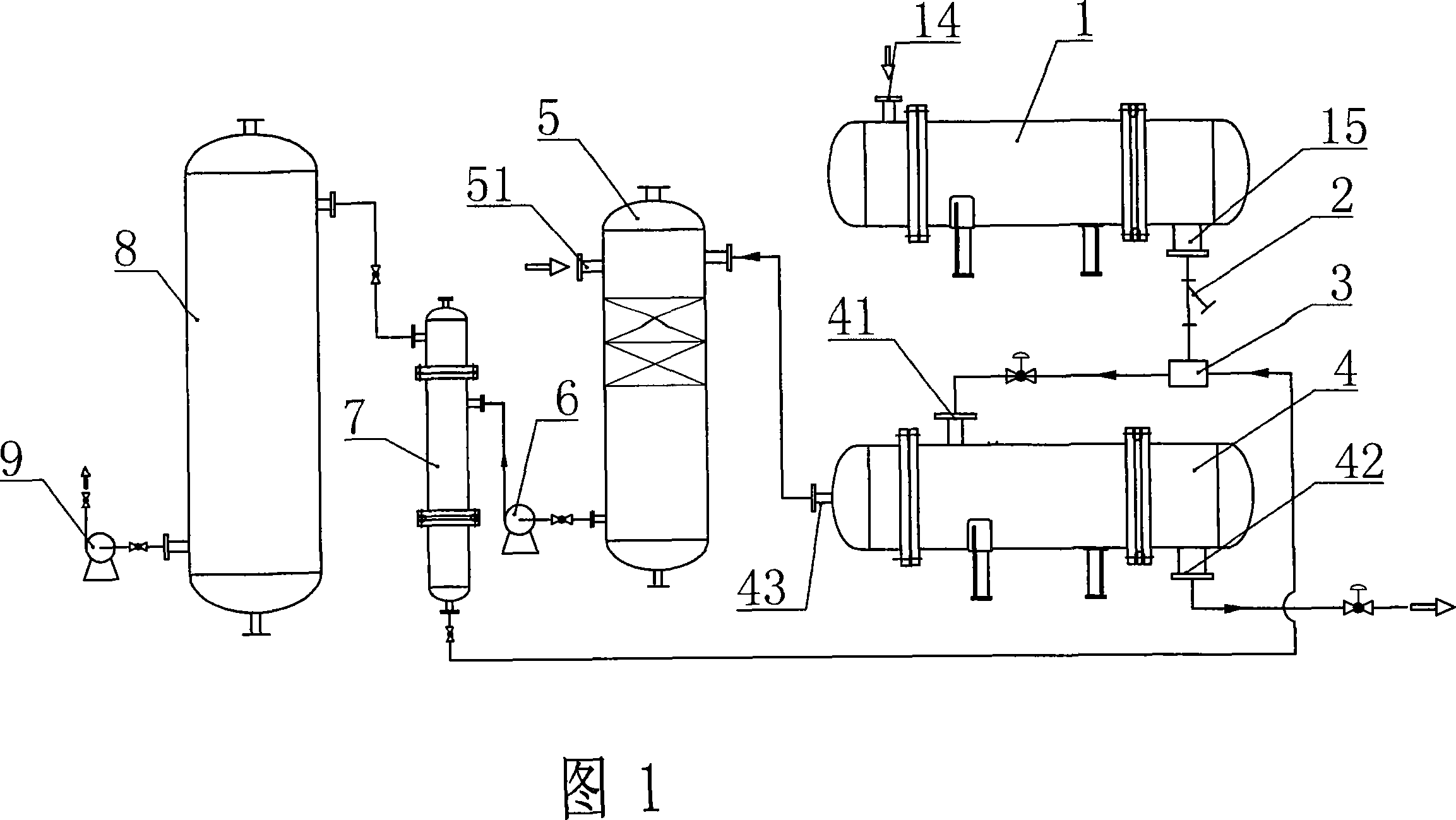

Embodiment 1

[0025] Referring to Figure 1, after the electric desalination cut water is cooled to below 100°C by the heat exchanger 1, it enters the sewage cyclone degreaser 4 through the filter 2 and the mixer 3, and is centrifugally separated by the swirl tube in the cyclone 4 , the oily sewage is separated into watery sewage oil and saline sewage, the saline sewage is directly discharged outside, and the watery sewage oil overflows into the intermediate demulsification tank 5 . The intermediate demulsification tank 5 is equipped with multi-layer sloping plates or structured packing to mechanically demulsify the emulsified sewage oil. The intermediate demulsification tank 5 should also have a demulsifier injection port. Aids in demulsification. After the water-containing sewage oil stays in the intermediate demulsification tank for 10 to 60 minutes, it is boosted by the frequency conversion speed-regulating pump 6 and sent to the sewage oil cyclone dehydrator 7 for cyclone dehydration, a...

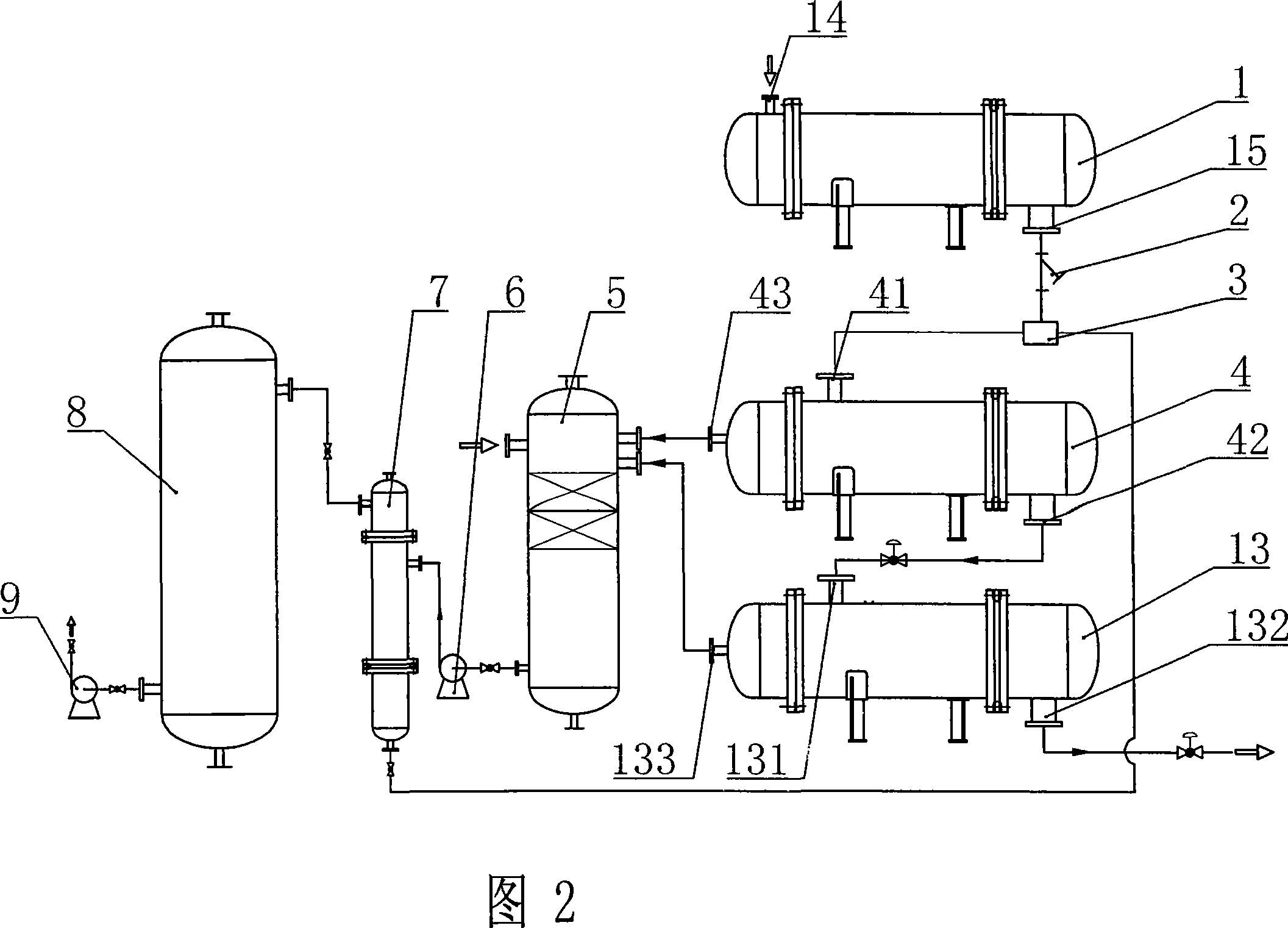

Embodiment 2

[0027] Referring to Figure 2, when the electric desalination cutting water has a high oil concentration, a two-stage cyclone oil removal process is adopted. After the electric desalination cutting water is cooled to below 100°C by the heat exchanger 1, it enters the first-stage sewage cyclone degreaser 4 through the filter 2 and the mixer 3. Under the centrifugal separation of the swirl tube in the cyclone, the oily sewage Separation into water-containing sewage oil and low-oil-containing saline sewage, water-containing sewage oil enters the intermediate demulsification tank 5, low-oil-containing saline sewage directly enters the secondary sewage cyclone degreaser 13 to continue oil-water separation, and is separated into water-containing sewage oil and Saline sewage, the saline sewage is directly discharged outside, and the oily sewage overflows to the intermediate demulsification tank 5 . The intermediate demulsification tank 5 is equipped with multi-layer sloping plates or ...

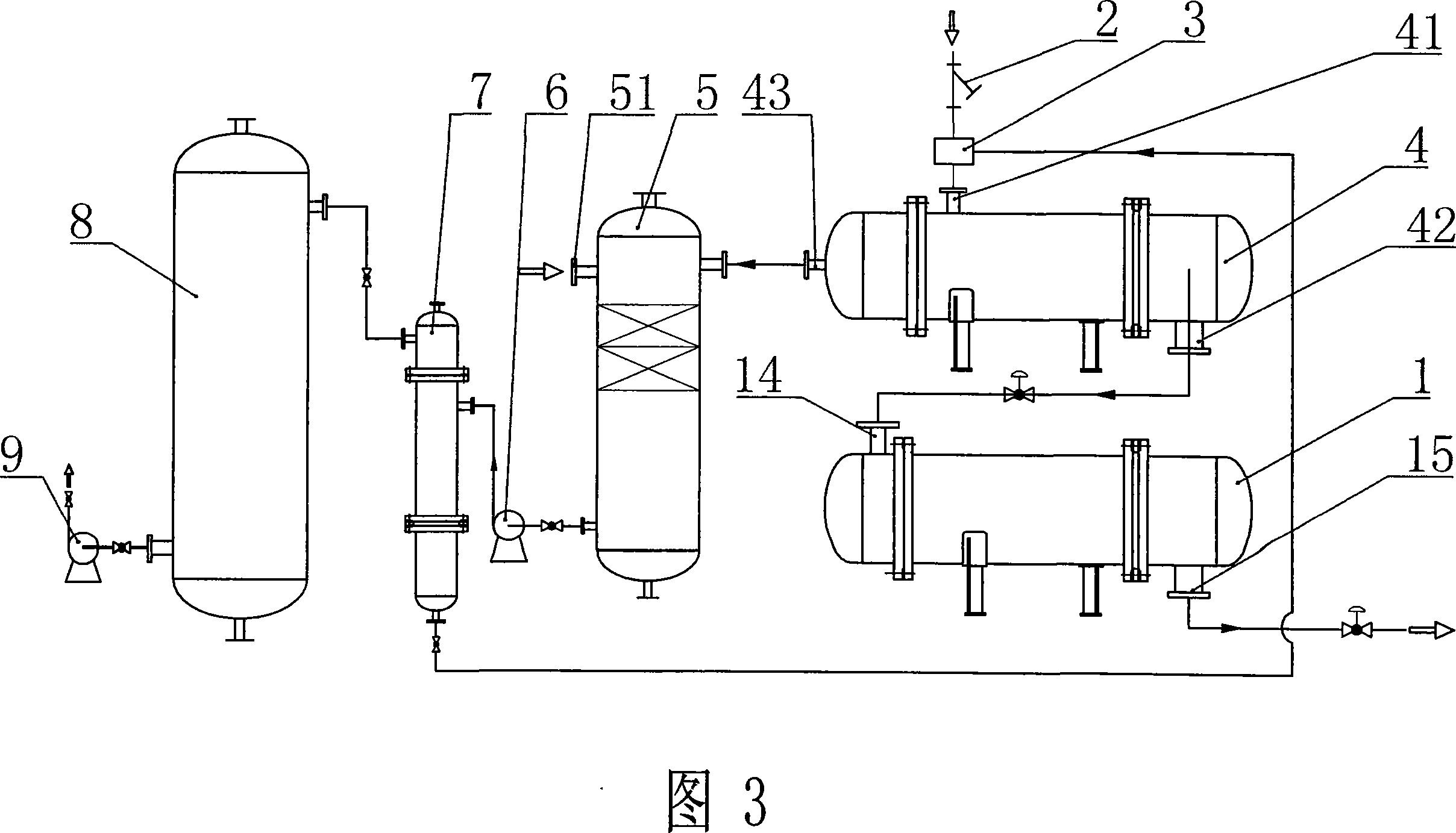

Embodiment 3

[0029] Referring to Figure 3, the electric desalination cut water enters the sewage cyclone degreaser 4 through the filter 2 and the mixer 3, and under the centrifugal separation of the swirl tube in the cyclone, the oily sewage is separated into watery sewage oil and low oil content. Saline sewage, water-containing sewage oil enters the intermediate demulsification tank 5, and low-oil-contained saline sewage enters the heat exchanger 1 to cool down to below 100°C before being discharged. The oily sewage overflowed from the cyclone degreaser 4 overflows to the intermediate demulsification tank 5 through the overflow outlet. The intermediate demulsification tank 5 is equipped with multi-layer inclined plates or structured packing to mechanically demulsify the emulsified waste oil. The intermediate demulsification tank 5 should also have a demulsifier injection port. When the emulsification of the water-containing sewage oil is serious, inject a chemical demulsifier Aids in demu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com