Technique for preparing Li doping ZnO ceramic target material

A preparation process and ceramic target material technology, which is applied in the field of Li-doped ZnO ceramic target material preparation process, and can solve the problems of easy agglomeration, uneven doping, and low purity of the target material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

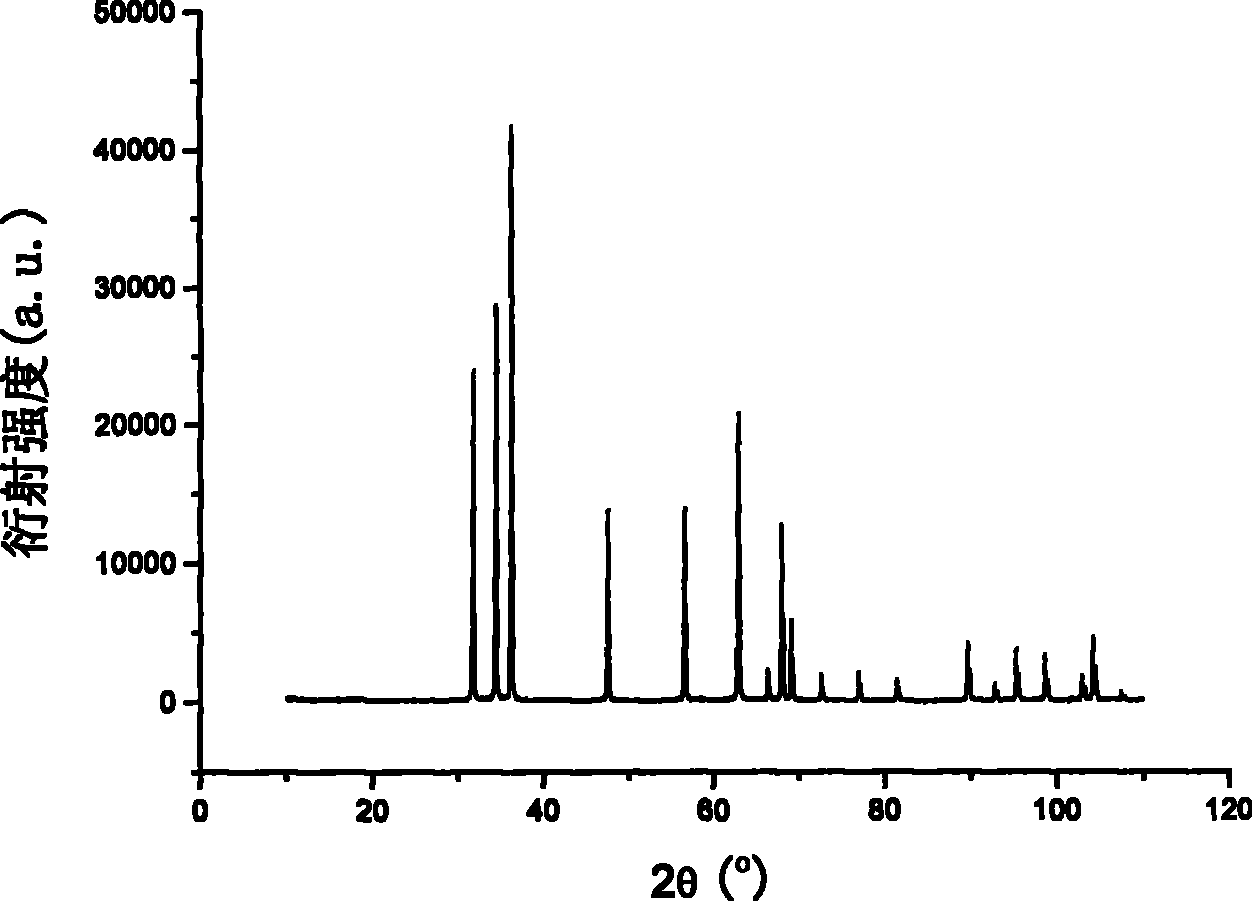

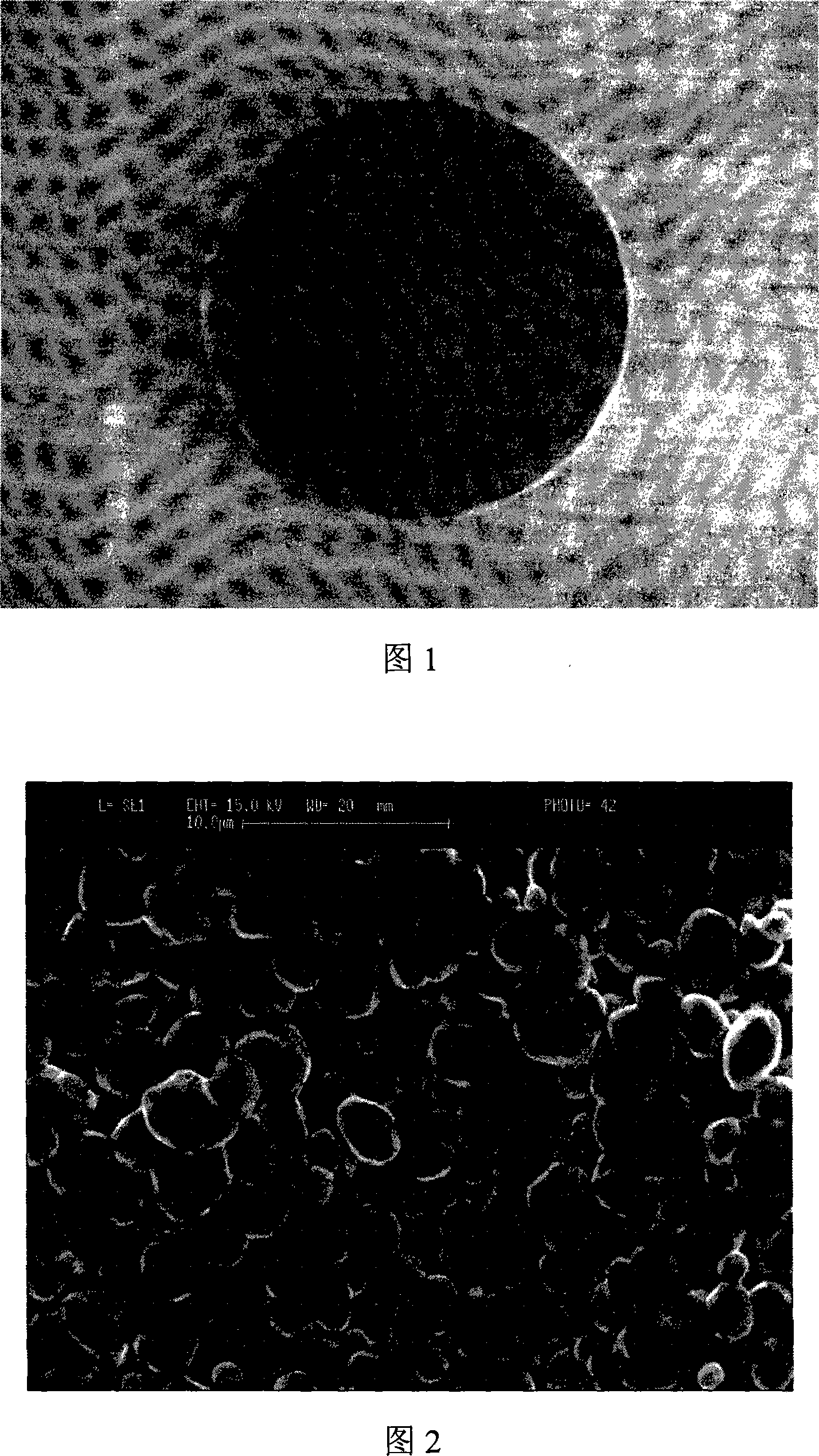

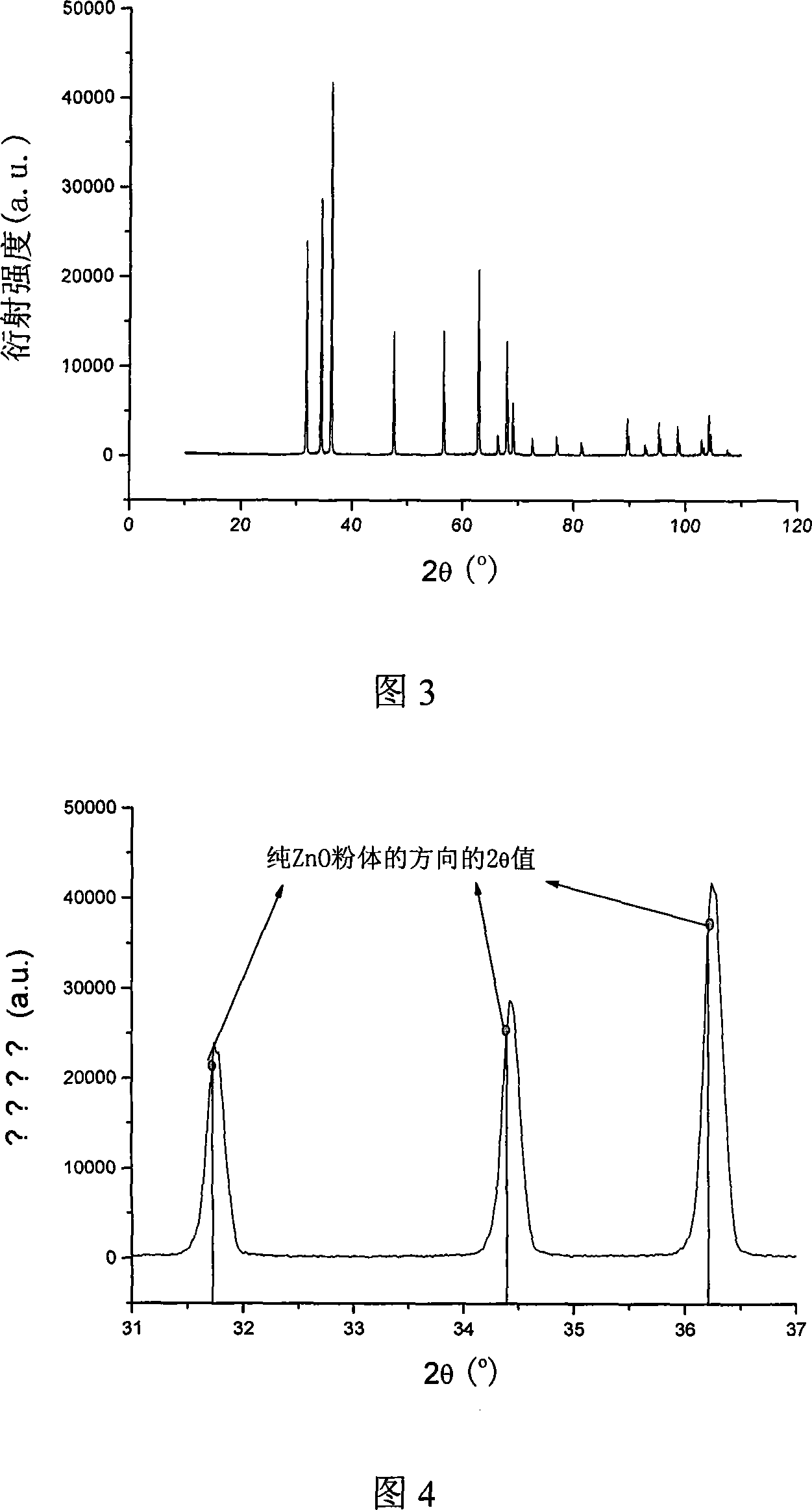

[0014] Mix zinc nitrate, lithium nitrate, urea and glycine evenly in a molar ratio of 25:1:30:10 and put them into a beaker, inject deionized water and stir evenly until the solution is transparent without sediment, pour the solution into the evaporation Put it in a dish and heat it on a horse boiling furnace. The solution is in the form of a gel, and it should be placed violently until it burns to form a Li-doped ZnO powder. Put Li-doped ZnO powder in a corundum bowl and grind for 30min, then put it into a spark plasma sintering furnace, pre-press to 30MPa, when the vacuum degree reaches 7Pa, start heating up, the heating rate is 100℃ / min, until the temperature is When the temperature is 900°C, add an axial pressure of 30MPa. When the temperature is 1000°C, keep it warm for 3 minutes. After the heat preservation is over, release the pressure quickly, and cool naturally to room temperature and take it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com