Fermentation culture medium for biologically synthesizing 7alpha, 15alpha-dihydroxyandrostenolone

A technology of hydroxyandrostenolone and fermentation medium, which is applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of low conversion efficiency, low substrate feeding concentration, low conversion rate, etc., and achieve low conversion rate. High, solve the effect of low substrate feeding concentration and reduce the cost of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

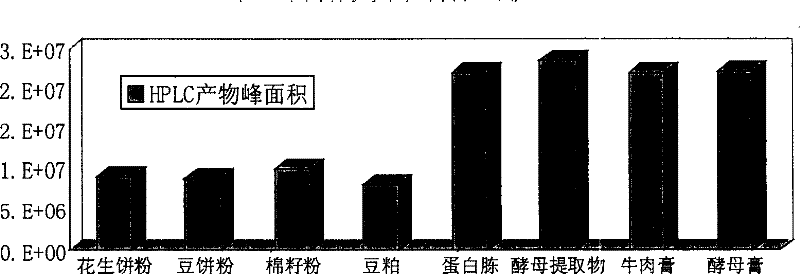

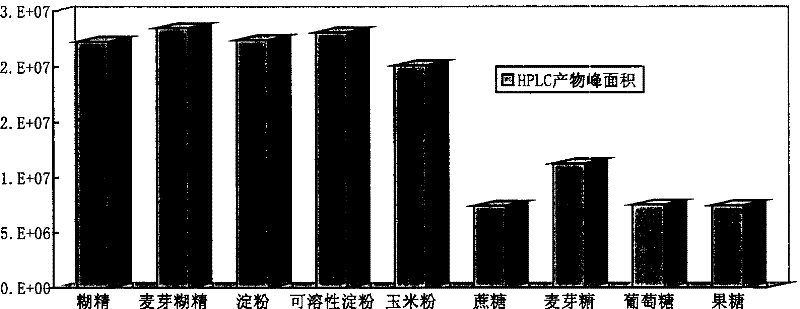

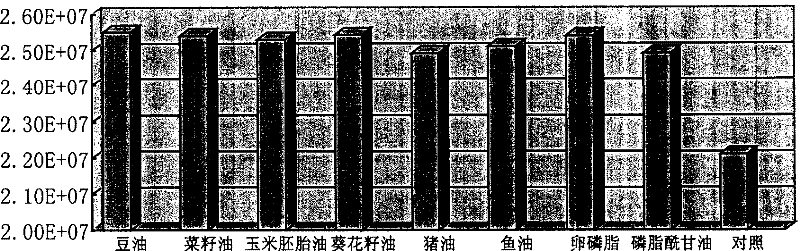

Method used

Image

Examples

Embodiment 1

[0025] culture medium

[0026] Slant medium: PDA medium (200g potato juice 1000ml, glucose 20g, agar 20g), sterilized at 121°C for 20min.

[0027] Seed medium: peanut cake powder 10g / L; dextrin 30g / L; KCl 1g / L; (NH 4 ) 2 HPO 4 1g / L; K 2 HPO 4 1g / L; MgSO 4 ·6H 2 O1g / L. pH5.5, sterilized at 121°C for 20min.

[0028] Fermentation medium: yeast extract 10g / L; maltodextrin 35g / L; sunflower oil 5g / L; KCl 1g / L; (NH 4 ) 2 HPO 4 1g / L; K 2 HPO 4 1g / L; MgSO 4 ·6H 2 O1g / L. pH5.5, sterilized at 121°C for 20min.

[0029] Transformation process: Place the slant of the inoculated bacteria in a constant temperature incubator at 28°C, cultivate for 6 days to obtain mature spores, and then inoculate the mature spores in a 250ml shaker flask containing 30ml of seed medium, at 30°C, 230rpm Cultivate on a shaker for 3 days to obtain mature seeds. The seeds obtained are inserted into a 750ml shaker flask with 100ml fermentation medium with 10% inoculum size, placed at 30°C, 230r / min...

Embodiment 2

[0031] The slant medium and seed medium are the same as in Example 1.

[0032] Fermentation medium: peptone 20g / L; maltodextrin 30g / L; lard 5g / L; KCl1g / L; (NH 4 ) 2 HPO 4 1g / L; K 2 HPO 4 1g / L; MgSO 4 ·6H 2 O1g / L. pH5.5, sterilized at 121°C for 20min.

[0033] The conversion process is the same as in Example 1, and the final conversion rate is 85.1%.

Embodiment 3

[0035] The slant medium and seed medium are the same as in Example 1.

[0036] Fermentation medium: beef extract 30g / L; dextrin 20g / L; lecithin 1g / L; KCl 1g / L; (NH 4 ) 2 HPO 4 1g / L; K 2 HPO4 1g / L; MgSO 4 ·6H 2 O1g / L. pH5.5, sterilized at 121°C for 20min.

[0037] The conversion process is the same as in Example 1, and the final conversion rate is 85.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com